Cutter dynamic reliability and failure rate method based on random process

A stochastic process and failure rate technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that cannot reflect the changing laws of tool reliability and cutting time, insufficient accuracy and precision, and cost-effective Large time and financial resources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0116] The experimental sample is a YT05 cemented carbide blade, and 5 batches of blades are used for the experiment. The experiment was carried out according to the size specified in the GB3851-83 standard, and the bending strength of YT05 was measured on the INSTRON2382 universal testing machine with a loading speed of 200N / mm.

[0117] Critical fatigue stress σ t The distribution of can be determined by the formula (11), and the tensile strength in the formula (11) can be measured by the flexural strength of the experiment. The experimental data and calculation results are shown in Table 1:

[0118] Table 1 Bending strength test data

[0119]

[0120]

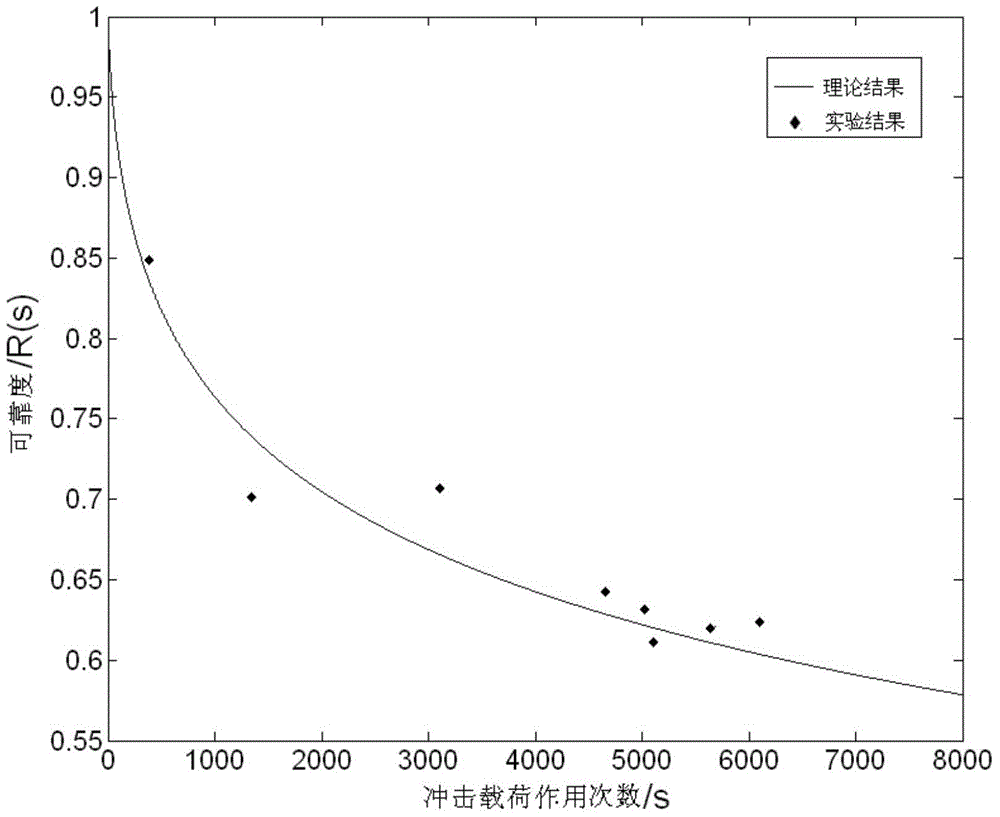

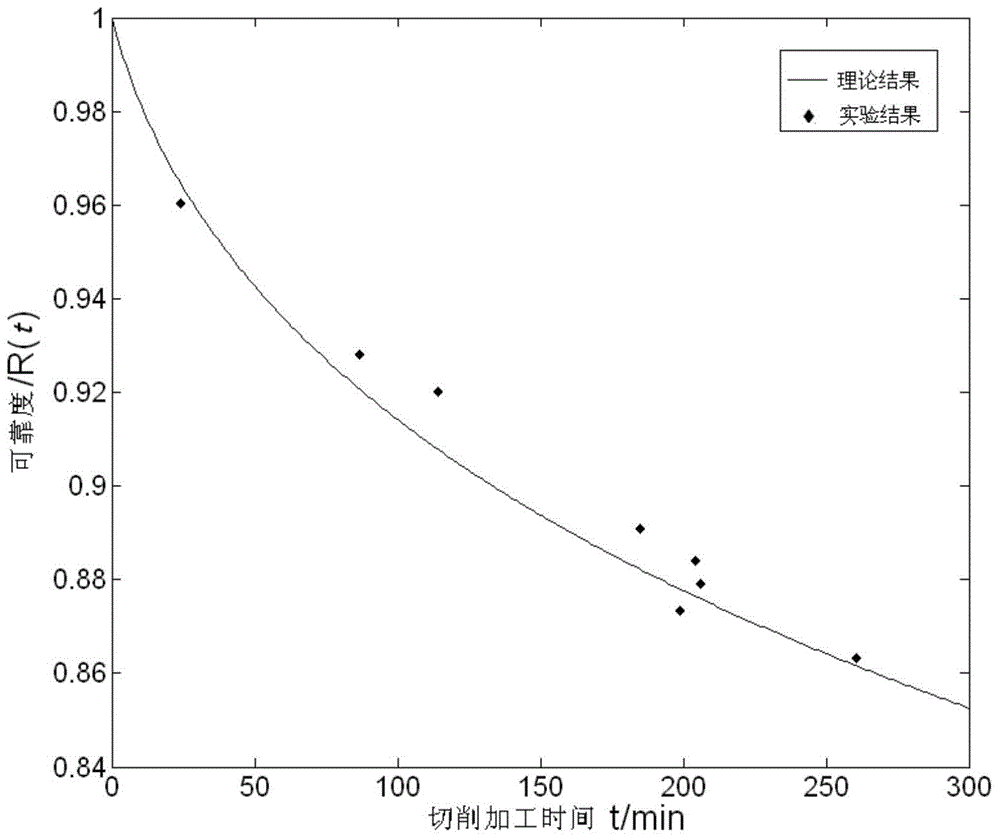

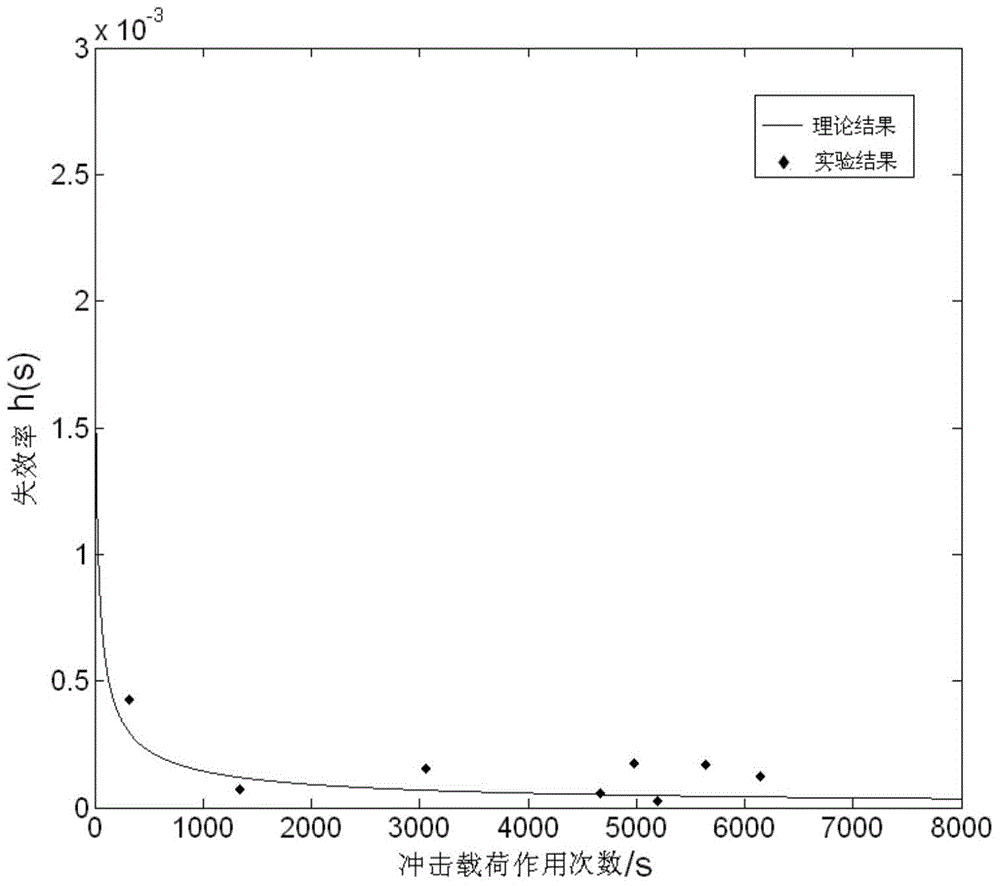

[0121] The fracture toughness of YT05 cemented carbide was tested by the SENB method; n and A can be measured from the I-type crack growth rate, Y can be calculated by the existing method, σ t0 、m t and σ tu It can be obtained by the Weibull parameter estimation method, and the test and calculation results are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com