Display substrate, manufacturing method thereof and transparent display device

A display substrate and substrate technology, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as low cut-off, complex structure of display devices, and affecting the production efficiency of display devices

- Summary

- Abstract

- Description

- Claims

- Application Information

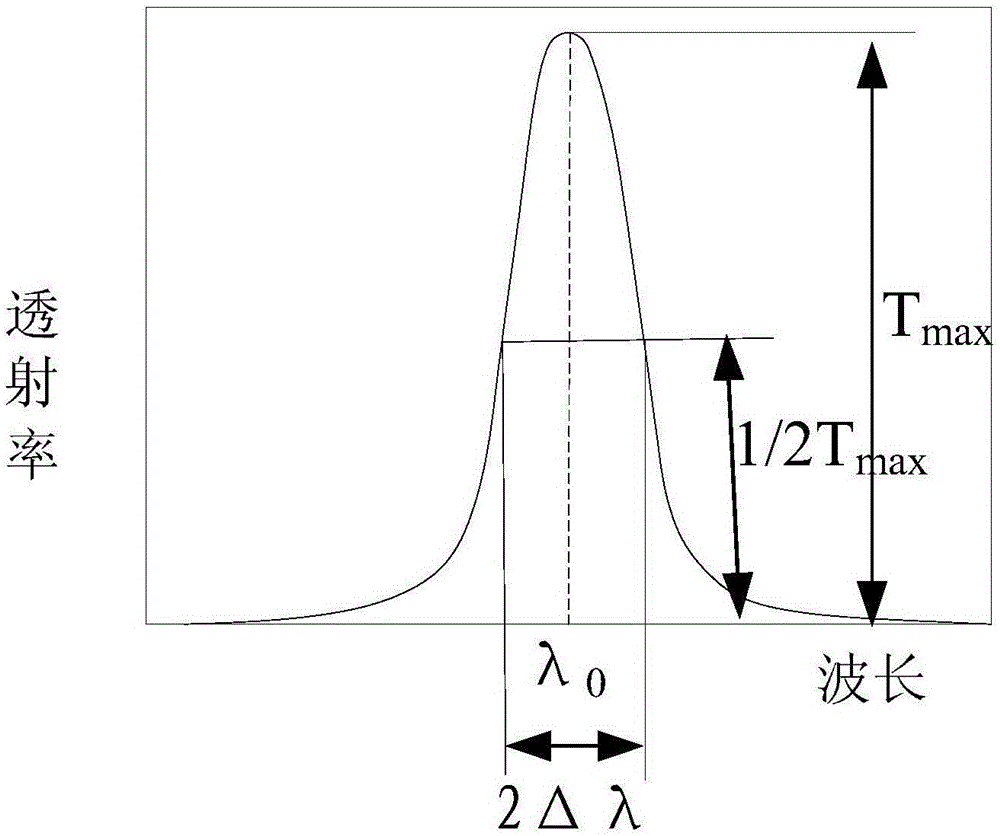

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

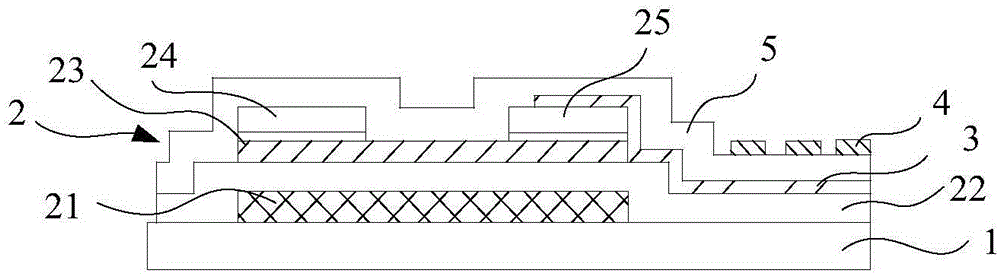

[0057] In addition, an embodiment of the present invention also provides a method for preparing a display substrate, the method including the following steps:

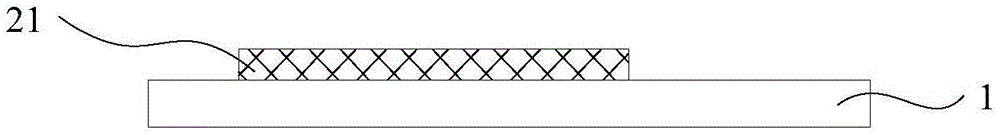

[0058] providing a substrate;

[0059] forming a first metal layer in the pixel area on the substrate;

[0060] A passivation layer is formed on the first metal layer, and the thickness of the passivation layer of multiple sub-pixel regions located in the same pixel region is different;

[0061] A second metal layer is formed on the passivation layer; and the first metal layer, the passivation layer and the second metal layer form a Faber cavity, and the Faber cavity allows light transmission of different wavelengths according to the thickness of the passivation layer. Pass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com