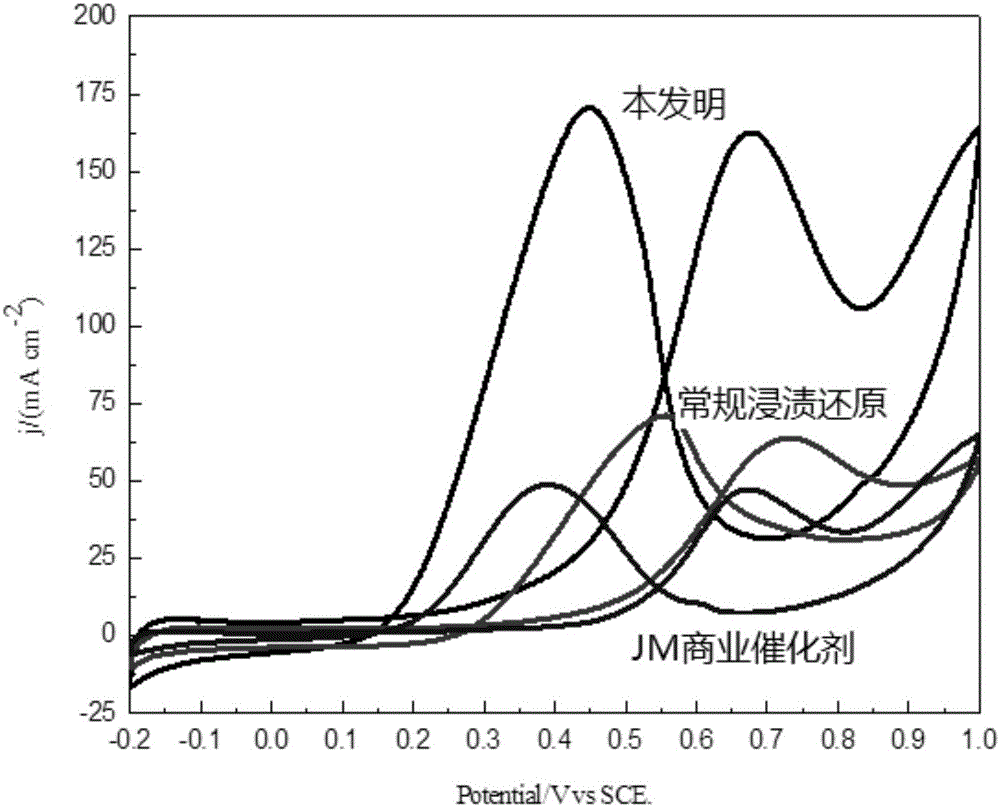

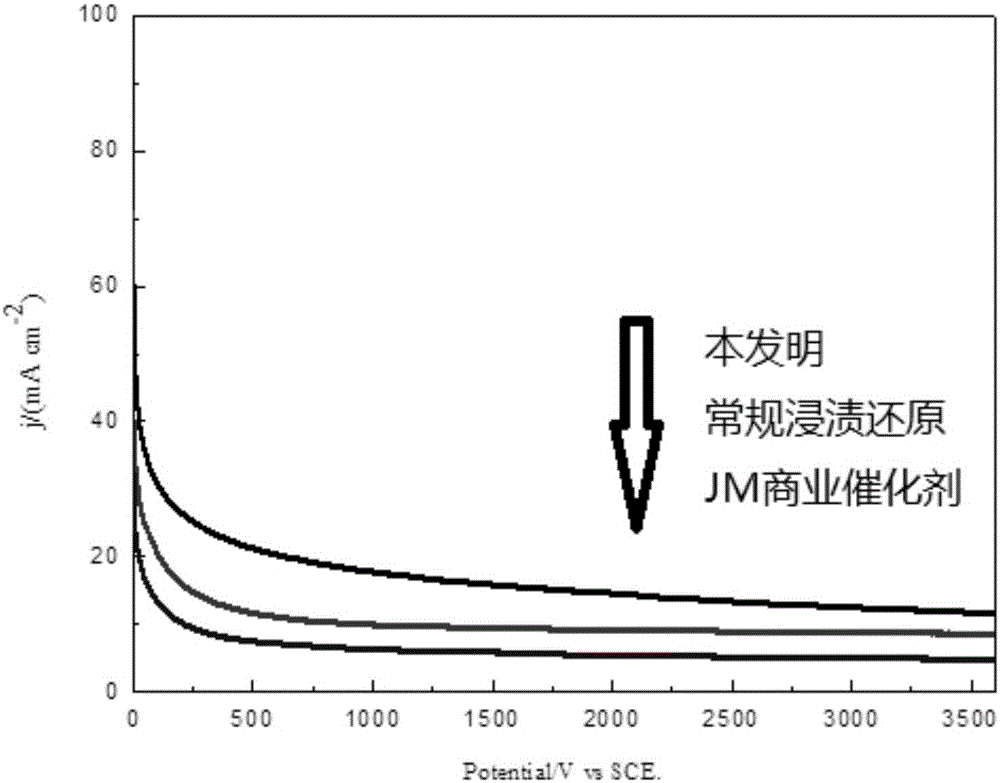

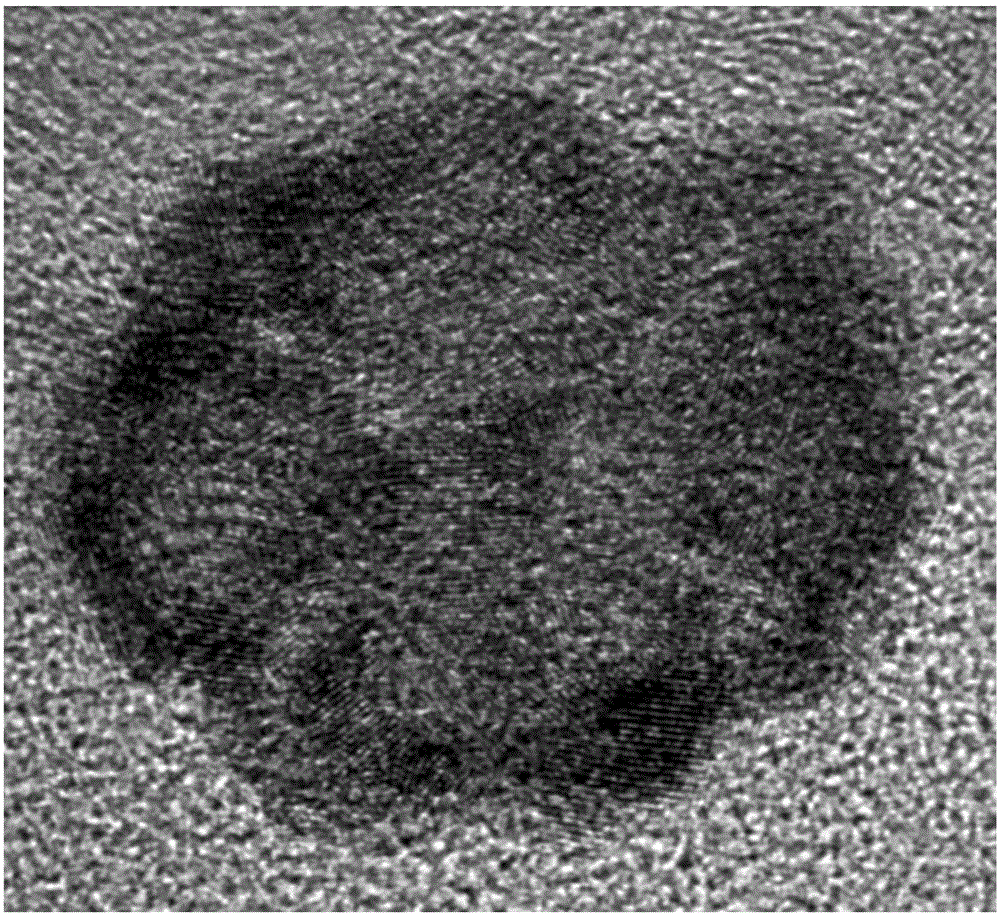

Preparation method of direct ethanol fuel cell catalyst with hollow structure

A technology of fuel cells and catalysts, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of poor stability of Pt-Ni/C catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing an anode Pt-Ni / C catalyst for a direct ethanol fuel cell, specifically comprising the following steps:

[0026] (1) 0.2718g trisodium citrate stabilizer is dissolved in 20ml deionized water to form a stable solution;

[0027] (2) 2ml, 0.02MH 2 PtCl 6 ·6H 2 O platinum precursor solution and 2.65ml, 0.05MNiC 4 H 6 O 4 ·4H 2 O nickel precursor solution is added to above-mentioned solution;

[0028] (3) The solution of (2) was magnetically stirred for 1 h and then added with the pre-treated carbon slurry, and the treatment method of the carbon slurry was: 0.0235 g of XC-72R was added to 10 ml of anhydrous ethanol solution and ultrasonicated for 30 min;

[0029] (4) 0.1 g of NaBH 4 The solution of the reducing agent added to 10 ml of deionized water was added dropwise to the solution of (3), the whole dropping process was carried out in an ice bath, and the magnetic stirring was carried out for 2h;

[0030] (5) The solution of (4) was suction-...

Embodiment 2

[0034] A method for preparing an anode Pt-Ni / C catalyst for a direct ethanol fuel cell, specifically comprising the following steps:

[0035] (1) 0.2718g trisodium citrate stabilizer is dissolved in 20ml deionized water to form a stable solution;

[0036] (2) 2ml, 0.02MH 2 PtCl 6 ·6H 2 O platinum precursor solution and 2.65ml, 0.05MNiC 4 H 6 O 4 ·4H 2 O nickel precursor solution is added to above-mentioned solution;

[0037] (3) The solution of (2) was magnetically stirred for 1 h and then added with the pre-treated carbon slurry, and the treatment method of the carbon slurry was: 0.0235 g of XC-72R was added to 10 ml of anhydrous ethanol solution and ultrasonicated for 30 min;

[0038] (4) 0.1 g of NaBH 4 The solution of the reducing agent added to 10 ml of deionized water was added dropwise to the solution of (3), the whole dropping process was carried out in an ice bath, and the magnetic stirring was carried out for 2h;

[0039] (5) The solution of (4) was suction-...

Embodiment 3

[0043] A method for preparing an anode Pt-Ni / C catalyst for a direct ethanol fuel cell, specifically comprising the following steps:

[0044] (1) 0.2718g trisodium citrate stabilizer is dissolved in 20ml deionized water to form a stable solution;

[0045] (2) 2ml, 0.02MH 2 PtCl 6 ·6H 2 O platinum precursor solution and 2.65ml, 0.05MNiC 4 H 6 O 4 ·4H 2 O nickel precursor solution is added to above-mentioned solution;

[0046] (3) The solution of (2) was magnetically stirred for 1 h and then added with the pre-treated carbon slurry, and the treatment method of the carbon slurry was: 0.0235 g of XC-72R was added to 10 ml of anhydrous ethanol solution and ultrasonicated for 30 min;

[0047] (4) 0.1 g of NaBH 4 The solution of the reducing agent added to 10 ml of deionized water was added dropwise to the solution of (3), the whole dropping process was carried out in an ice bath, and the magnetic stirring was carried out for 2h;

[0048] (5) The solution of (4) was suction-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak current | aaaaa | aaaaa |

| Peak current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com