Active energy ray-curable resin composition, undercoating agent containing same, and molded article

A technology of active energy rays and curable resins, applied in coatings, polyester coatings, etc., can solve problems such as unfavorable working environment, whitening appearance, incompatibility, etc., and achieve good appearance, excellent storage stability, and compatibility good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

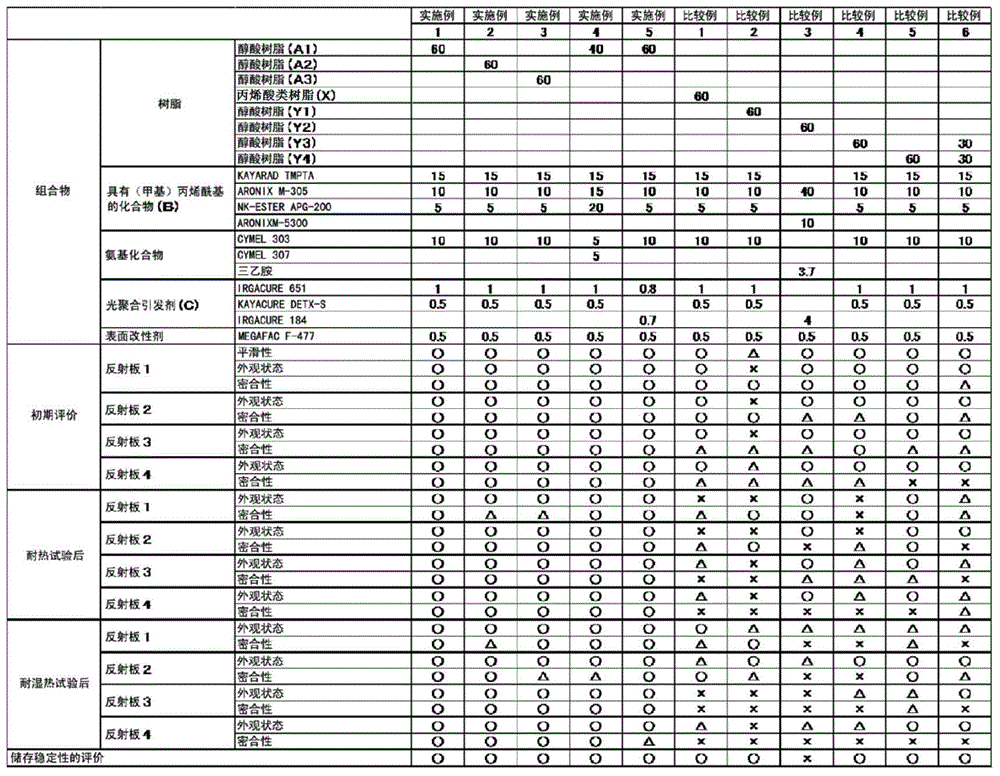

Examples

Embodiment

[0065] Hereinafter, specific synthesis examples and examples are given to describe the present invention in more detail. Hereinafter, unless otherwise specified, "part" and "%" are based on mass.

[0066] [Measurement method of mass average molecular weight (Mw) and molecular weight distribution (Mw / Mn)]

[0067] The mass average molecular weight (Mw) and molecular weight distribution (Mw / Mn) were measured by the gel permeation chromatography (GPC) of the following conditions.

[0068] Measuring device: HLC-8220GPC manufactured by Tosoh Corporation

[0069] Column: TSK-GUARDCOLUMNSuperHZ-L by Tosoh Corporation + TSK-GELSuperHZM-M by Tosoh Corporation × 4

[0070] Detector: RI (differential refractometer)

[0071] Data processing: MultiStationGPC-8020modelII manufactured by Tosoh Corporation

[0072] Determination conditions: column temperature 40°C

[0073]Solvent Tetrahydrofuran

[0074] Flow rate 0.35ml / min

[0075] Standard: Monodisperse Polystyrene

[0076] Sample:...

Synthetic example 1

[0078] Add 840 parts of linseed oil, 420 parts of soybean oil, 208 parts of benzoic acid, 525 parts of pentaerythritol, 88 parts of diethylene glycol, and 843 parts of acid anhydride, 85 parts of xylene and 0.5 part of organotitanium compound were blown into the flask with dry nitrogen, and heated to 230-250°C while stirring to carry out dehydration condensation reaction. When the acid value reached 10.0 mgKOH / g, the reaction was stopped, and after cooling to 150° C., a mixed solvent (xylene / toluene=50 / 50 (mass ratio)) was added dropwise to dilute to a solid content of 60%. As a result, an alkyd resin (A1) having a number average molecular weight of 4,200, a mass average molecular weight of 109,000, a hydroxyl value of 85, and an acid value of 10.0 and an oil degree of 45 was obtained.

Synthetic example 2

[0080] Add 616 parts of linseed oil, 299 parts of soybean oil fatty acid, 53 parts of p-tert-benzoic acid, 211 parts of pentaerythritol, 38 parts of dipropylene glycol, and 153 parts of glycerin into a flask with a stirring rod, a temperature sensor, a rectifying tube, and a decanter. parts, 563 parts of phthalic anhydride, 71 parts of xylene and 0.4 parts of organotitanium compound, blow dry nitrogen into the flask, and heat to 230-250°C while stirring to carry out dehydration condensation reaction. When the acid value reached 8.3 mgKOH / g, the reaction was stopped, and after cooling to 150° C., a mixed solvent (xylene / toluene=50 / 50 (mass ratio)) was added dropwise to dilute to a solid content of 60%. As a result, an alkyd resin (A2) having a number average molecular weight of 3,400, a mass average molecular weight of 90,000, a hydroxyl value of 108, and an oil degree of 8.3 with an acid value of 8.3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com