Air filter material as well as preparation method and application of air filter material

An air filtration material and substrate technology, applied in filtration and separation, separation methods, dispersed particle filtration, etc., can solve the problems of high resistance and high energy consumption, and achieve the effect of reducing resistance, stable growth process, and good purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

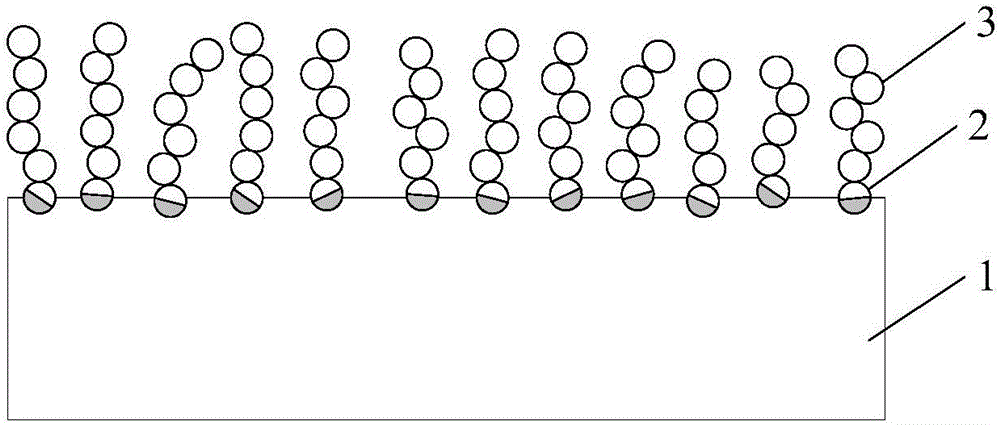

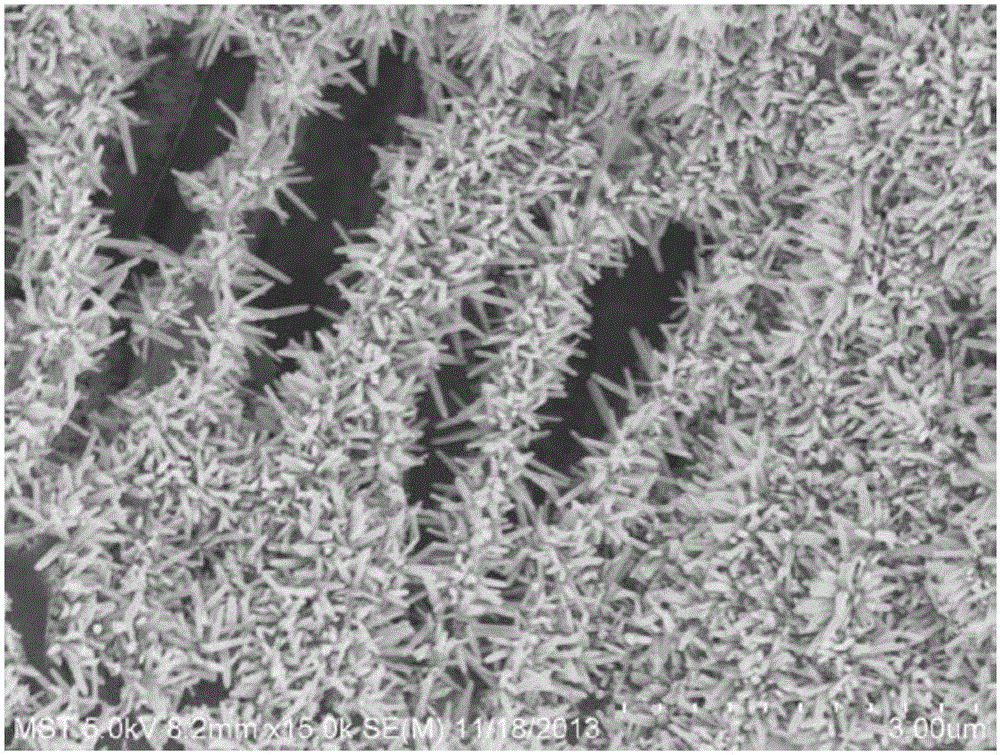

[0034] Prepare the air filter material, comprising the following steps:

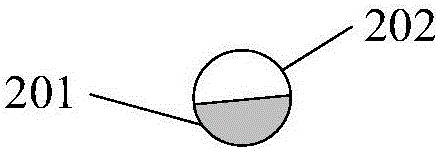

[0035] 1) Preparation of crystal nuclei: Surface treatment of nano tourmaline with a coupling agent to obtain a crystal nucleus composed of a hydrophilic hemisphere and an lipophilic hemisphere. The hydrophilic hemisphere is the part of the nano tourmaline whose surface has not been modified by a coupling agent. The oil hemisphere is a part of nano tourmaline whose surface is modified by a coupling agent, wherein the coupling agent is trimethoxysiloxane, and the particle size of the crystal nucleus is 50nm;

[0036] 2) Granulation: Blend the crystal nuclei obtained in step 1) with the polypropylene melt-blown special material and then melt-extrude and granulate to obtain intermediate particles doped with crystal nuclei; wherein, the melt-extrusion temperature of the intermediate particles is 200°C ; The weight of the crystal nucleus accounts for 0.5% of the total weight of the crystal nucleus and the pol...

Embodiment 2

[0041] Prepare the air filter material, comprising the following steps:

[0042] 1) Preparation of crystal nuclei: Surface treatment of nano tourmaline with a coupling agent to obtain a crystal nucleus composed of a hydrophilic hemisphere and an lipophilic hemisphere. The hydrophilic hemisphere is the part of the nano tourmaline whose surface has not been modified by a coupling agent. The oil hemisphere is a part of nano tourmaline whose surface is modified by a coupling agent; wherein, the coupling agent is a mixture of triethoxysiloxane and titanate coupling agent; the particle size of the crystal nucleus is 150nm;

[0043] 2) Granulation: blend the crystal nuclei obtained in step 1) with the polypropylene melt-blown special material, and then melt-extrude and granulate to obtain intermediate particles doped with crystal nuclei; wherein, the melt-extrusion temperature of the intermediate particles is 250°C ; The weight of the crystal nucleus accounts for 0.3% of the total we...

Embodiment 3

[0048] Prepare the air filter material, comprising the following steps:

[0049] 1) Preparation of crystal nuclei: Surface treatment of nano tourmaline with a coupling agent to obtain a crystal nucleus composed of a hydrophilic hemisphere and an lipophilic hemisphere. The hydrophilic hemisphere is the part of the nano tourmaline whose surface has not been modified by a coupling agent. The oil hemisphere is a part of nano tourmaline whose surface is modified by a coupling agent; wherein, the coupling agent is a titanate coupling agent, and the particle size of the crystal nucleus is 200nm;

[0050] 2) Granulation: Blend the crystal nuclei obtained in step 1) with the polypropylene melt-blown special material and then melt-extrude and granulate to obtain intermediate granules doped with crystal nuclei; wherein, the melt-extrusion temperature of the intermediate granules is 230°C ; The weight of the crystal nucleus accounts for 0.3% of the total weight of the crystal nucleus and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com