Maize crusher with continuous operation function

A continuous operation and pulverizer technology, applied in the field of continuous operation corn pulverizers, can solve the problems of inhumane design, high manual operation intensity, liberating productivity, etc., so as to improve the continuous working ability, reduce the trouble of disassembly, and reduce the internal temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

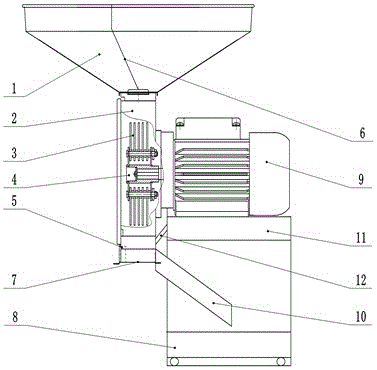

[0015] Such as figure 1 As shown, a continuous operation corn grinder is characterized in that it includes a frame, a cooling system arranged in the frame, an output motor 9 arranged on the frame, and one end of the output motor 9 is connected to the crushing machine through a rotating shaft 4 device; the inside of the frame is a hollow structure; the crushing device includes a crushing machine shell 2, a feed hopper 1 arranged on the crushing machine shell 2, a crushing hammer 3 arranged in the crushing machine shell 2, and a crushing hammer 3. The hoop is on the rotating shaft 4; the inside of the feed hopper 1 is divided into two compartments: a pre-feeding cabin and a feeding cabin; the pulverizer shell 2 is divided into an inner shell and an outer shell, A coolant channel is provided between the inner and outer casings, and the inner casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com