Self-lubrication impact crusher

An impact crusher, automatic lubrication technology, applied in the field of machinery and equipment, can solve the problems of reduced grease lubrication ability, accelerated bearing wear, increased noise, etc., to reduce equipment wear and noise, improve equipment life, and good lubrication performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the drawings and specific embodiments.

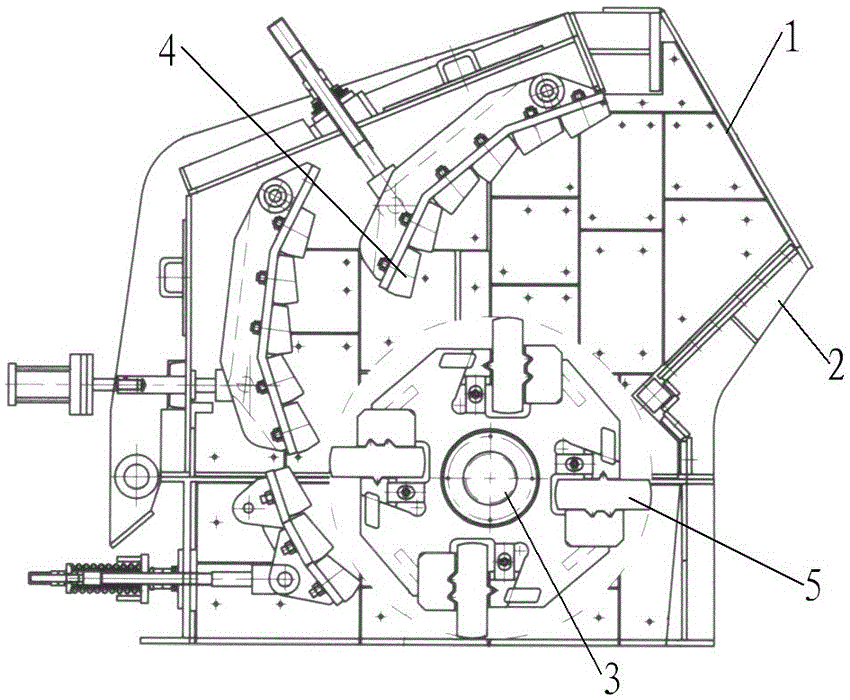

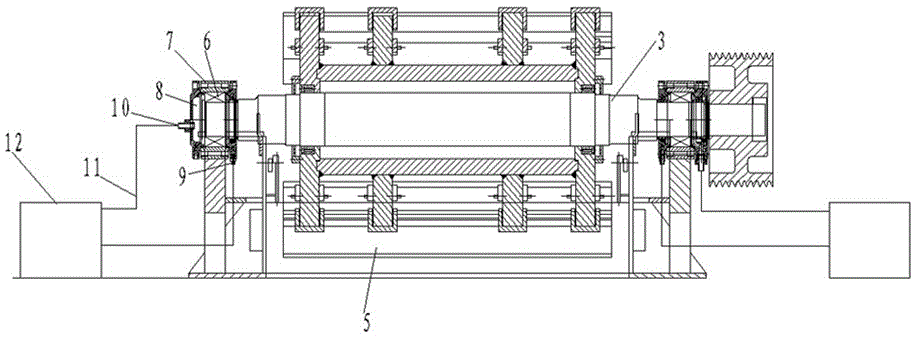

[0009] figure 1 , figure 2 Middle: feed inlet 1, machine casing 2, main shaft 3, counterattack device 4, blower 5, bearing 6, bearing seat 7, end cover 8, oil inlet 9, oil outlet 10, oil pipe 11, thin oil station 12.

[0010] The automatic lubrication type impact crusher includes a casing 2, a main shaft 3, and a counter-attack device 4 provided with a feed port 1. The main shaft 3 and the counter-attack device 4 are placed inside the casing 2, and the cylinder of the main shaft 3 A hammer 5 is fixedly connected to the surface. The two ends of the main shaft 3 and the side wall of the casing 2 are movably connected through a bearing 6, and a bearing seat 7 is connected to the outer ring of the bearing 6. The end of the bearing 6 is sealed by an end cover 8. The bearing 6 is placed in the lubrication space enclosed by the bearing seat 7 and the end cover 8. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com