C-shaped flange metal rubber component preparation technology method

A technology of metal rubber and preparation process, which is applied in metal processing equipment, manufacturing tools, forming tools, etc., to achieve the effect of ensuring consistency, good size and performance consistency, and good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

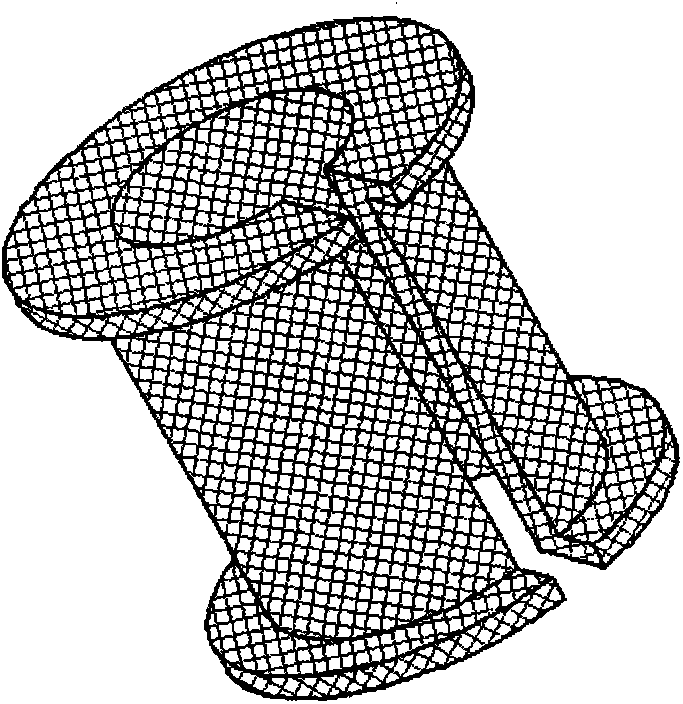

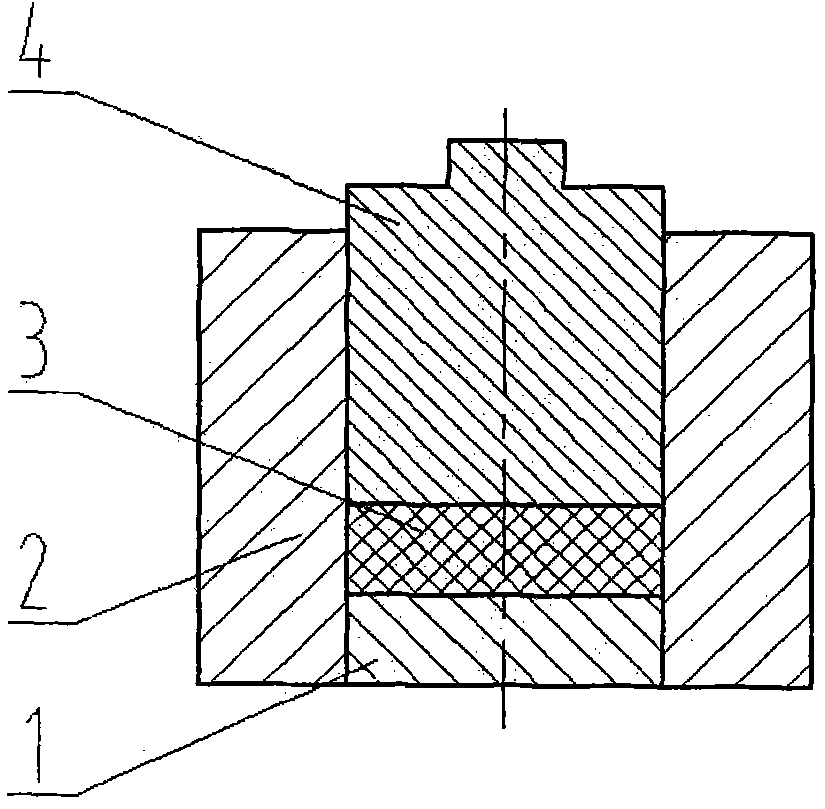

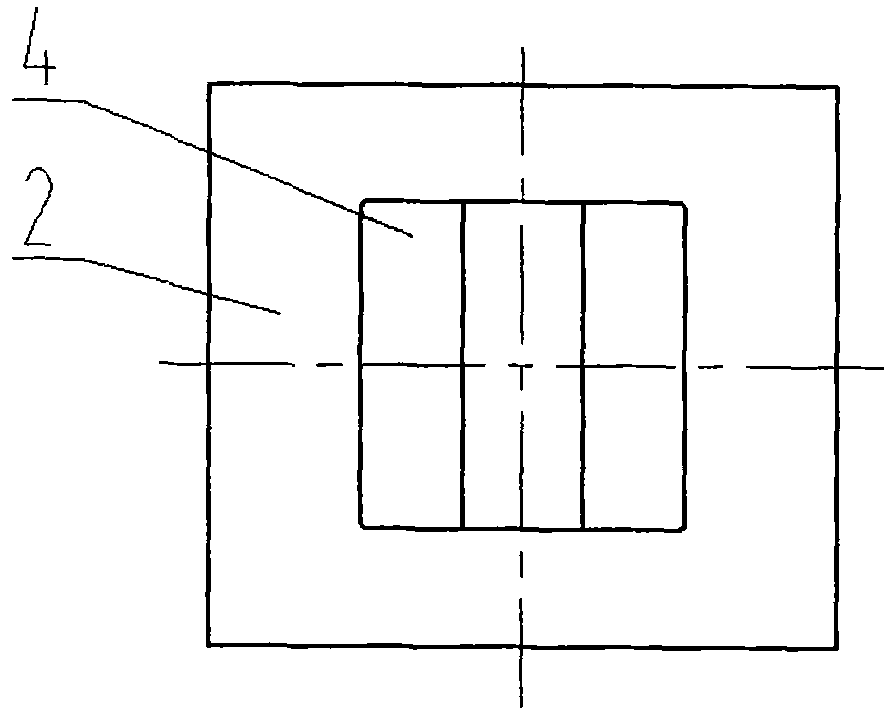

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] The preparation process of the C-shaped flanging metal rubber component includes the following steps:

[0030] The first step is to select the metal wire and wind it into a dense spiral coil with a special winding machine;

[0031] According to the technical index requirements of the prepared metal rubber components, select the material and diameter of the metal wire, the diameter range is 0.10~0.30mm, in the special winding machine (see the utility model patent "wire winding machine", the patent number is ZL201320258105.8, The publication date is December 25, 2013). The metal wire is wound into a dense spiral coil. The diameter of the spiral coil is controlled to be 5-15 times the diameter of the metal wire to ensure that the inner spiral coil of the metal rubber component is formed between the turns Good connection.

[0032] The second step is to prepare th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com