Anti-overflowing continuous-casting tundish

A continuous casting tundish and tundish technology, which is used in foundry equipment, casting melt containers, metal processing equipment, etc., can solve problems such as safety accidents, molten steel overflow, and many tundishes, so as to reduce safety accidents and reduce heat loss. , to avoid the effect of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

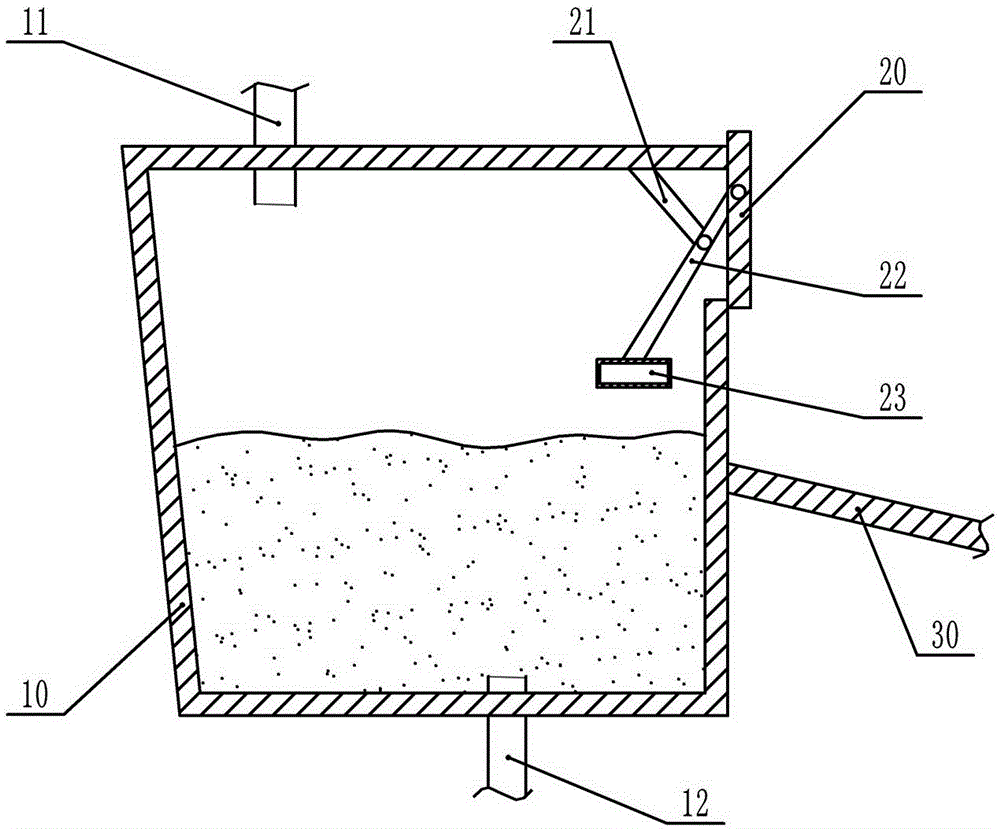

[0013] The reference signs in the drawings of the description include: tundish body 10 , liquid inlet 11 , liquid outlet 12 , baffle 20 , strut 21 , rotating rod 22 , floating block 23 , and slide 30 .

[0014] Such as figure 1 As shown, the continuous casting tundish capable of preventing overflow includes a tundish body 10 , a baffle plate 20 , a rotating rod 22 , a floating block 23 , a support rod 21 and a slide 30 . The top of the tundish body 10 is processed with a liquid inlet 11 , and the bottom is processed with a liquid outlet 12 . In addition, an overflow port is provided on the side wall of the tundish body. The pole 21 is welded on the inner wall of the tundish body 10, the rotating rod 22 is hinged on the pole 21 through a high temperature resistant pin, the baffle plate 20 is hinged on the upper end of the rotating rod 22 through a high temperature resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com