Crane box girder three-degree-of-freedom movable welding robot

A welding robot and crane technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of high welding labor intensity and unstable manual welding quality, so as to improve welding efficiency, reduce labor intensity of workers, and achieve high orientation. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

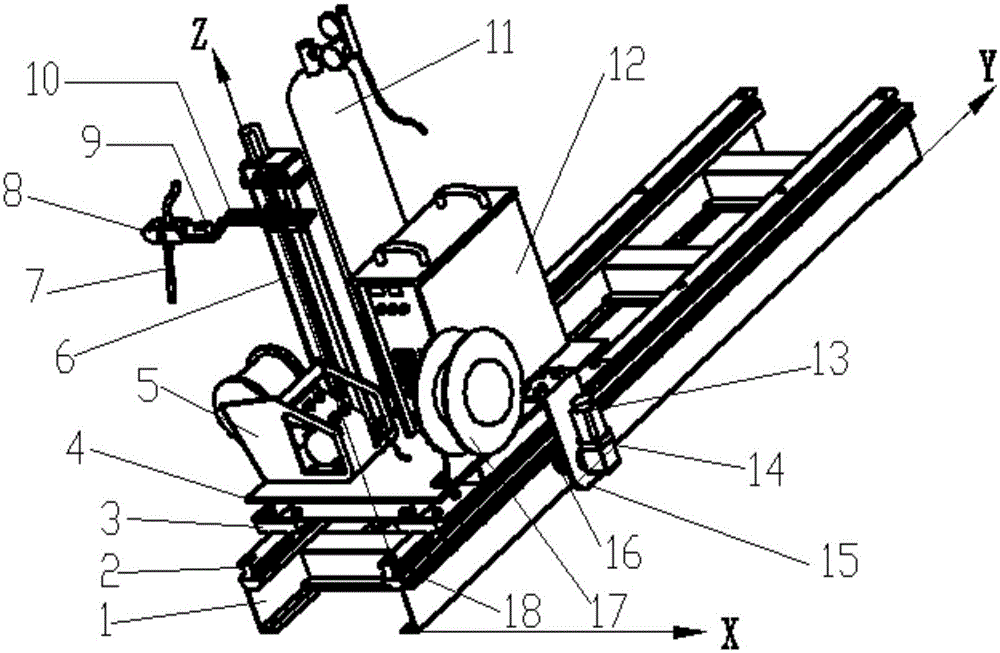

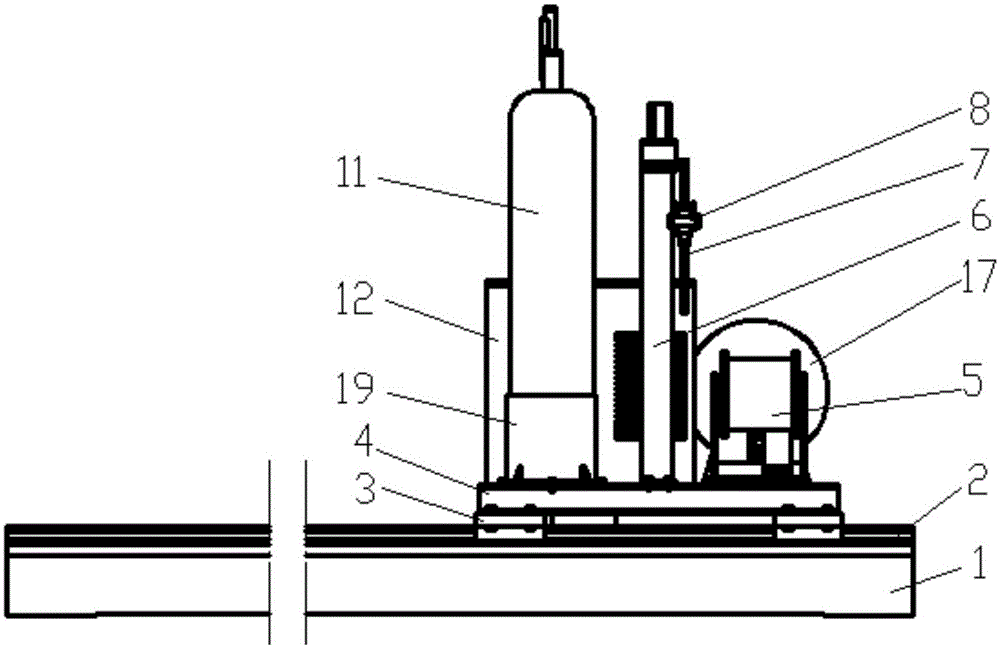

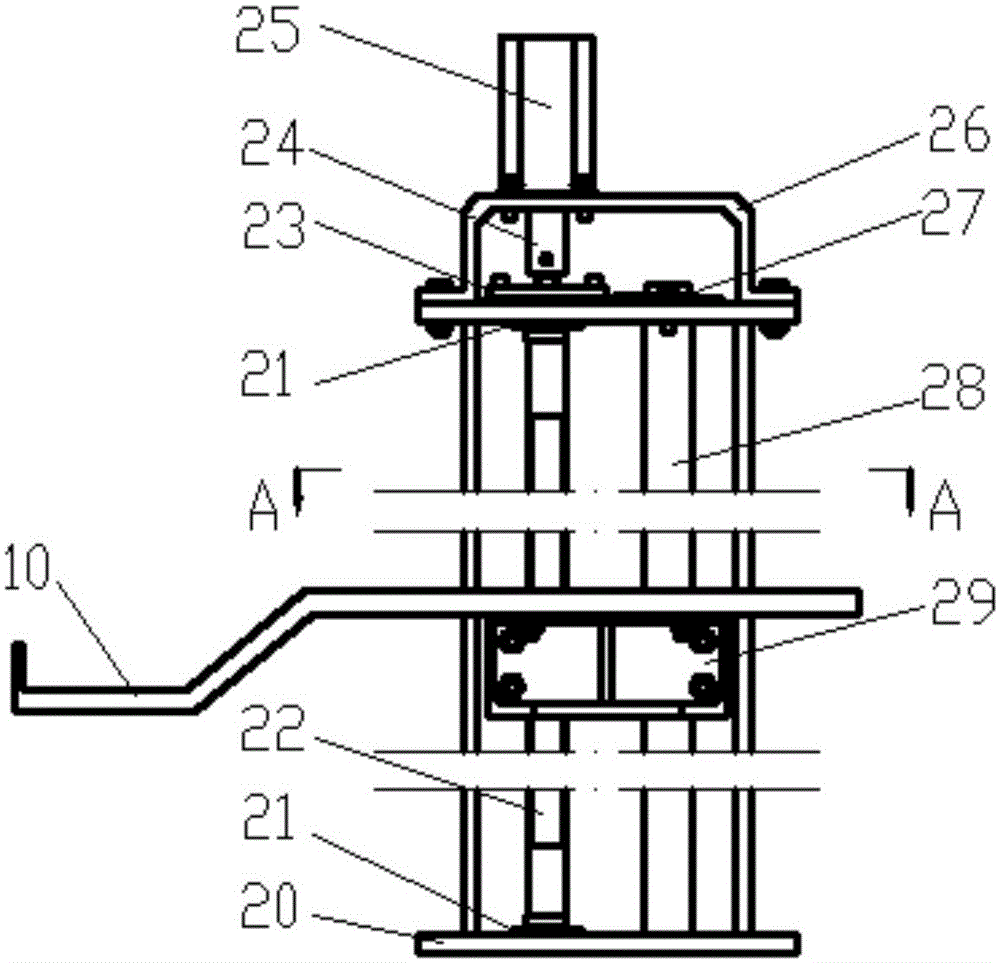

[0011] See figure 1 , 2 , a crane box-shaped main girder three-degree-of-freedom mobile welding robot, including a base 1, a longitudinal movement mechanism, a welding torch lifting mechanism 6, a welding torch rotation mechanism, welding equipment and a cable reel 17. Described base 1 is made up of channel steel, steel plate and I-beam welding, and its longitudinal direction ( figure 1 The length in the middle Y direction) is greater than the maximum length of the crane box-shaped girder to be welded, and the linear guide rail 2 is fixed on the base 1 by bolts along the length direction of the base. Require.

[0012] The longitudinal movement mechanism includes a roller slider 3, a mobile frame 4, a second servo motor 13, a reducer 14, an L-shaped plate 15, a gear 16, and a rack 18, and the mobile frame 4 and the roller slider 3 pass through The bolts are rigidly connected, the roller slider 3 is set on the linear guide rail 2, the rack 18 is fixed on the side of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com