Damping device for a spindle of a grinding machine and grinding machine comprising a damping device

A buffer device and grinding machine technology, which is applied to the parts of grinding machine tools, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve problems such as the optimization of vibration characteristics of grinding machines, and achieve Improved reproducibility, improved process stability, and load reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

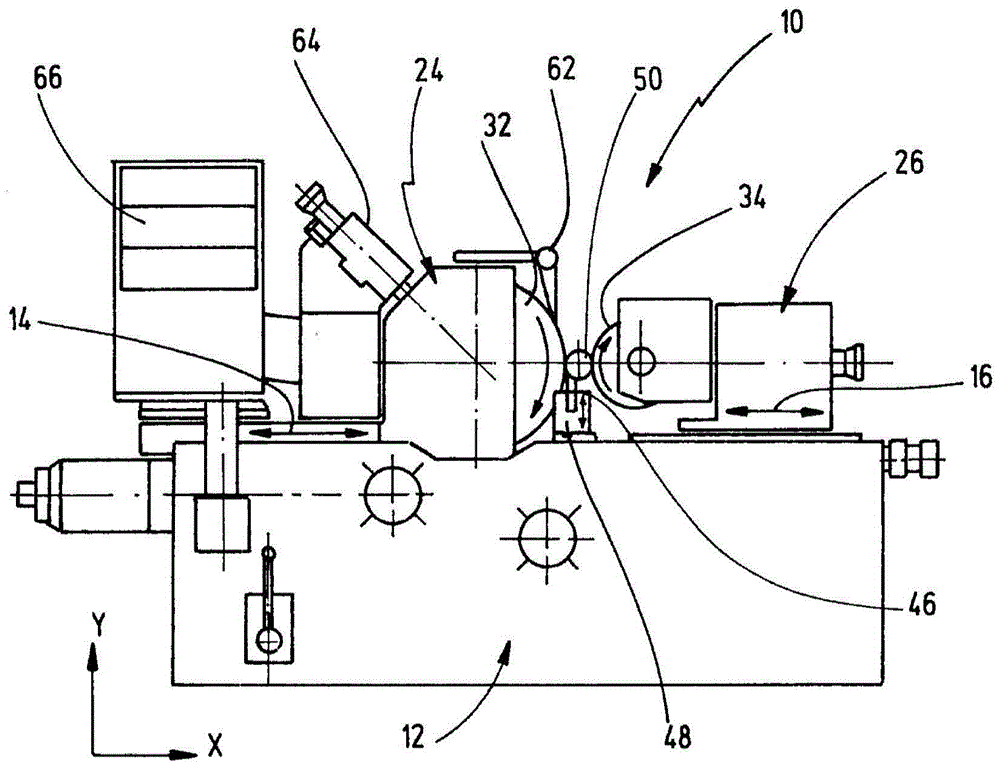

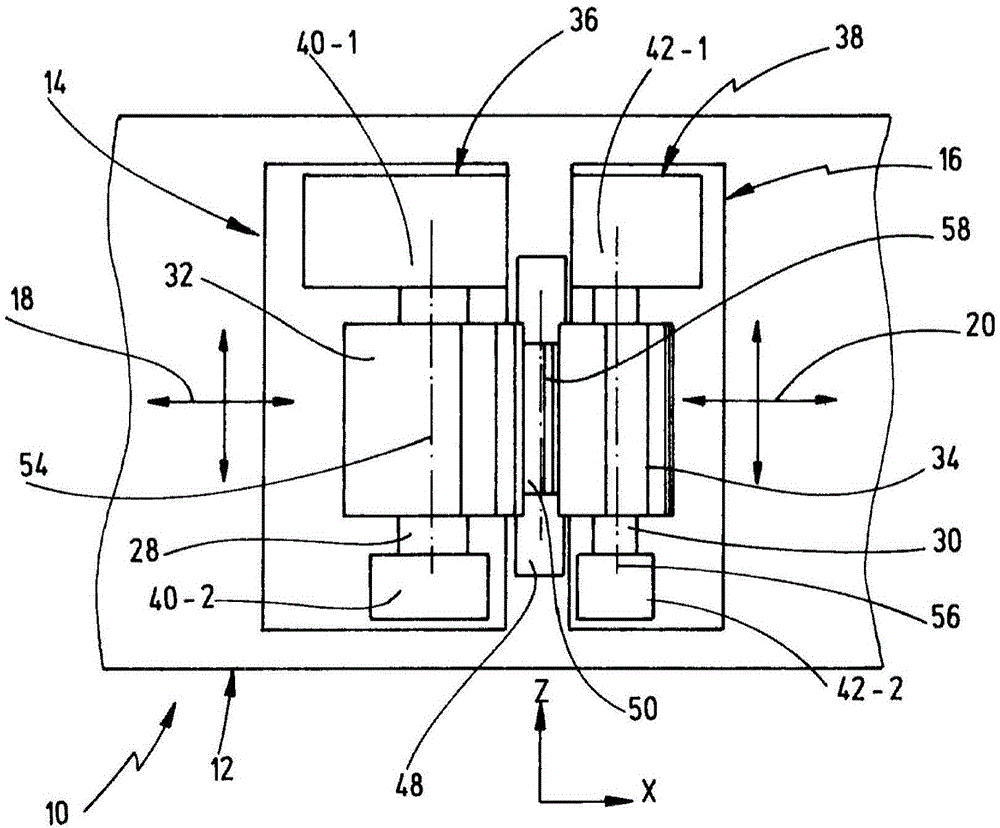

[0060] figure 1 The figure shows a front view of the grinding machine, designated 10 . refer to figure 1 and supplementary references figure 2 (exist figure 2 , a schematic and greatly simplified partial view of the grinding machine 10 is shown in plan view), the principle construction and main components of the grinding machine 10 are described below.

[0061] The grinding machine 10 can in particular be designed as a so-called headless grinding machine 10 . For example by means of figure 1 with figure 2 The grinding machine shown in the figure is configured as a topless cylindrical grinding machine. The grinding machine 10 has a machine tool 12 which can also be referred to as a machine frame. Carriage guides 14 , 16 , which enable the travel movement of the components of the grinding machine 10 , can be accommodated on the machine tool 12 .

[0062] exist figure 1 with figure 2 In the overview, a coordinate system X-Y-Z is available which can be used to plot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com