Technology for improving compression performance of composite material laminated board

A composite material layer and pressing board technology, which is applied in the field of composite material laminate preparation, can solve the problems of different resin content and different glue absorption, and achieve the effect of increasing compression performance and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

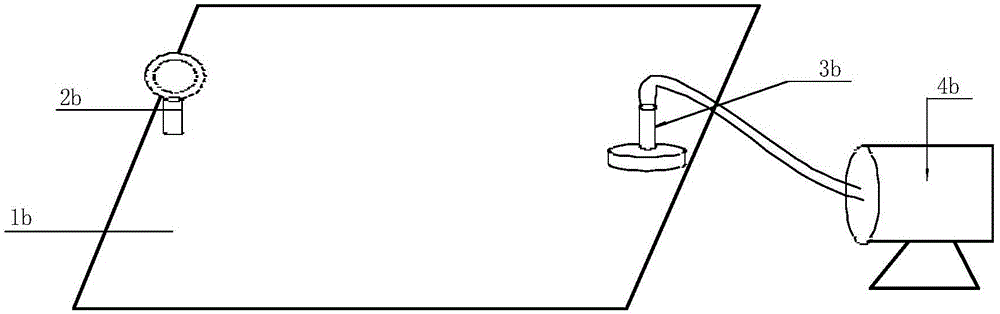

Embodiment 1

[0028] Such as figure 2 , lay 6 prepreg laminates on a flat glass mold of 1200mm×2500mm, the size is 300mm×300mm, after laying, a layer of release cloth is placed on top of the prepreg blank, and three layers of absorbent Adhesive plaster, one layer of non-porous isolation film, one layer of air felt, one layer of vacuum bag, seal the vacuum bag with yellow sealant, the air felt should completely cover the isolation film, the vacuum bag should completely cover the air felt, and the vacuum pump 4b passes through the vacuum joint 3b is connected to the vacuum bag 1b. At this time, turn on the vacuum pump 4b and pump the vacuum. It can be observed through the vacuum gauge 2b that the actual vacuum degree is -0.97MPa. After the laying is completed, the laminate is cured. The thickness of the cured board was tested, and it was found that the thickness of the glue-absorbed laminate was 3.3% thinner than that of the non-absorbed laminate, and the compressive strength increased by 7....

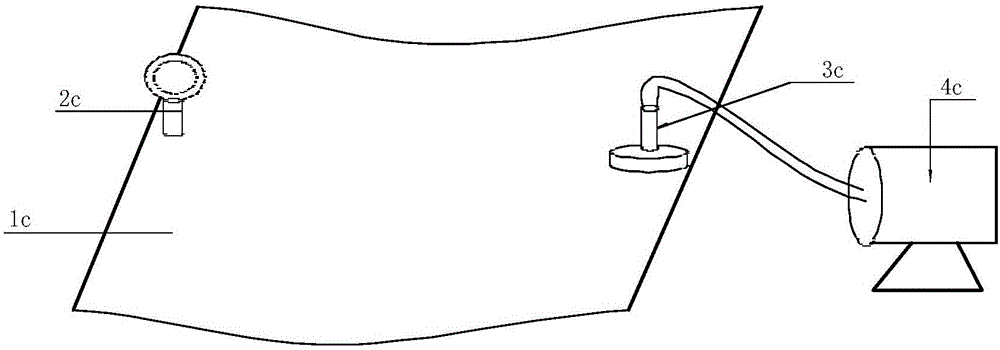

Embodiment 2

[0030] Parts with more complex structures are selected for testing. The selected mold has a larger curvature, and then place the auxiliary materials and the same quantity and specification of the suction cloth in the same order as in Implementation 1, such as image 3 As shown, the vacuum pump 4c is connected to the vacuum bag 1c through the vacuum connector 3c. At this time, turn on the vacuum pump 4c and pump the vacuum. It can be observed through the vacuum gauge 2c that the actual vacuum degree is -0.97MPa. After the laying is completed, the laminate is cured . The thickness of the cured board was tested, and it was found that the thickness of the glue-absorbed laminate was 3.75% thinner than that of the non-absorbed laminate, and the compressive strength increased by 8.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com