Surface photocatalytic modification method for water treatment inorganic membrane

An inorganic membrane and photocatalytic technology, which is applied in the direction of light water/sewage treatment, etc., can solve the problems of no photocatalytic performance, easy clogging of membrane pores, and influence of membrane pollution, so as to improve the ability to resist membrane pollution, improve effluent water quality, and improve The effect of hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

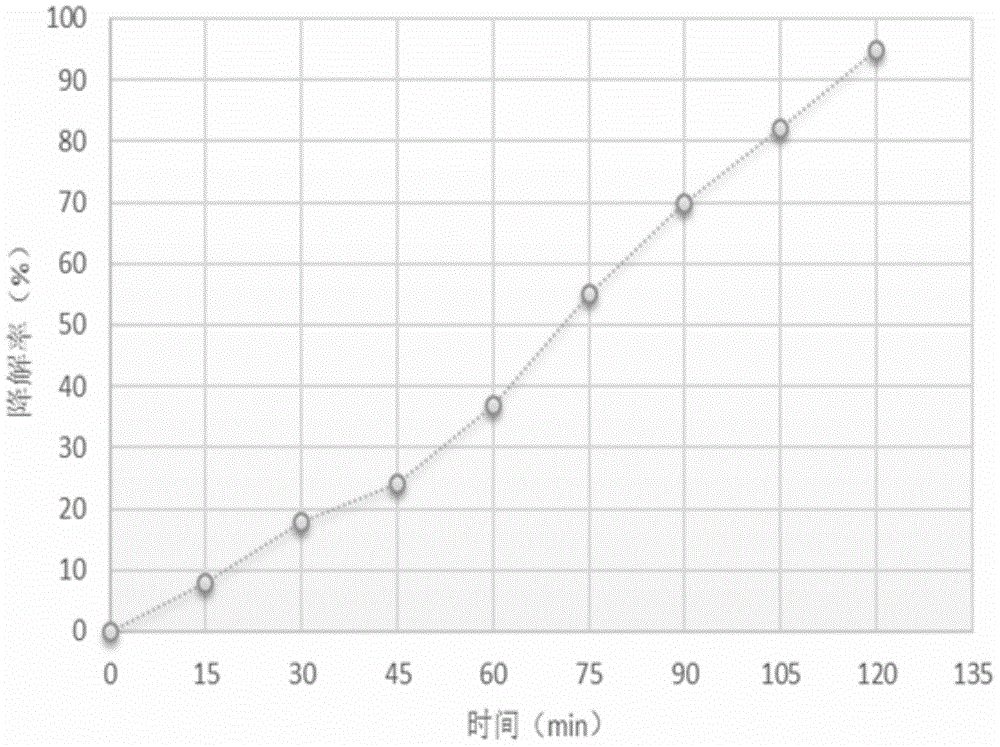

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: the method for surface photocatalytic modification of water treatment inorganic membrane in this embodiment is realized according to the following steps:

[0017] 1. Put the inorganic film in the reaction chamber of the atomic layer deposition device, heat the inorganic film and the reaction chamber cavity, and obtain the pretreated inorganic film;

[0018] 2. On the surface of the pretreated inorganic film, Ti source deposition, O source deposition, Ti source deposition, N source doping deposition, Zn source deposition, O source deposition, Zn source deposition and N source doping are carried out in sequence for polyatomic Deposition of the layer, during the deposition process, nitrogen is used as the reaction carrier gas and the purge gas of the excess reaction source to obtain a photocatalytically modified inorganic film for water treatment;

[0019] Wherein the Ti source described in step 2 is selected from TiCl 4 、Ti(OCH(CH 3 ) 2 ) 4 , ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that step 1 heats the inorganic membrane and the reaction chamber to 150-350°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the inorganic membrane described in step 1 is a ceramic membrane, a metal membrane or a metal alloy membrane. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com