Method for preparing anti-pollution flashover insulators

An anti-pollution flashover technology for insulators, applied to insulators, electrical components, circuits, etc., can solve the problems of frequent pollution flashover accidents of insulators, and achieve the goals of preventing pollution flashover accidents, good photocatalytic self-cleaning performance, and preventing pollution flashover events Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mix metatitanic acid and deionized water at a concentration of 0.1mol / L and stir for 15 minutes to obtain a mixed solution; slowly add hydrogen peroxide to the above mixed solution at a molar ratio of titanium ions: hydrogen peroxide = 1:1 at 25°C , to obtain the sol precursor solution, the above sol precursor solution according to the titanium ion: SiO 2 Sol (SiO 2 content is 20wt%) and mixed at a mass ratio of 1:1 and stirred evenly to obtain a composite sol; add vanadium oxalate to the above sol at an atomic percentage of 5%, stir and dissolve, and spray on the just-prepared porcelain Coating film on the surface of the insulator; the final loaded film is dried at 120°C for 30 minutes, and then heat-treated at 350°C to obtain an anti-fouling flashover insulator with good adhesion to the substrate. figure 1 The FESEM picture of the surface of the sample prepared in Example 1 shows that the film layer is very uniform, consisting of titanium oxide particles with a size ...

Embodiment 2

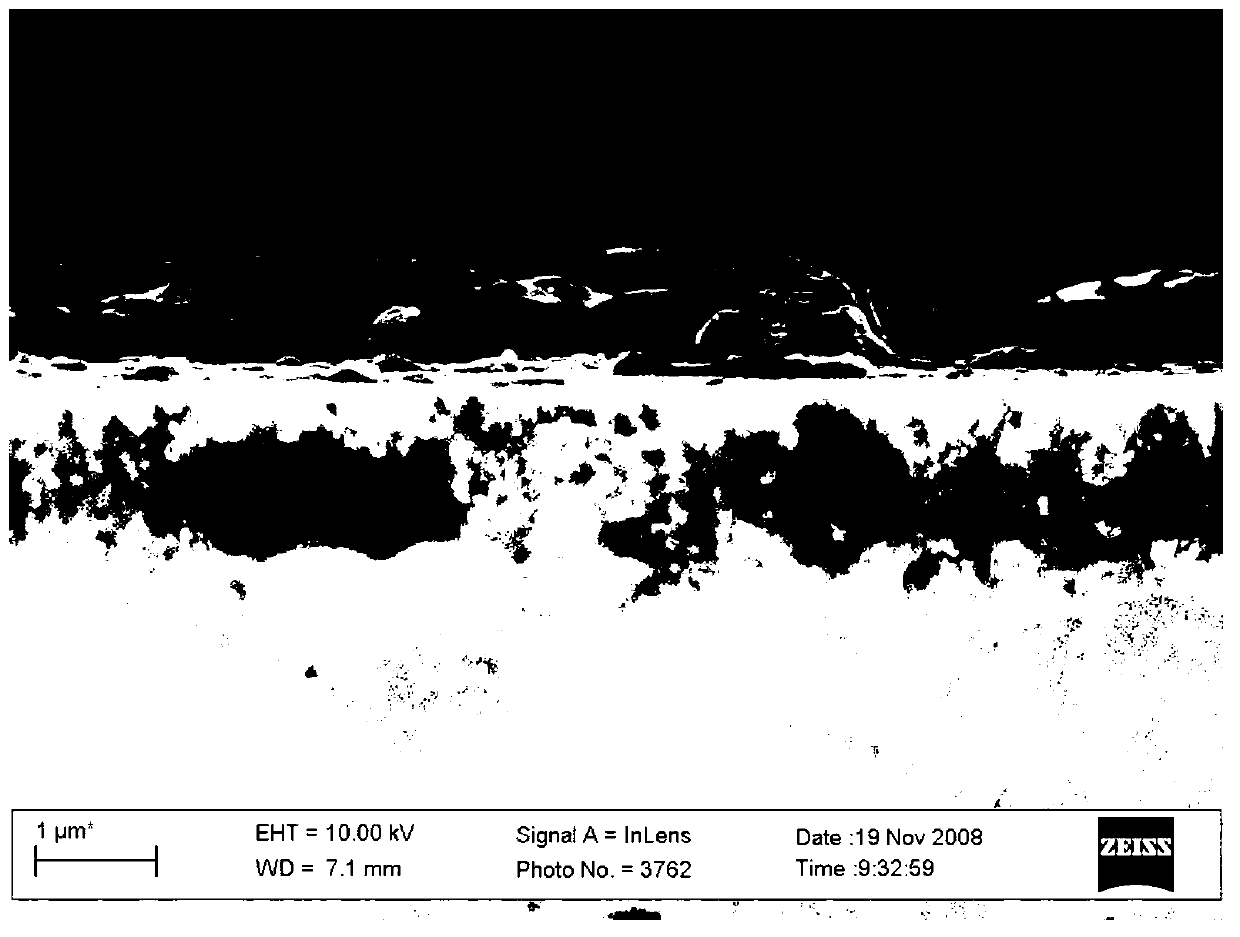

[0021] Mix metatitanic acid and deionized water at a concentration of 2mol / L and stir for 90 minutes to obtain a mixed solution; slowly add hydrogen peroxide to the above mixed solution at a molar ratio of titanium ions: hydrogen peroxide = 1:5 at 40°C, After stirring for 3 hours, the sol precursor solution was obtained, and the above sol precursor solution was prepared according to the titanium ion: SiO 2 Sol (SiO 2 content is 40wt%) and the mass ratio is 0.5:1, mixed and stirred evenly to obtain a composite sol; add vanadium citrate to the above sol at an atomic percentage of 0.1%, stir and dissolve to obtain a doped coating film precursor , using the dip coating process to coat the surface of the just prepared porcelain insulator, the insulator sample after coating was dried at 140°C for 20 minutes, and after heat treatment at 600°C, the anti-pollution flashover insulator with good adhesion to the substrate was obtained. figure 2 For: the FESEM picture of the section of t...

Embodiment 3

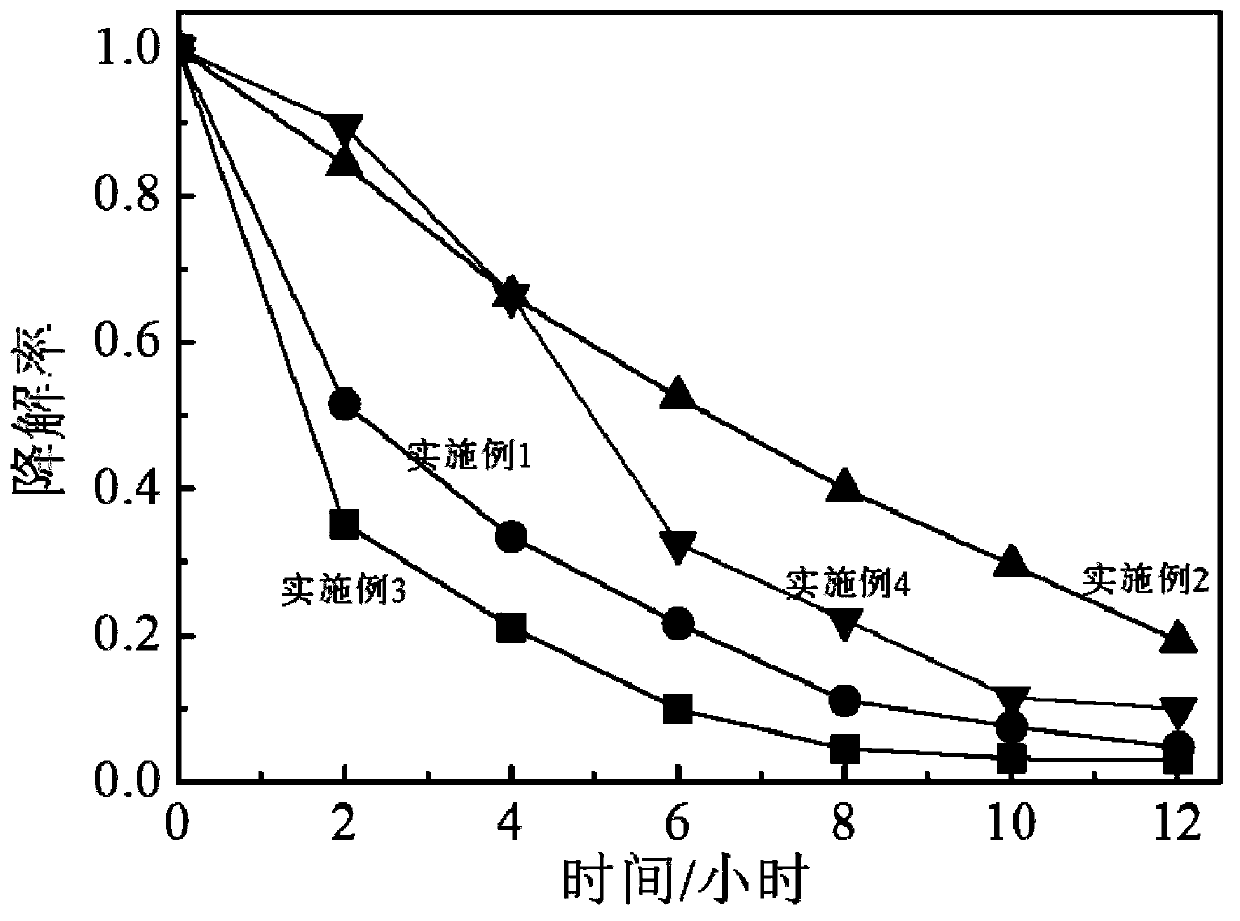

[0023] Mix metatitanic acid and deionized water at a concentration of 0.5mol / L and stir for 30 minutes to obtain a mixed solution; slowly add hydrogen peroxide to the above mixed solution at a molar ratio of titanium ions: hydrogen peroxide = 1:10 at 60°C , and then stirred for 0.5h to obtain the sol precursor solution, the above sol precursor solution according to the titanium ion: SiO 2 Sol (SiO 2 The content is 5wt%) and the mass ratio is 5:1. After mixing, stir evenly to obtain a composite sol; add vanadium acetate to the above sol in an amount of 1% atomic percentage, stir and dissolve, and obtain a doped coating film precursor. Use the dip coating process to coat the surface of the just-prepared porcelain insulator. After the coated insulator sample is dried at 120°C for 60 minutes, it is heat-treated at 550°C to obtain an anti-fouling flashover insulator with good adhesion to the substrate. image 3 It is: a schematic diagram of the degradation data of 200ml of methyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com