Ceramic sintering antisticking coating, preparation method and application

A technology of anti-sticking coating and ceramics, which is applied in the field of ceramics, can solve the problems of low anti-sticking persistence of anti-sticking coatings, dusty and dirty ceramic parts, and affecting product quality. The effect of product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

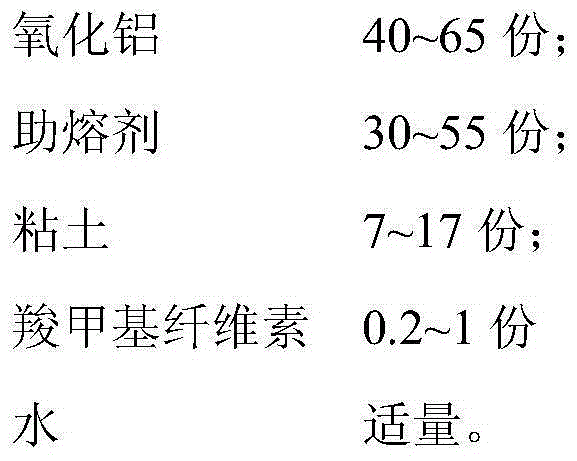

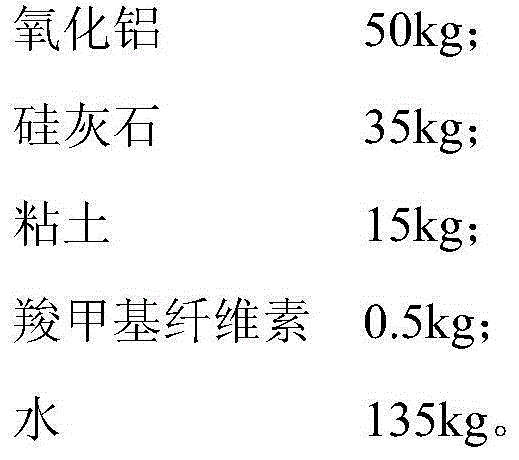

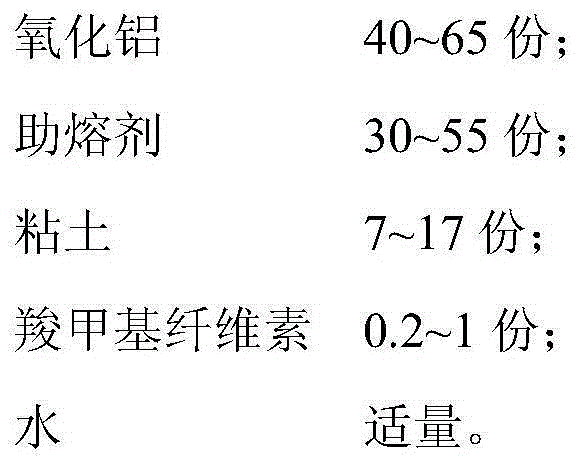

[0027] A kind of prescription of ceramic firing anti-stick coating, table 1:

[0028] Table 1 Coating formula (kg)

[0029]

[0030] Wherein, the flux is one or a combination of wollastonite and talc. Wollastonite and talc have a low coefficient of expansion and are more effective in fluxing when added.

Embodiment 6

[0032] A preparation method for ceramic firing anti-stick coating, comprising the following steps:

[0033] (1) prepare raw materials according to the formula described in embodiment 1-5;

[0034] (2) Add alumina, flux, clay and water to a ball mill, and ball mill to a 325 mesh sieve with 0.2% to 1.0% remaining;

[0035] (3) Add carboxymethyl cellulose and ball mill for 30 minutes to obtain coating 1-5.

[0036] In step (1), preferably ball milling to 325 mesh sieve remaining 0.4%.

[0037] The prepared coating 1-5 has a specific gravity of 1.45-1.70 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com