Polystyrene dipropyl maleate, preparation method and application thereof

A technology of polystyrene dipropyl butenedioate and dipropyl butenedioate is applied in the field of polystyrene dipropyl butenedioate and its preparation, and can solve the problem of large dosage, unsuitable for oil production, There are few types of tracers, etc., to achieve the effect of low dosage and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

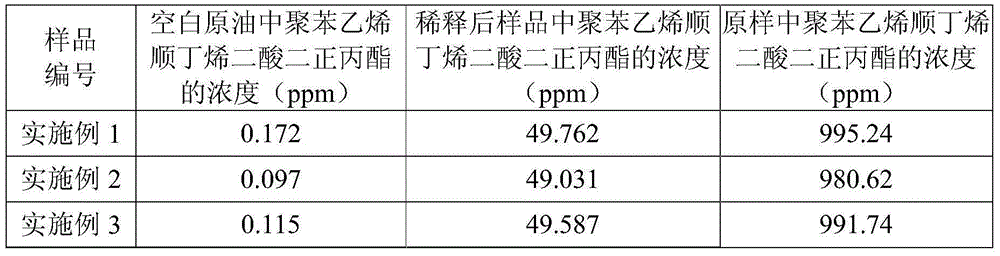

Embodiment 1

[0031] The present embodiment provides a kind of preparation method of polystyrene di-n-propyl maleate, it comprises the following steps:

[0032] a. Dissolve 0.1 g of polyethylene glycol (PEG4000) in 55 g of hot water, raise the temperature to 65° C. and keep the temperature for 30 minutes to obtain an aqueous solution of polyethylene glycol;

[0033] b. Slowly add a mixed solution of 40g di-n-propyl maleate, 4g styrene and 0.9g azobisisobutyronitrile dropwise to the aqueous solution of polyethylene glycol at a rate of 5-10 drops / min , react for 10 hours after the dropwise addition, cool to room temperature and discharge to obtain polystyrene di-n-propyl maleate with a particle size of 0.300mm-0.850mm (20 mesh-50 mesh).

Embodiment 2

[0035] The present embodiment provides a kind of preparation method of polystyrene di-n-propyl maleate, it comprises the following steps:

[0036] a. Dissolve 0.15g of polyethylene glycol (PEG4000) into 60g of hot water, raise the temperature to 65°C and keep the temperature for 30min to obtain an aqueous solution of polyethylene glycol;

[0037] b. Add a mixed solution of 35g di-n-propyl maleate, 3.5g styrene and 0.8g azobisisobutyronitrile dropwise to the aqueous solution of polyethylene glycol at a rate of 5-10 drops / min , reacted for 10 hours after the dropwise addition was completed, cooled to room temperature and discharged to obtain polystyrene di-n-propyl maleate with a particle size of 0.212mm-0.425mm (40 mesh-70 mesh).

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of polystyrene di-n-propyl maleate, it comprises the following steps:

[0040] a. Dissolve 0.2g of polyethylene glycol (PEG4000) in 65g of hot water, raise the temperature to 65°C for 30 minutes, and obtain an aqueous solution of polyethylene glycol;

[0041] b. Add dropwise a mixed solution of 30g di-n-propyl maleate, 3g styrene and 0.6g azobisisobutyronitrile to the aqueous solution of polyethylene glycol at a rate of 5-10 drops / min, After the dropwise addition, react for 10 hours, cool to room temperature and discharge to obtain polystyrene di-n-propyl maleate with a particle size of 0.180mm-0.300mm (50 mesh-80 mesh).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com