Method for producing flexible finish material

A production method and flexible facing technology, applied in the production field of flexible facing materials, can solve the problems of restricting the use of natural stone and imitation stone materials, the ability to achieve effects, and the single effect of classic stone shapes, etc., to achieve high artistic appreciation High performance, easy access to materials, and good decorative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1 imitates Spanish beige travertine

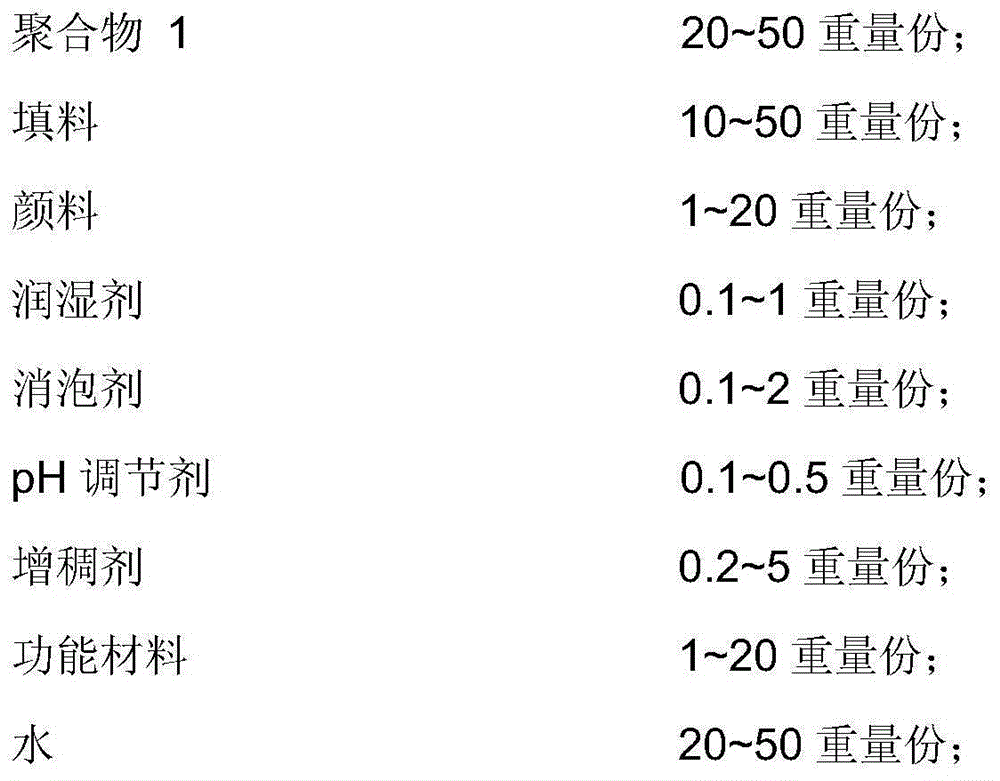

[0050] First of all, according to the needs of the market and customers, use natural or pre-processed Spanish travertine models to remake molds, prepare travertine molds with an inner cavity of 400mm*800mm*3mm, and trim and cut individual large hole columns to ensure the overall The maximum thickness shall not exceed 4mm; prepare a surface color paste and a base color paste at the same time, and the surface color paste components include:

[0051] The transparent diluent is: pure water

[0052] The composition weight ratio of face color slurry is:

[0053]

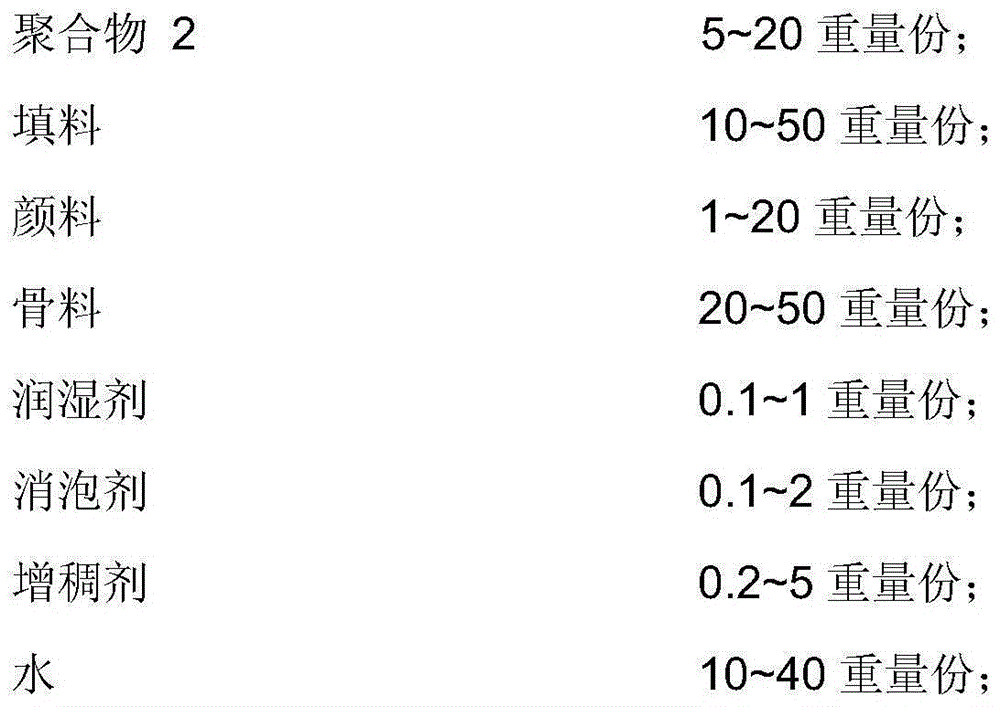

[0054] The weight ratio of the base color slurry component corresponding thereto is:

[0055]

[0056] Using water as the face color diluent, prepare the face color paste with a viscosity of 60ku and the base color paste with a fluidity of 210mm, pass through the corresponding equipment, pay attention to spraying in order, and then scrape on the silicone mold ...

Embodiment 2

[0060] Embodiment 2 antique brick (red brick)

[0061] First, use natural or pre-processed antique brick models to remake molds according to the needs of the market and customers. The size of the mold is 60mm*220mm*3mm, and the single module is combined into an overall size of 700mm*700mm, and the distance between the single modules is 2mm; at the same time, three kinds of surface color pastes and one base color paste are prepared. The surface color paste components include:

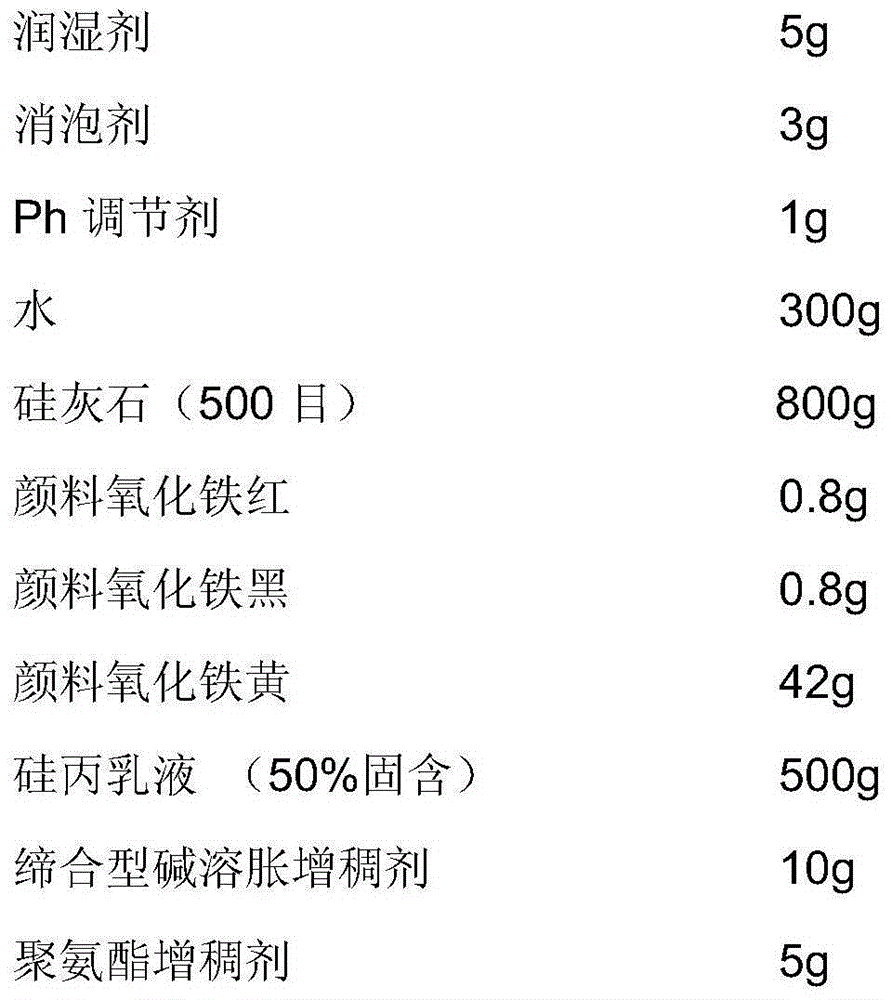

[0062] The weight ratio of face color slurry 1 component is:

[0063]

[0064] The weight ratio of the face color paste 2 components is:

[0065]

[0066]

[0067] The weight ratio of the 3 components of the complexion paste is:

[0068]

[0069] The weight ratio of the base color slurry component corresponding thereto is:

[0070]

[0071] Prepare three kinds of surface color slurry with a viscosity of 65ku and a base color slurry with a fluidity of 190mm, pass corresponding equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com