A kind of smt strip cutting device and cutting and labeling method

A technology of shearing device and material belt, applied in metal processing and other directions, can solve problems such as low compatibility, eye fatigue, labor occupation, etc., and achieve the effect of improving the degree of automation, wide range of sizes and types, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

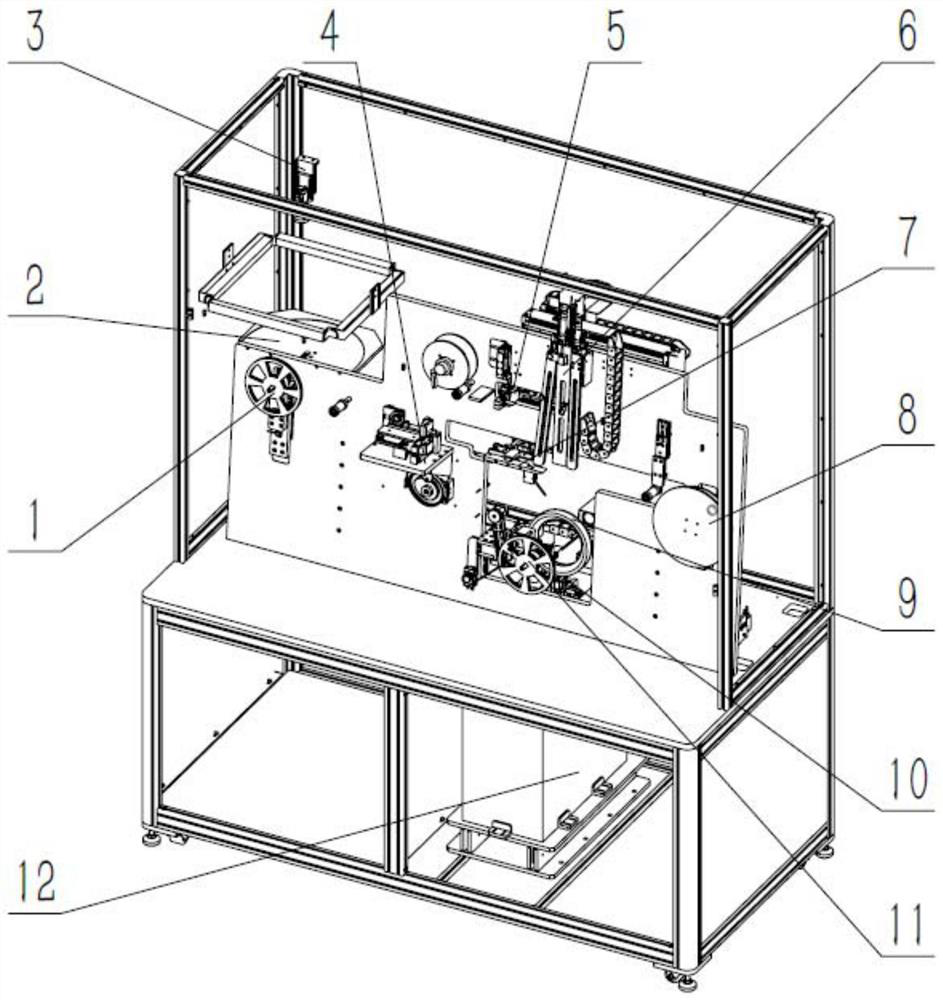

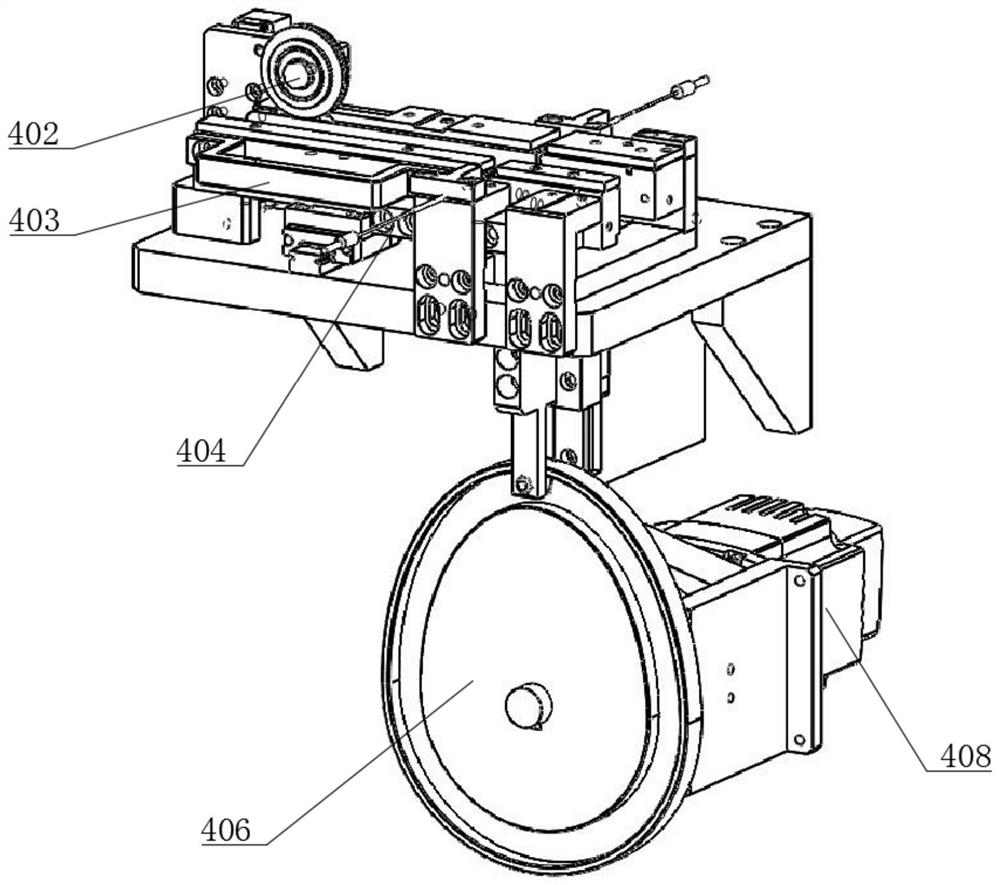

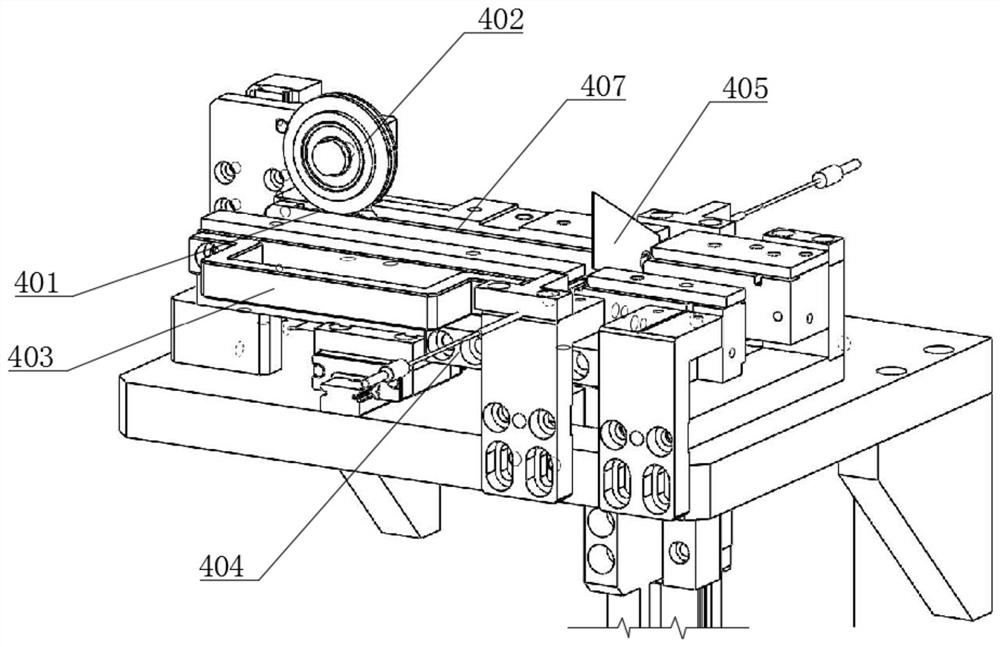

[0042] Such as figure 1 Shown, a kind of SMT strip shearing device, comprises frame and is arranged on the loading code reading mechanism 2 on described frame, strip point number cutting mechanism 4, tape cutting mechanism 5, tape pasting mechanism 6, Tape grabbing mechanism 7 , intermediate turntable 8 , receiving tray 11 , and unloading code reading mechanism 9 , barcode printing mechanism 12 and labeling mechanism 10 located near the receiving tray 11 .

[0043] The material loading and code reading mechanism 2 is loaded with a raw material tray 1, and the SMT material tape to be cut is wound on the raw material tray 1, and the material loading and code reading mechanism 2 is located above the raw material tray 1 to read the The bar code of the cut material tape is connected with the control system, and the bar code information is transmitted to the control system to confirm the quantity of the material tape to be cut. The loading code reading mechanism 2 includes a loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com