Sapphire drilling liquid

A technology of liquid diamond and sapphire, which is applied in the field of liquid diamond grinding, can solve the problems of low grinding rate of A-direction sapphire, and achieve the effect of facilitating product cleaning and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

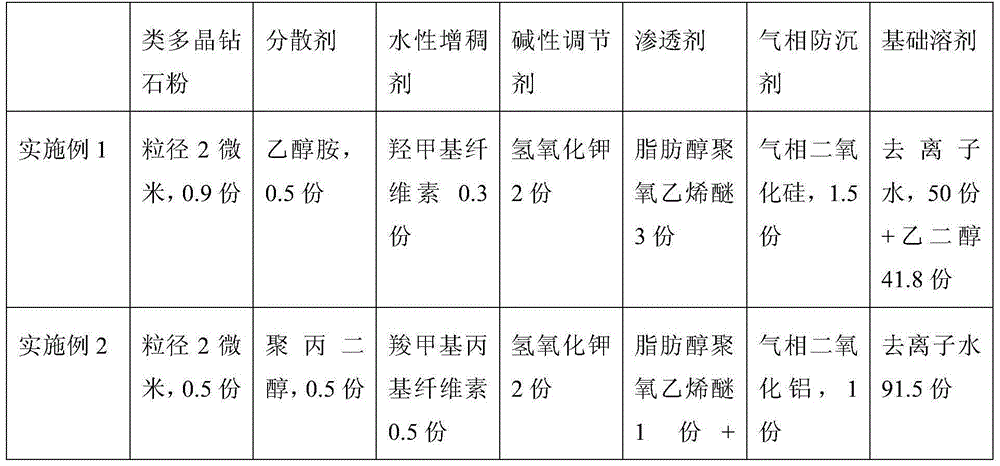

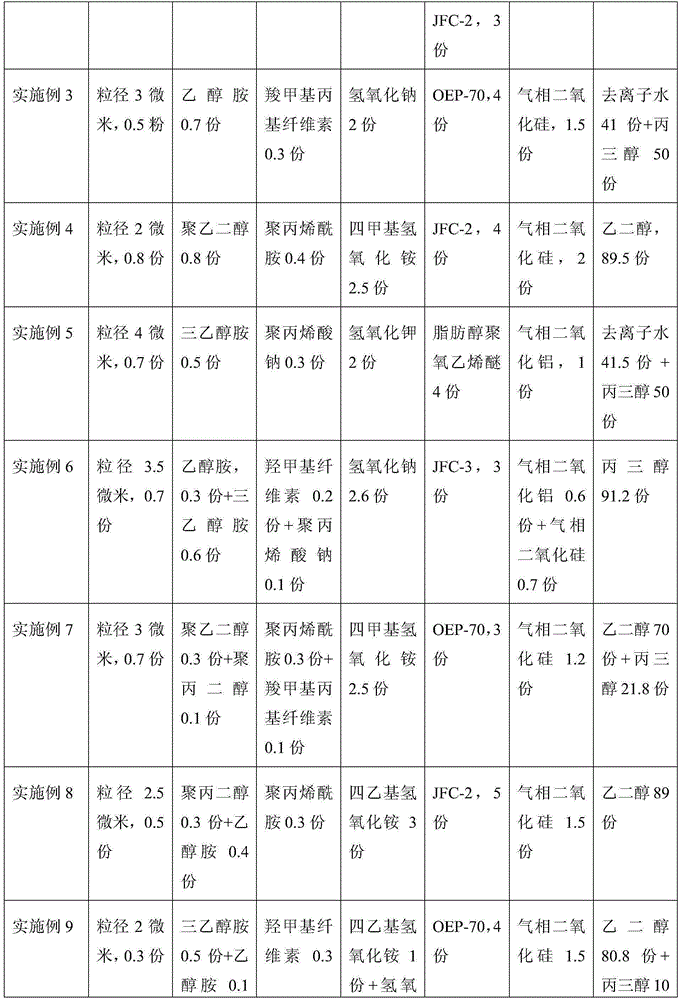

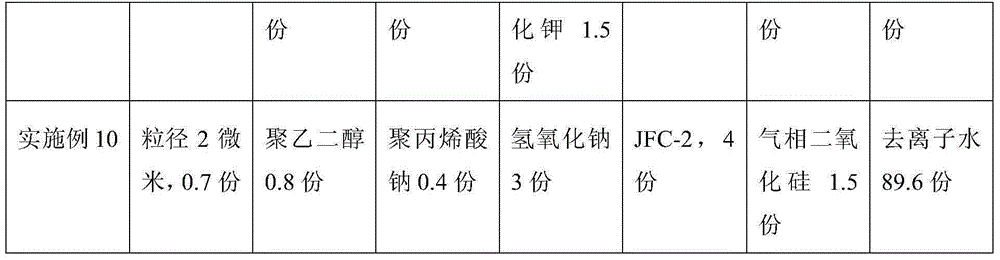

[0019] A sapphire diamond liquid, comprising 0.5-1.0 parts of polycrystalline diamond powder, 0.5-1.0 parts of dispersant, 0.1-0.5 parts of water-based thickener, 2-4 parts of alkaline regulator, 3-5 parts of penetrating agent, 1 -2 parts of vapor phase anti-settling agent, 86.5-92 parts of base solvent;

[0020] The base solvent is prepared by mixing one or more of deionized water, ethylene glycol, and glycerin.

[0021] Preparation method: 1. Make the base solvent: put the base solvent into the reaction kettle and stir at 600 rpm for 10 minutes, 2. Add dispersant, penetrant, gas phase anti-sedimentation agent, water-based thickener, and alkaline regulator in sequence , adding interval time is 5-10min, 3. Add polycrystalline diamond powder and stir for 90min, after filling, ultrasonic for 45min; you can get sapph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com