A biomass gasification gas pipeline switch device

A gas pipeline and switchgear technology, applied in the field of biomass gasification, can solve the problems of high cost of water pipe switch, reduced switch flexibility, and unusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

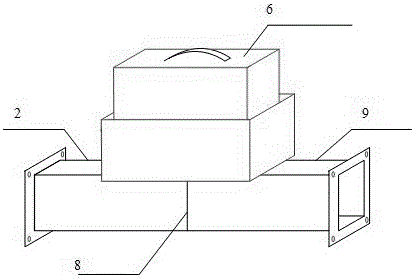

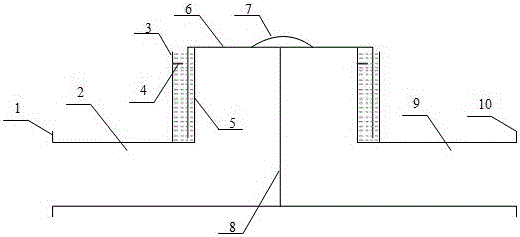

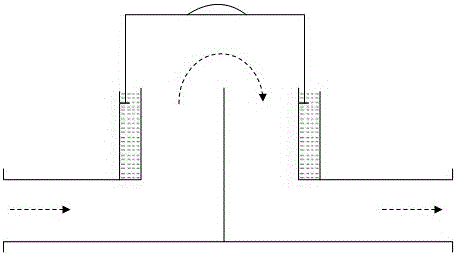

[0013] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach image 3 , the biomass gasification gas pipeline switch device described in this embodiment includes an intake enamel 1, an intake pipe 2, an outer edge of the water tank 3, a supporting plate 4, an inner edge of the water tank 5, a water tank cover 6, a cover handle 7, a gas stop Plate 8, air outlet pipe 9, and air outlet enamel 10, wherein the main body of the gas pipeline is composed of a square or circular pipe, one end of the main body is an air inlet pipe 2, the end of the air inlet pipe 2 is provided with an air inlet enamel 1, and the other end of the main body is an air outlet pipe 9. The end of the air outlet pipe 9 is provided with an air outlet enamel 10; the top of the main body between the air outlet pipe 9 and the air inlet pipe 2 is provided with an inspection port, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com