Hard anodizing technological process for 7050 super-thick aluminum alloy

A technology of hard anodizing and process method, applied in the direction of anodizing, can solve the problem of no hard anodizing process, and achieve the effect of high cost and long order cycle.

Inactive Publication Date: 2015-11-25

HARBIN

View PDF7 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] A certain type of aircraft selected high-strength and high-toughness ultra-thick plate 7050T7451 in the process of aircraft design, with a thickness of 130mm for hard anodization. However, the current domestic 7050 aluminum alloy does not have such a thick plate, and the hard anodization of such materials Neither is the craft

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

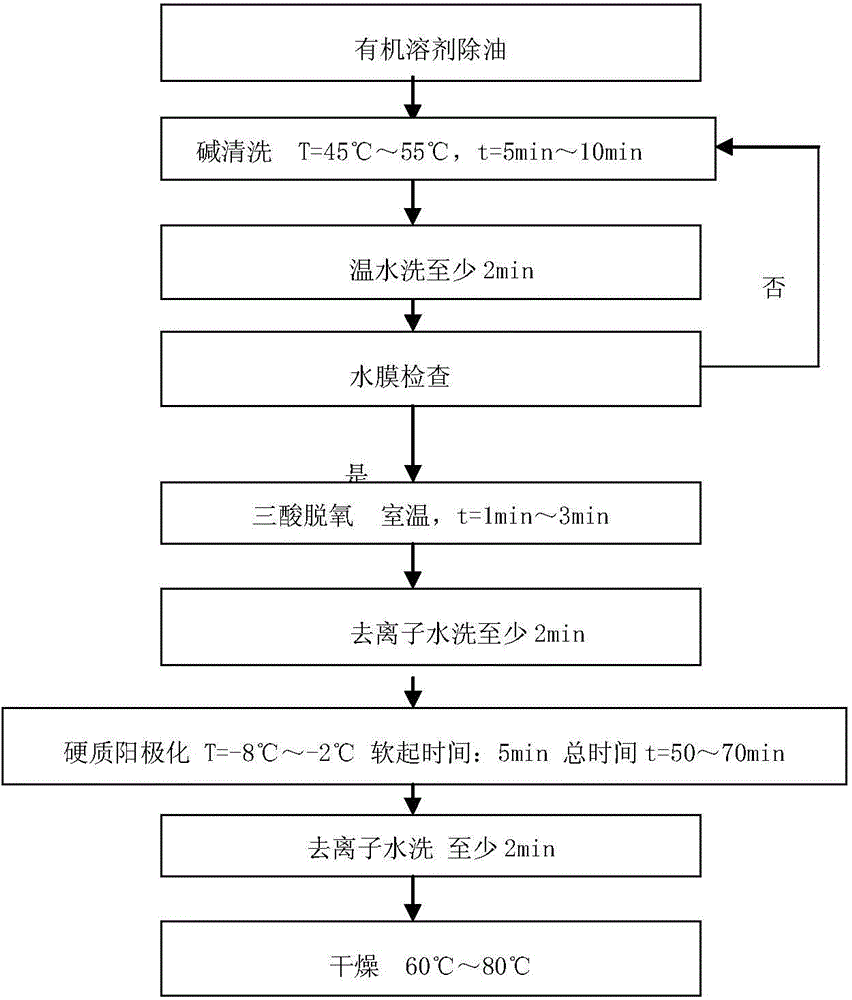

[0040] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

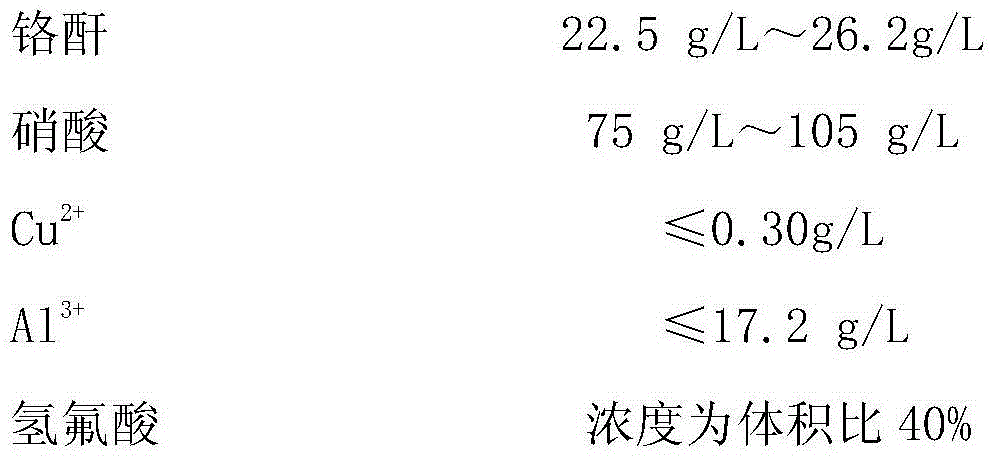

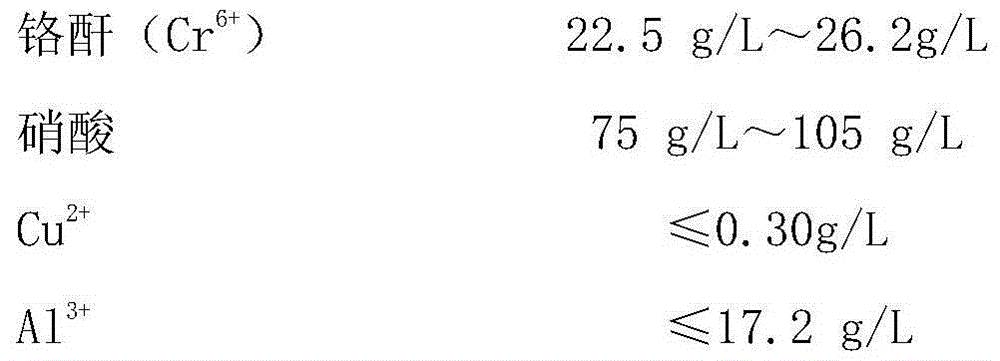

The invention belongs to hard anodizing technologies for super-thick aluminum alloy materials and particularly relates to a hard anodizing technological process for an 7050 super-thick aluminum alloy. Sulfuric acid is adopted as an electrolyte, a part is adopted as an anode, a lead plate is adopted as a cathode, direct current circulates, compressed air is used for stirring, and an electrochemical reaction of the electrolyte at low temperature is kept. An oxidation film which has the characteristics of high hardness, good abrasion resistance, heat resistance and insulating performance and the like is formed on the surface of a to-be-treated sample through the hard anodizing electrochemical reaction. Solution compositions are simple and stable, operation is convenient, and cost is low. A guarantee is provided for parts with special requirements in the fields of aviation, spaceflight, shipbuilding and the like.

Description

technical field [0001] The invention belongs to the aluminum alloy hard anodization technology, and in particular relates to a hard anodization process method of 7050 ultra-thick aluminum alloy. Background technique [0002] The development and engineering application of domestic high-strength and high-toughness aluminum alloy super-standard pre-stretched plates closely revolves around the model design requirements, and on the premise of new materials and new processes that have a certain domestic development and application basis, the rigidity of 7050-T7451 thick plates is carried out Research on the performance of various anodizing processes to achieve domestic independent guarantee of key materials. [0003] A certain type of aircraft selected high-strength and high-toughness ultra-thick plate 7050T7451 in the process of aircraft design, with a thickness of 130mm for hard anodization. However, the current domestic 7050 aluminum alloy does not have such a thick plate, and ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D11/04

Inventor 李艳梅万杰陈静高玉娥孙浩陈桂洪

Owner HARBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com