Steel bar connecting device for precast concrete component and steel bar connecting method for precast concrete component

A prefabricated assembly and connection device technology, applied in the direction of building components, structural elements, building reinforcements, etc., can solve the problems of high centering accuracy requirements for connected steel bars, uneven thickness of concrete protective layer, difficulties in concrete pouring and vibration, etc. , to achieve the effect of high construction efficiency, high practical value and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

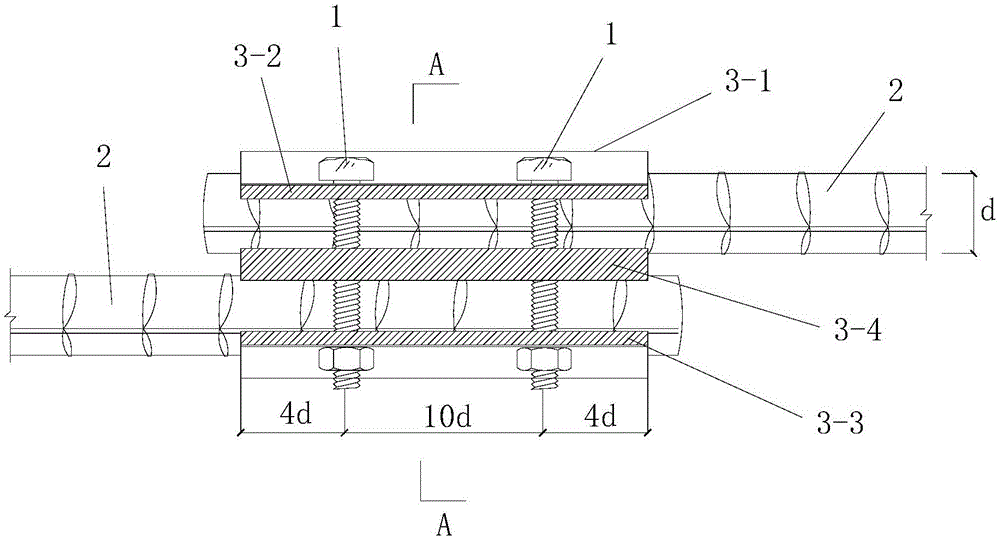

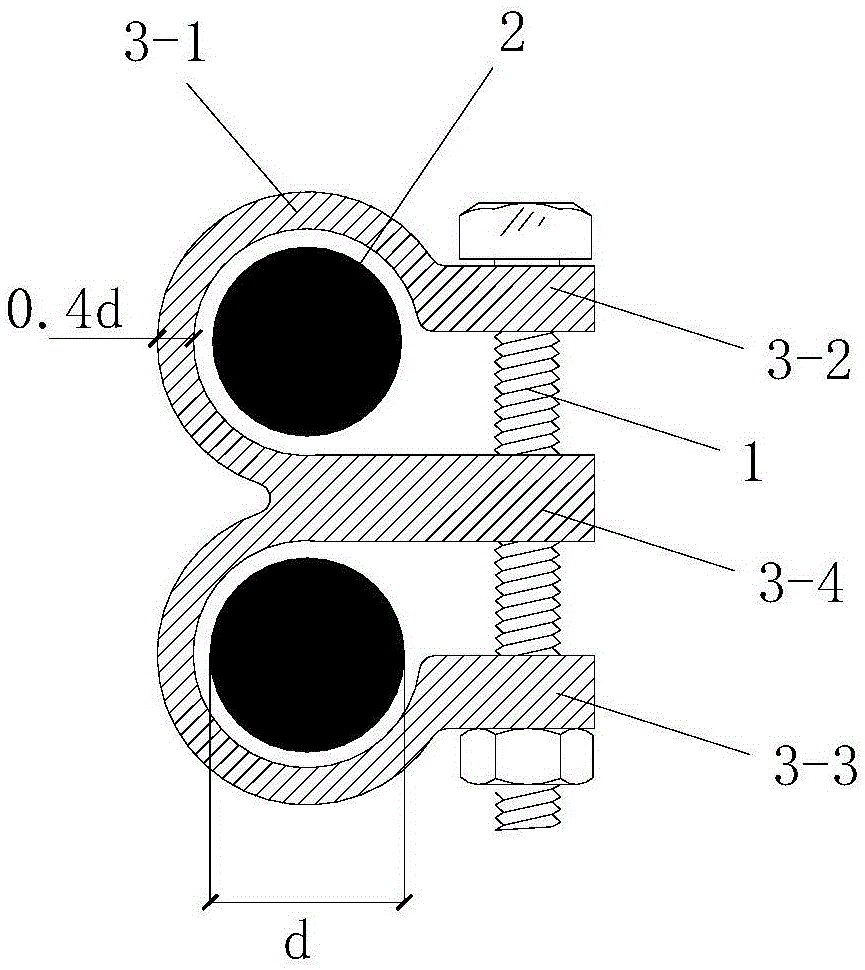

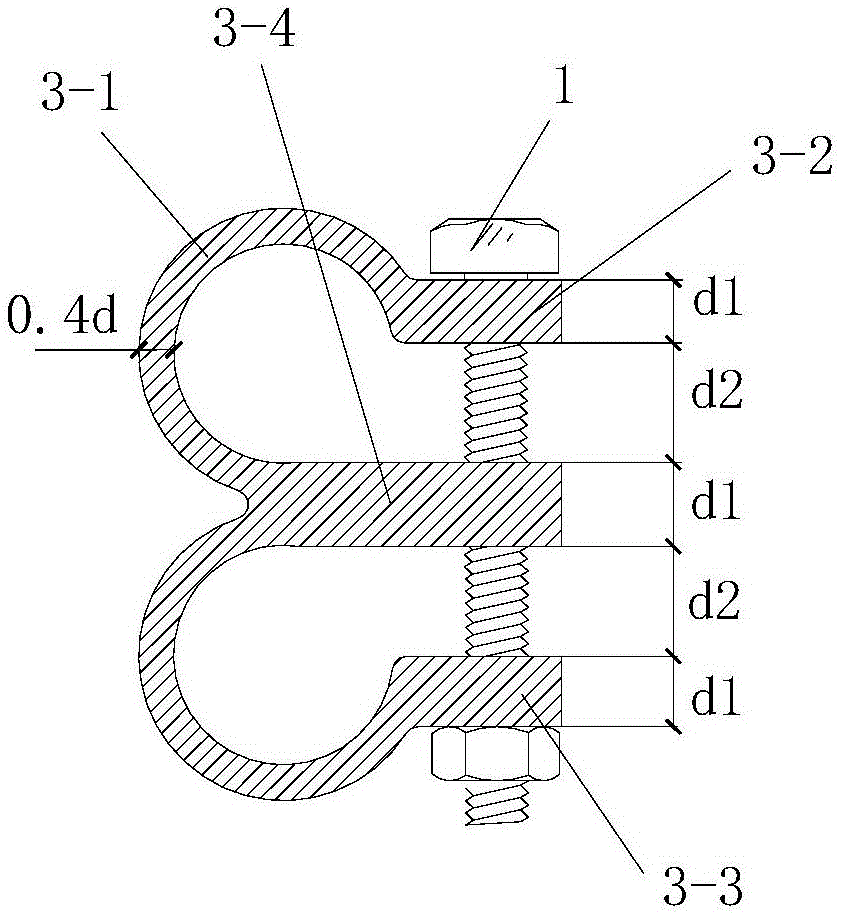

[0032] Such as figure 1 , figure 2 and image 3The shown prefabricated assembly type concrete component steel bar connection device includes a clamp clamped at the joint between two steel bars 2 and a plurality of connecting bolts 1 installed on the clamps. The clamps For steel clamps. The hoop includes an outer hoop body 3-1 set on the two steel bars 2 and three connecting plates arranged outside the outer hoop body 3-1, the outer hoop body 3-1 is 3-shaped and consists of Two arc-shaped plates are connected, and the two arc-shaped plates are respectively a first arc-shaped plate and a second arc-shaped plate located on one side of the first arc-shaped plate, and the inner part of the first arc-shaped plate The end is integrally connected with the inner end of the second arc-shaped plate. A plurality of the connecting bolts 1 are mounted on the three connecting plates, and the three connecting plates are provided with a plurality of bolt mounting holes respectively for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com