Gas well intelligent adjustment production method and device

A technology of intelligent adjustment and production method, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

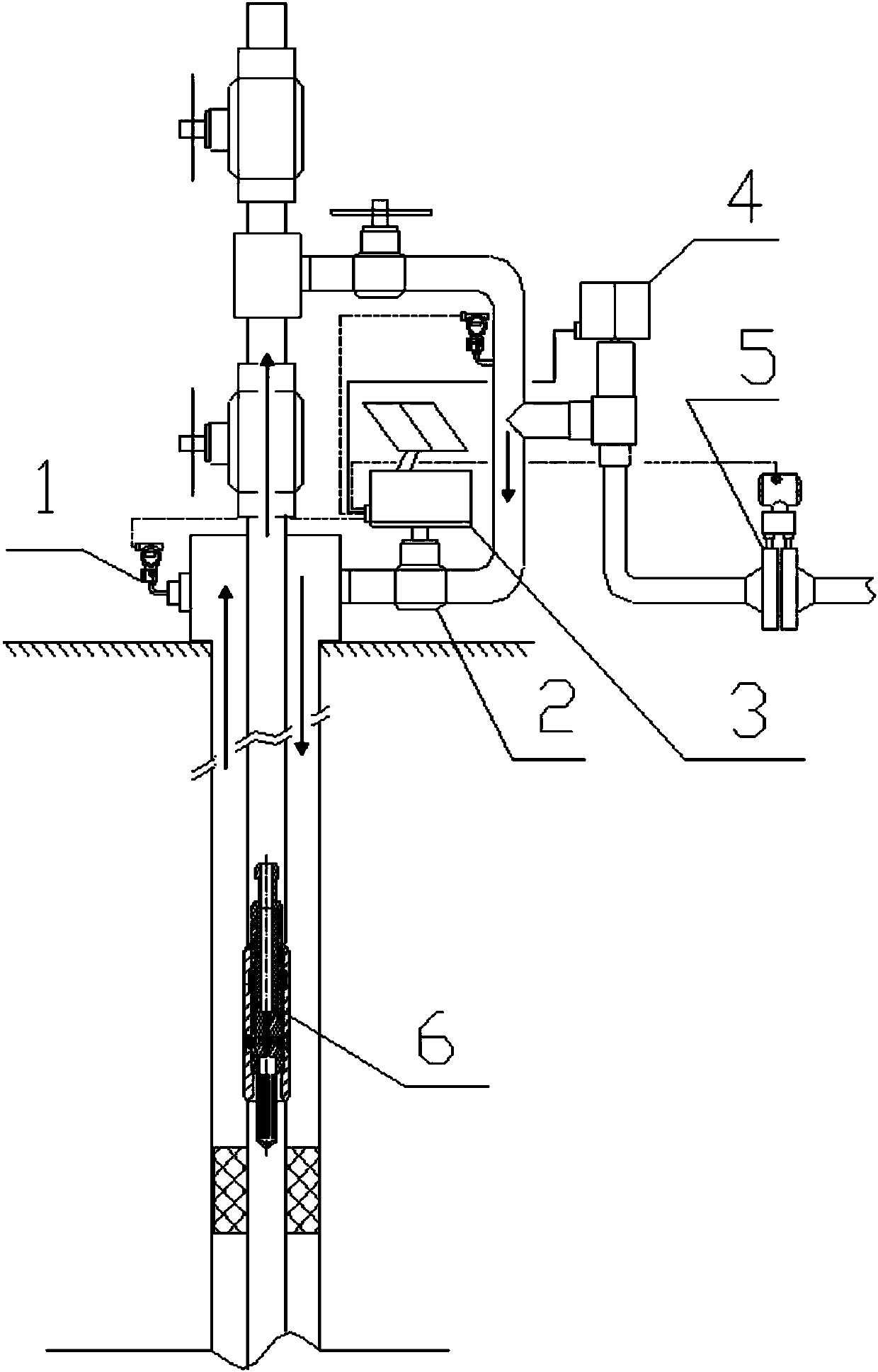

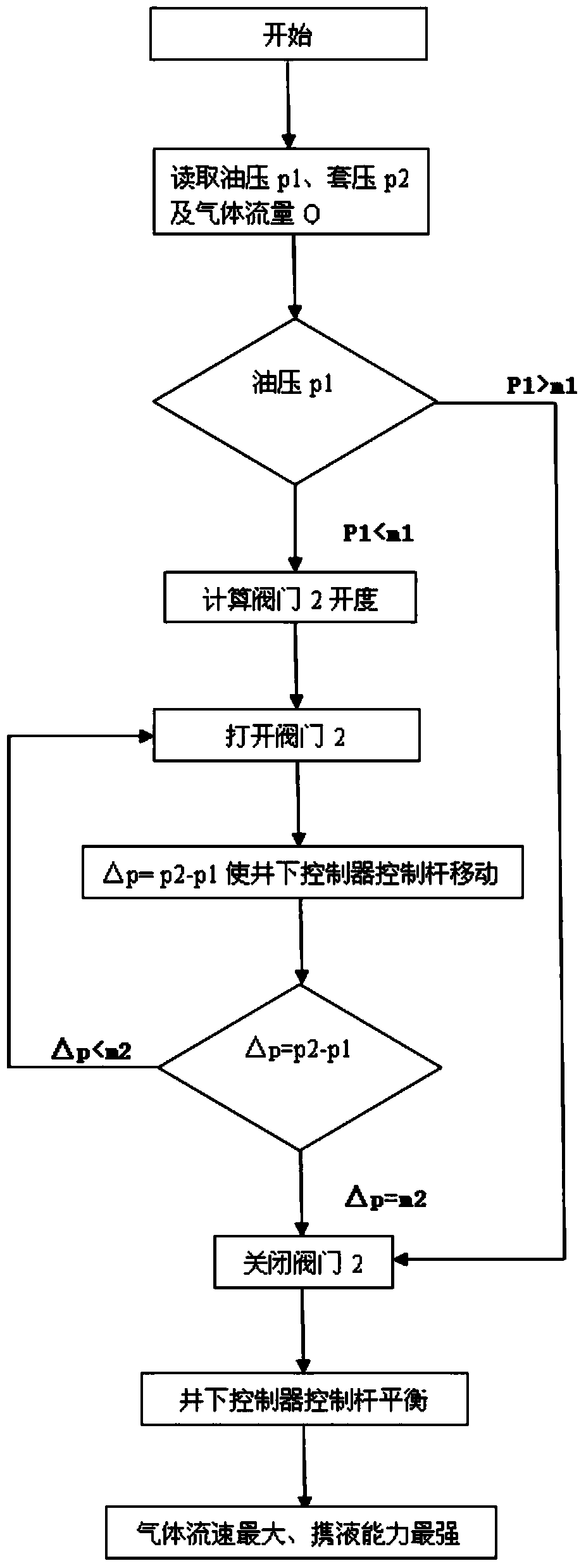

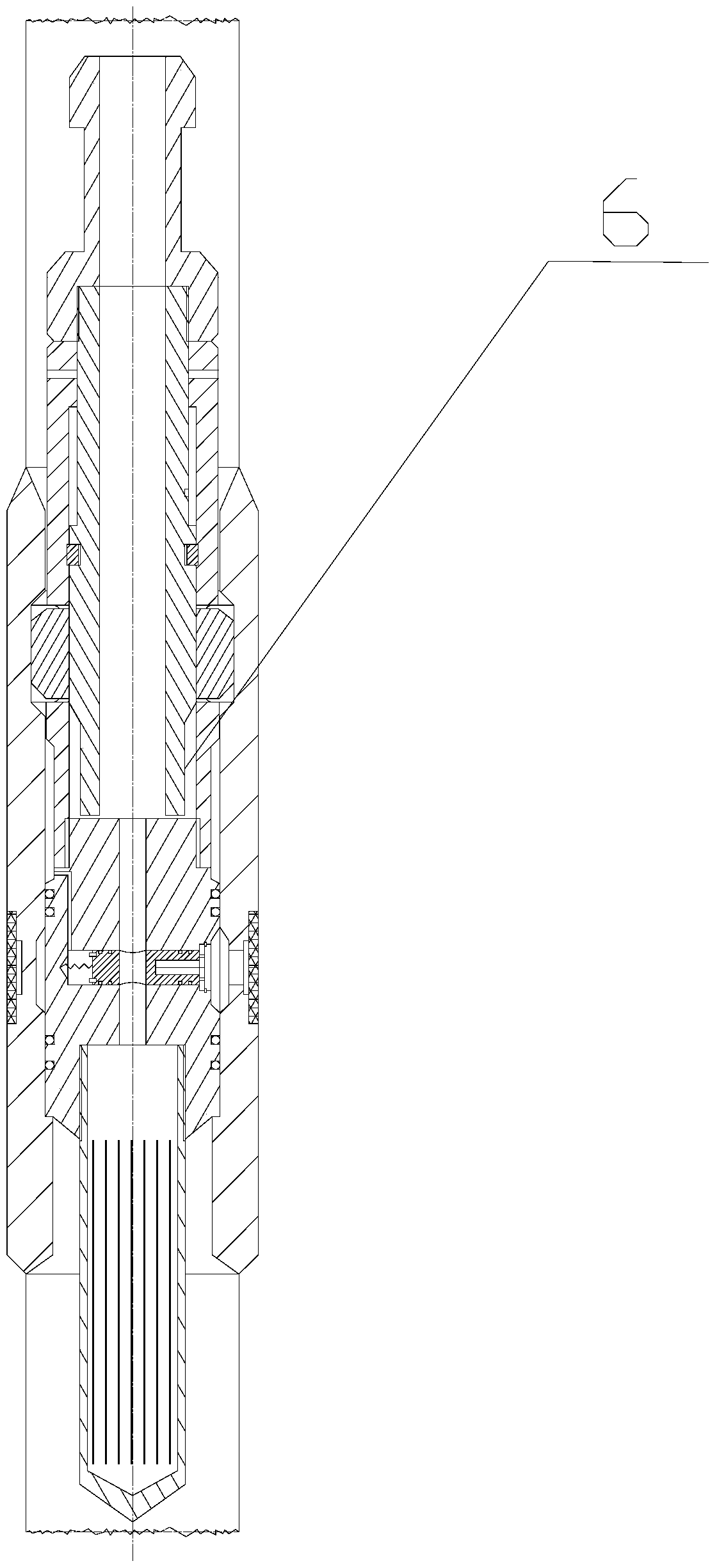

[0026] Embodiment 1: as Figures 1 to 5 as shown,

[0027] A gas well intelligent adjustment production method solves the problem of excessive liquid accumulation or water production in the wellbore and near the bottom of the gas well, and can better and more eliminate the bottom liquid accumulation, reduce the cost of drainage and gas recovery, and prolong the production time of the gas well.

[0028] An intelligent adjustment production system for a gas well includes a surface control system and an underground execution system. Among them, the surface control system includes pressure sensors, control valves, control boxes, electric control needle valves, flow meters, etc.; the downhole execution system is mainly downhole controllers.

[0029] The control box 3 is connected to the pressure sensor 1, the control valve 2, the electric control needle valve 4 and the flow meter 5, and the downhole controller 6 is installed in the downhole channel at the wellhead;

[0030] One s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com