Cooling, heating and power combined supply system based on double-pressure organic Rankine cycle

A technology of cogeneration of cooling, heating and power, and Rankine cycle, which is applied in the direction of mechanical equipment, steam engine devices, machines/engines, etc., can solve the problems of heat island effect in surrounding areas, discharge a large amount of condensation waste heat, and waste energy, and achieve simple structure and reduce Waste and high heat recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

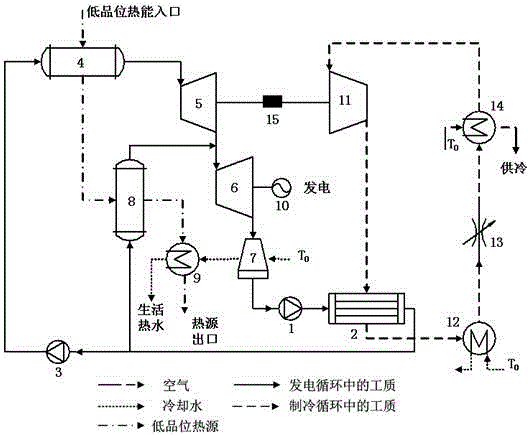

[0022] As shown in the accompanying drawings, the present invention shows a combined cooling, heating and power system based on a dual-pressure organic rankine cycle. The system is mainly composed of a dual-pressure organic rankine cycle and a vapor compression refrigeration cycle. Drive the high-pressure expander, and the high-pressure expander drives the compressor of the refrigeration cycle through the transmission device to provide cold energy to the outside; the low-pressure expander drives the generator to output electric energy to the outside; after the low-grade heat is released in the high-temperature regenerator, it will be The water is heated into domestic water and supplied to users. The main components of the system include: low-pressure working medium pump 1, low-temperature regenerator 2, high-pressure working medium pump 3, high-temperature evaporator 4, high-pressure expander 5, low-pressure expander 6, first condenser 7, low-temperature evaporator 8. High tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com