Method and diagnostic unit for diagnosing a differential pressure sensor

A sensor and pressure difference technology, which is applied to the pressure difference measurement between multiple valves, the diagnostic device of the exhaust gas treatment device, the instrument, etc., can solve the problems such as the inability to realize the identification of the connecting parts, and achieve the reduction of risk and the time gradient Elevate, realize the effect of recognition and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

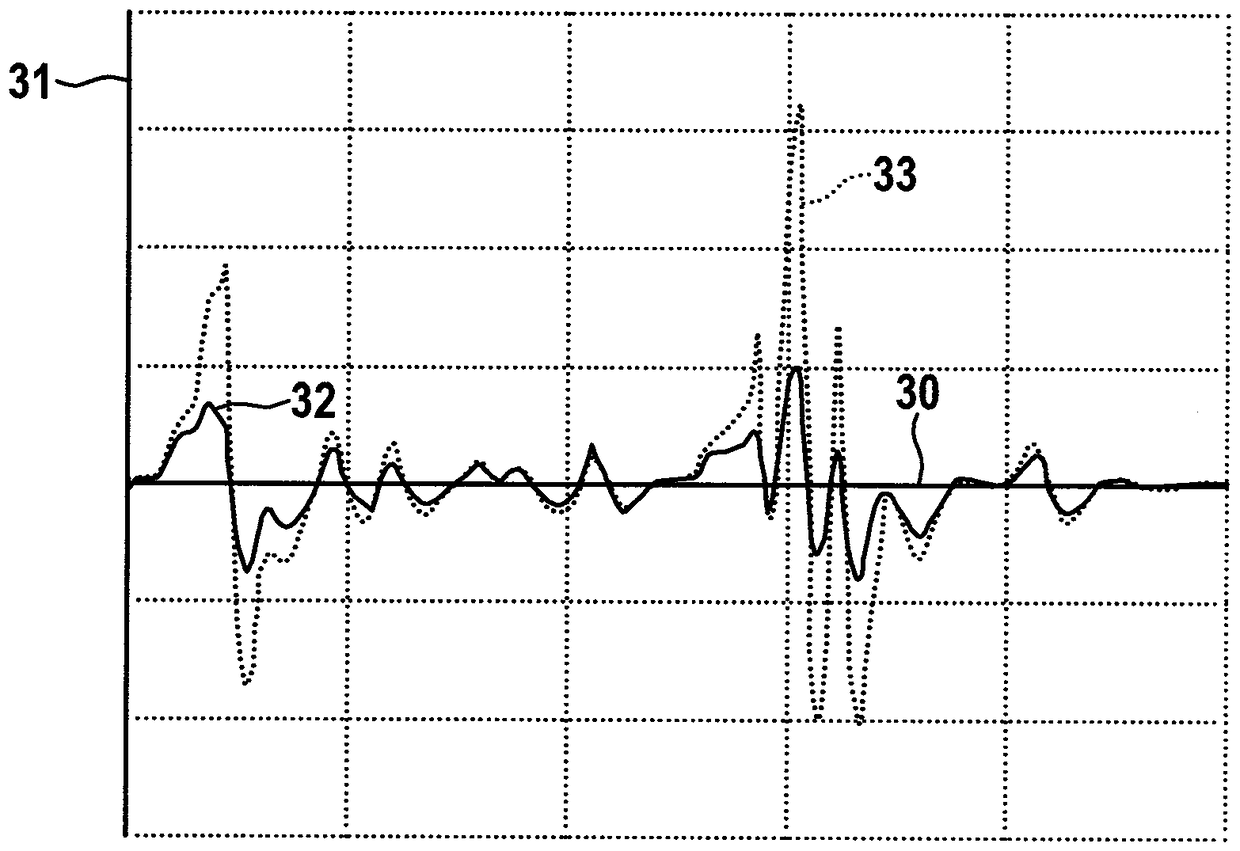

[0039] figure 1 The technical field in which the invention can be used is shown in a schematic diagram in an embodiment variant. In this case, the illustration is limited to the components necessary for the description of the invention. An internal combustion engine 10 is shown as an example, which is embodied as an Otto motor, wherein the exhaust gas of the internal combustion engine 10 is discharged via an exhaust gas line 11 . A multi-stage exhaust gas cleaning system is arranged in the exhaust gas line 11 . Furthermore, a catalytic converter 12 embodied as a three-way catalytic converter and a particle filter 13 are arranged as exhaust gas aftertreatment units along the exhaust gas line 11 in the flow direction of the exhaust gas flow 14 . A silencer 17 is arranged downstream of the particle filter 13 .

[0040] For diagnosing the particle filter 13 , a differential pressure sensor 15 is connected, with which a pressure difference between the filter inlet and the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com