Multistage finned tube capable of restraining frost formation and intensifying natural convection

A technology of natural convection and finned tubes, which is applied in the direction of tubular elements, lighting and heating equipment, heat exchange equipment, etc., can solve the problem of poor heat exchange performance of LNG air-temperature vaporizer, large influence of air-temperature vaporizer, Problems such as low outlet temperature of the gasifier, to achieve the effect of improving distribution uniformity, small influence, and large natural convection heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

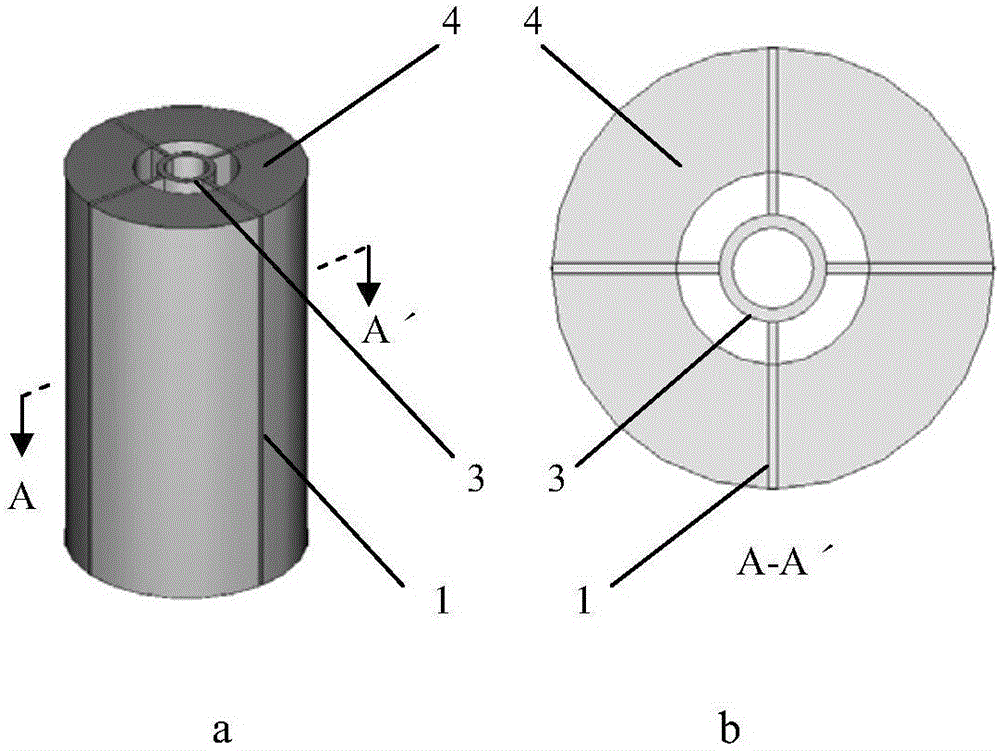

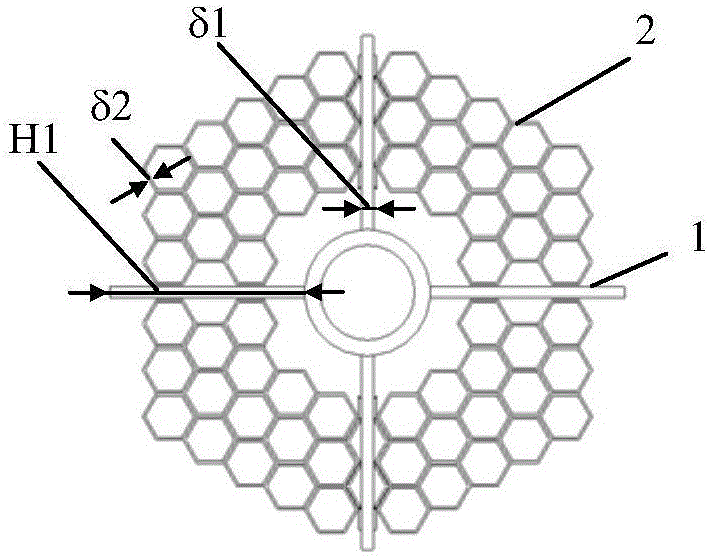

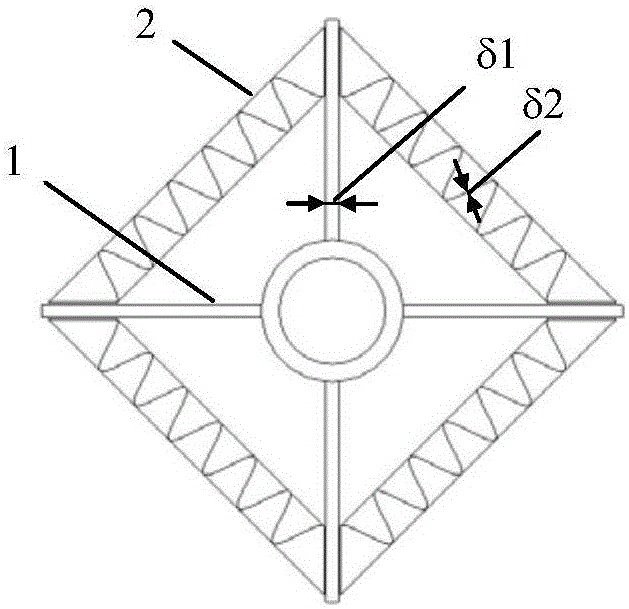

[0026] Such as figure 1 As shown, the multi-stage finned tube for suppressing frosting and enhancing natural convection of the present invention includes a central tube 3, a plurality of star-shaped primary fins 1 drawn from the surface of the central tube 3 and a connecting primary fin 1 The secondary fins 2 of the fins (both the primary fins and the secondary fins are longitudinal fins, the so-called longitudinal fins are parallel to the axis of the central tube), and the secondary fins 2 are closely connected with the primary fins 1 . All secondary fins 2 maintain a certain distance L1 from the central tube 3 . As a preferred embodiment of the present invention, said L1>10mm. The secondary fin 2 has a honeycomb structure ( Figure 2a ), corrugated fin structure ( Figure 2b ), grid fin structure ( Figure 2c ) or curved fin structure ( Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com