Clustered fiber Bragg grating sensor

A fiber grating and sensor technology, applied in the field of sensors, can solve the problems of low temperature detection resolution, cumbersome operation process, and large fusion loss, and achieve the effects of high detection resolution, simple operation process, and reduced fusion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

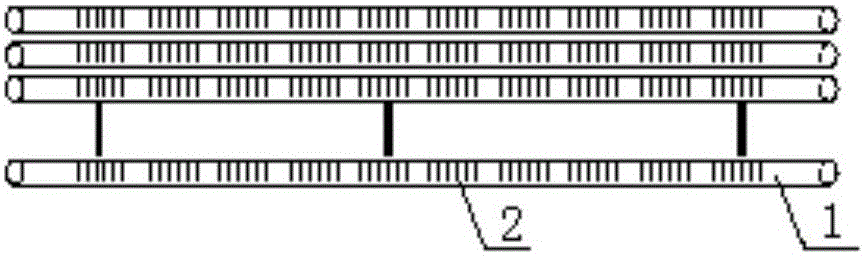

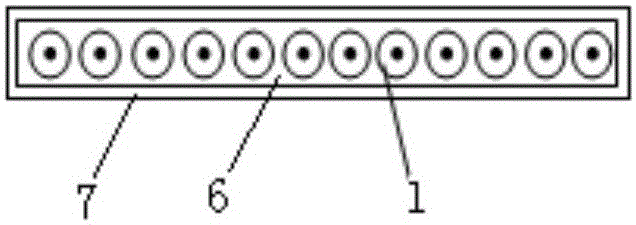

[0026] Such as figure 1 and figure 2 As shown, the bundled fiber grating sensor of the present invention includes twelve optical fibers 1, each of which is engraved with ten gratings 2, and the twelve optical fibers 1 engraved with ten gratings 2 adopt a planar bundled packaging method. The specific structure is as follows: twelve optical fibers 1 are distributed horizontally and in parallel, there are intervals between adjacent optical fibers 1 , and the distance between optical sensing centers of optical fibers 1 engraved with multiple gratings 2 is greater than 0.5 mm. In addition, the distance between the gratings 2 on the same optical fiber 1 is greater than or equal to 2mm, and twelve optical fibers 1 are located in a square protective sleeve 7 at the same time. The bundled optical fiber protection filler 6 is made of high temperature resistant fiber or thixotropic colloid. Square protective sleeves are generally made of metals such as ceramics and aluminum, and therm...

Embodiment 2

[0028] Such as image 3 As shown, the bundled fiber grating sensor of the present invention includes six optical fibers 1, each of which is engraved with a plurality of gratings 2, and the six optical fibers 1 engraved with a plurality of gratings 2 adopt a bundled tube packaging method, and its specific structure is : six optical fibers 1 engraved with a plurality of gratings 2 are respectively stuck in the trapezoidal groove 9 of a support frame 8, and the support frame 8 is wrapped with an inner protective sheath 10, a tape 11 and an outer protective sheath 12 from inside to outside. There are intervals between adjacent optical fibers 1, and the distance between the optical sensing centers of optical fibers 1 engraved with multiple gratings 2 is greater than 0.5mm. In addition, the distance between the gratings 2 on the same optical fiber 1 is greater than or equal to 2 mm. The strap 11 can be made of non-metal such as polyester plastic or metal such as aluminum strip and ...

Embodiment 3

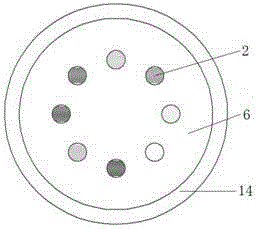

[0030] Such as Figure 4 As shown, the bundled fiber grating sensor of the present invention includes seven optical fibers 1, and each optical fiber 1 is engraved with a plurality of gratings 2, and a plurality of optical fibers 1 engraved with a plurality of gratings 2 adopts a bundled tube bundle packaging method, and its specific The structure is: seven optical fibers 1 engraved with multiple gratings 2 are concentrated in the middle of the inner protective sheath 10, there is an interval between adjacent optical fibers 1, and the optical sensing center distance of the optical fibers 1 engraved with multiple gratings 2 is greater than 0.5mm . In addition, the distance between the gratings 2 on the same optical fiber 1 is greater than or equal to 2 mm. Twelve reinforcing ropes 13 are distributed on the outer peripheral surface of the inner protective sheath 10 along the circumferential direction, and the outer protective sheath 12 is wrapped on the twelve reinforcing ropes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com