Seawater sampling site suction filtration device

A suction filtration device, on-site technology, applied in sampling devices, preparation of test samples, etc., can solve the problems of sample loss, increased risk, complicated steps, etc., to achieve fast and efficient suction filtration, improve work efficiency, and easy to use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

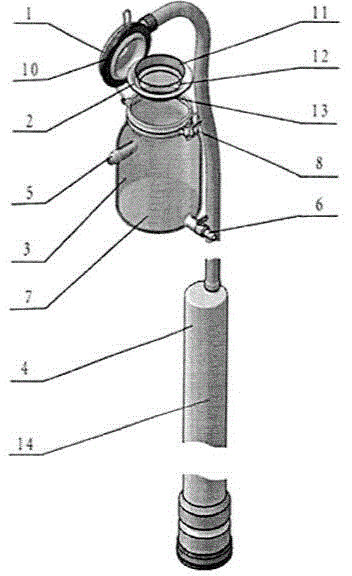

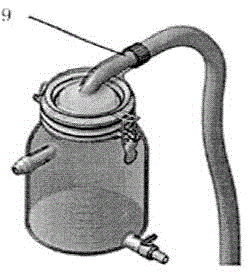

[0012] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

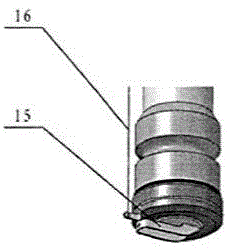

[0013] The specific embodiment of the present invention is shown in the figure, this kind of seawater sampling on-site filtering device is composed of a bottle stopper 1, a filter tray 2, a bottle body 3, and a sampling tube 4, and is characterized in that the bottle stopper 1 is provided with a sampling tube Joint 9, sealing ring 10; the lower edge of the filter tray 2 is provided with a sealing strip 13, the glass sand chip 12 is placed flat in the filter tray 2, and the filter membrane 11 is placed flat on the glass sand chip 12; the bottle stopper 1 is fixed by the buckle of the bottle stopper 8 is sealed and connected with the bottle body 3, and the filter tray 2 is pressed tightly, and the bottle stopper 1 and the bottle body 3 are sealed airtight through the sealing ring 10 and the sealing rubber strip 13; the bottle body 3 is provided with an air extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com