Fine particle measuring device and measuring method

A fine particle and measuring device technology, applied in the direction of measuring device, particle suspension analysis, suspension and porous material analysis, etc., can solve the problems of PM2.5 measurement error and unknown particle density, and achieve the effect of eliminating influence and measuring accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

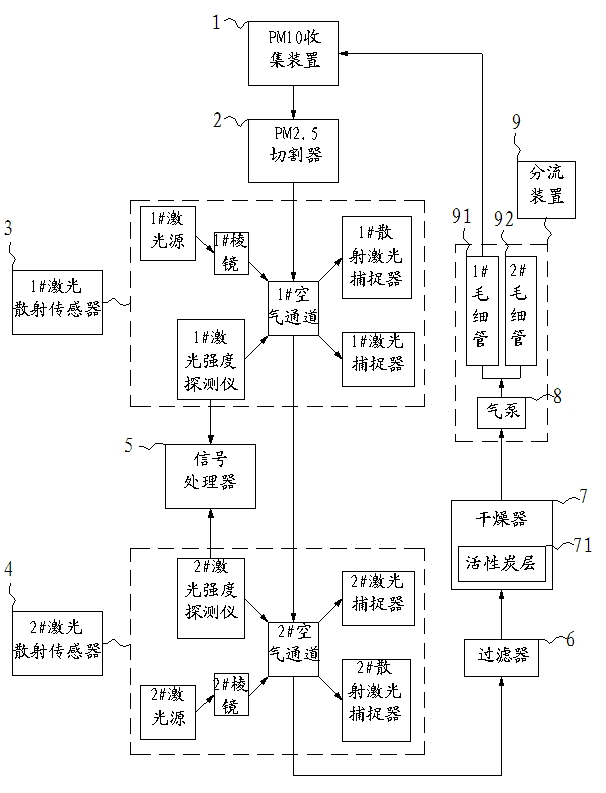

[0043] see figure 1 , figure 2 as well as image 3 , as shown in the legend therein, a fine particle measuring device is used to detect the content of PM2.5 in the air, comprising a PM10 collector 1 for collecting air samples, a device for separating fine particles in the air samples A PM2.5 cutter 2, a detection device for detecting the content of fine particles in air samples, a filter 6 for collecting fine particles in air samples, a dryer 7 for removing moisture in air samples, and An air pump 8 based on a stable air flow and a flow splitting device 9 for recycling the purified residual gas, the detection device includes,

[0044] A 1# laser scattering sensor 3, used to measure the scattering intensity of fine particles in air samples;

[0045] A 2# laser scattering sensor 4, used to measure the scattering intensity of fine particles in air samples;

[0046] a signal processor 5, configured to convert the scattering intensity of the fine particles into the concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com