Corrosion Evaluation Method of Injection-production String Under the Joint Action of Alternating Load and Corrosive Medium

A technology for injection-production strings and corrosive media, applied in the field of corrosion evaluation of injection-production strings, to achieve the effects of avoiding injection and production stoppages, good economic and social benefits, and reducing failure hazards and risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides an experimental method for evaluating the corrosion of injection-production strings under the combined action of alternating loads and corrosive media. Injection-production string Injection-production string material.

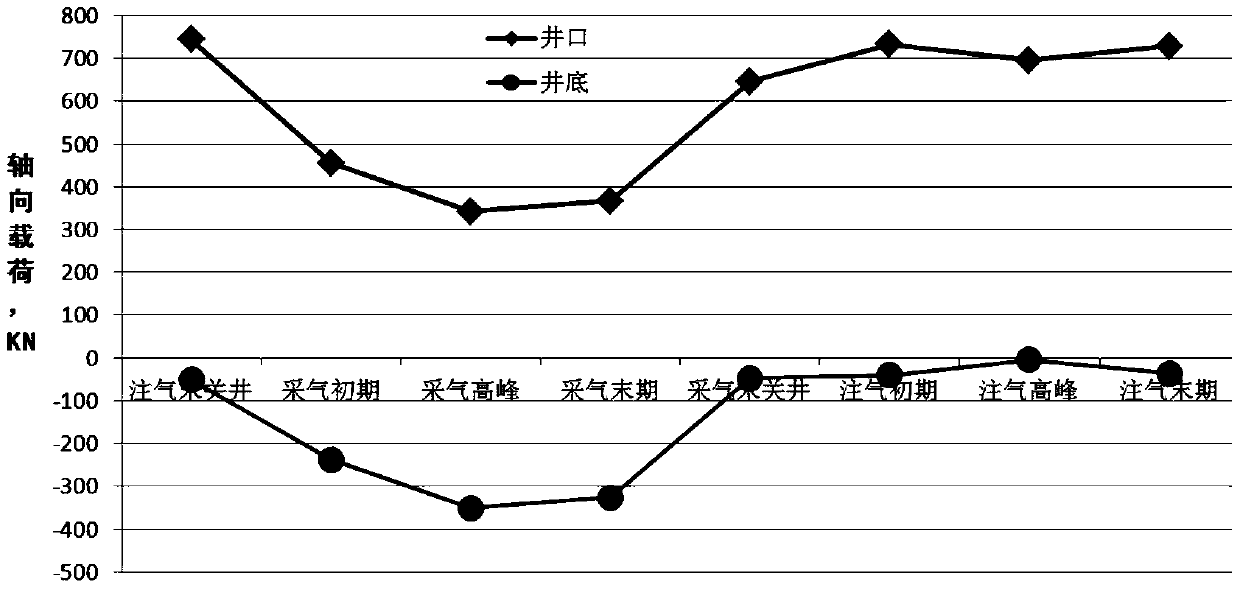

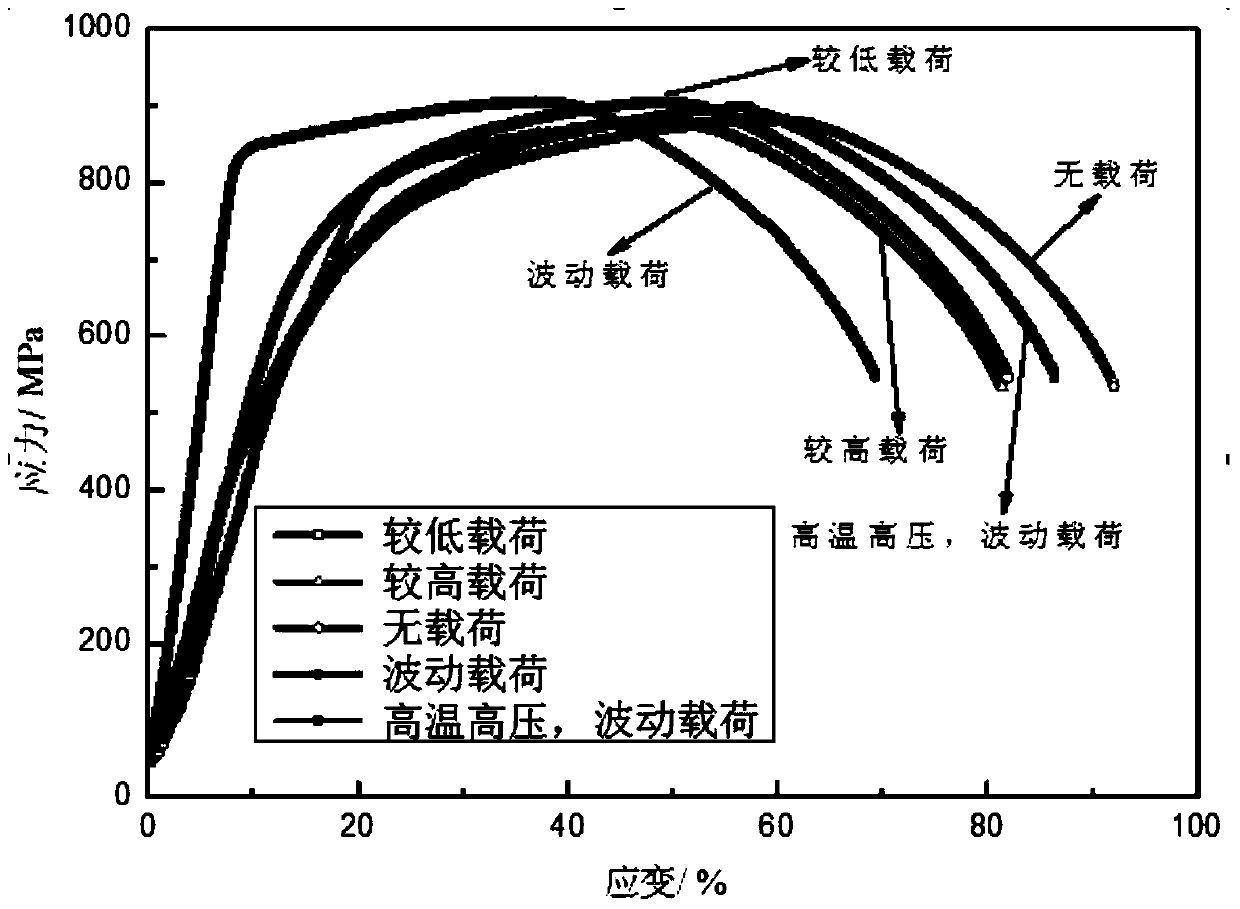

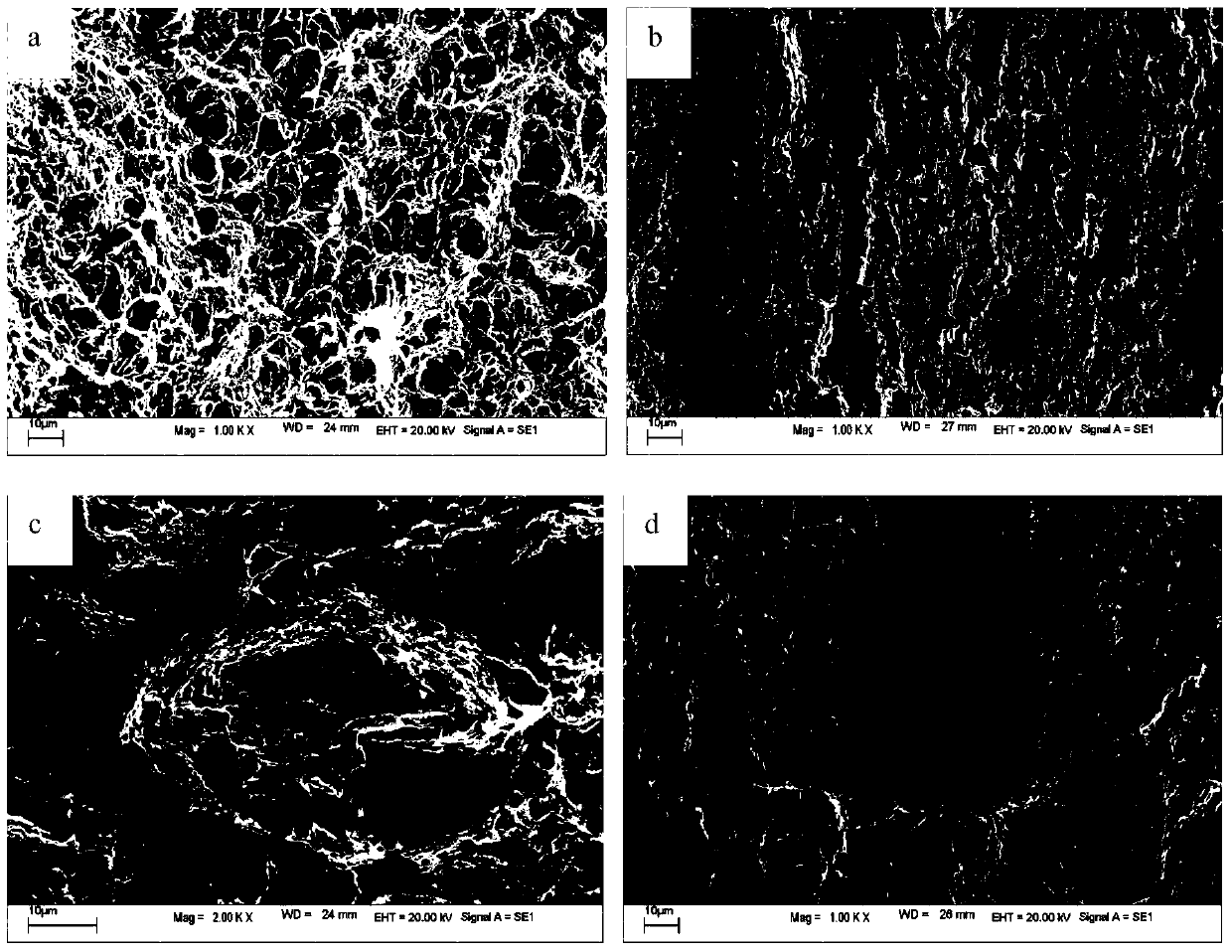

[0031] Taking XX gas storage as an example, the method includes: (1) collection of basic parameters; (2) extraction of axial load spectrum; (3) design of experimental comparison scheme; (4) environmental simulation of alternating load and corrosive medium interaction; (5) Experiment and result analysis, as follows:

[0032] (1) Basic parameter collection

[0033]During the operation stage of XX gas storage, the temperature changes from 55°C to 156°C, the pressure changes from 13.0MPa to 50.0MPa, the partial pressure of carbon dioxide is between 0.46MPa and 0.98MPa, and the hydrogen sulfide content is up to 29.3mg / m 3 , the highest partial pressure is 0.00047MPa, the chloride ion content is above 10000mg / L, and the corrosive enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com