Quantitative detection method and detection instrument for scale accumulation in pipeline

A quantitative detection method and oxide scale technology, applied in the direction of material magnetic variables, etc., can solve the problems of expensive detection devices, complex systems, affecting sensitivity, etc., achieve great advantages and application prospects, simple detection principle, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in detail below in conjunction with accompanying drawing:

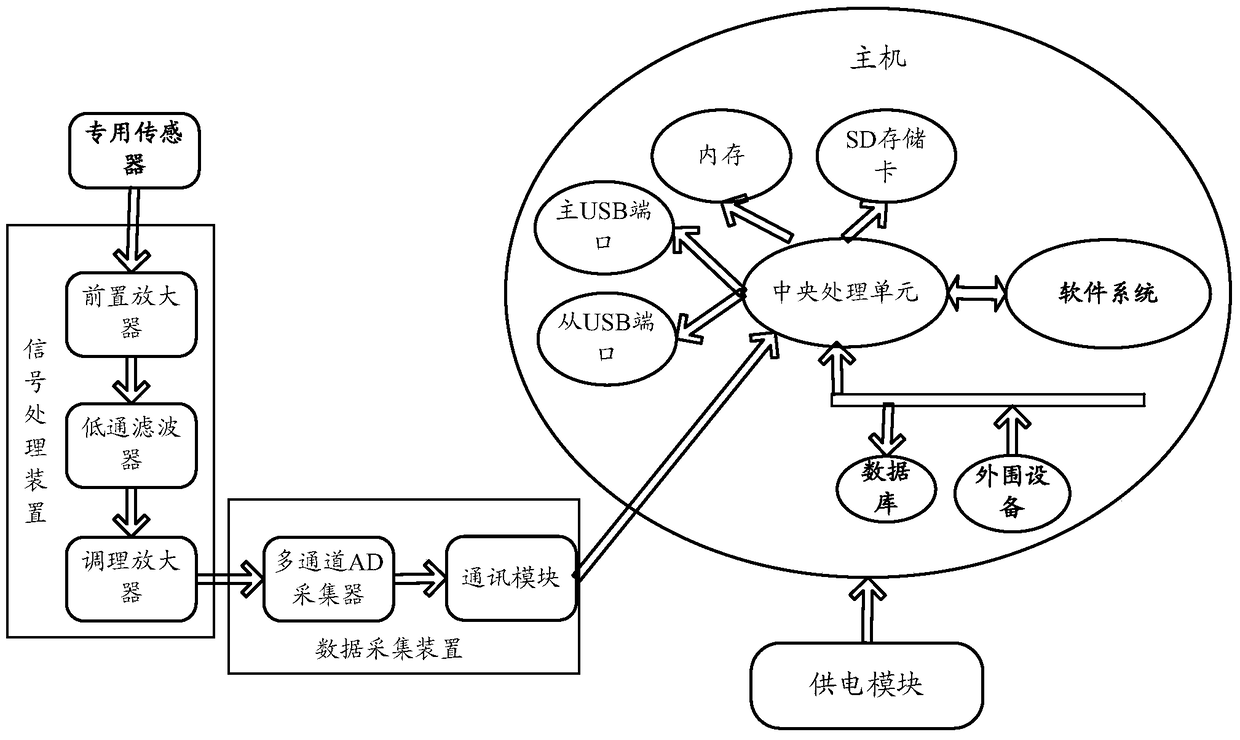

[0039]The quantitative detection method and detector for oxide scale accumulation in pipelines provided by the present invention can be widely used in the quantitative detection of oxide accumulation in austenitic stainless steel pipes to maintain the normal operation of austenitic stainless steel pipes in power plant boilers. On the one hand, it can quickly and effectively Detect the peeling and accumulation of magnetic oxides inside the stainless steel tubes of power station boilers, and prevent the dangerous situation of tube explosion caused by excessive magnetic oxides on stainless steel tubes; The overall oxidation and corrosion state provides effective data support and forms a comprehensive and series of power plant boiler evaluation and analysis technologies, which play an important role in ensuring the safe and reliable operation of power plant boilers. Using the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com