Online detection system for vibration of elevator traction motor

A detection system, elevator traction technology, applied in measurement devices, measurement of ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems that cannot be clearly reflected in the working conditions of traction motors, the measured vibration data is complex, and the structure of vibration detectors Complex problems, to achieve the effect of convenient disassembly, low maintenance cost, simple detection principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

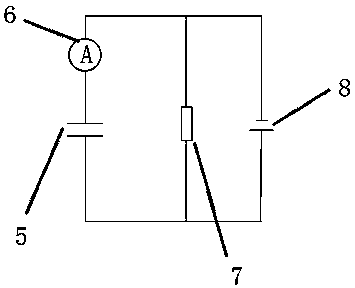

[0022] Such as figure 1 As shown, in the elevator traction motor vibration online detection system of the present invention, the power supply 8 provides electric energy for all electrical components of the detection system, and the power supply is a constant voltage power supply; the signal processing module collects and amplifies the data collected by the sensor , the signal processing module includes a signal amplifier 6 and a data collector, the signal amplifier 6 amplifies the signal of the sensor, and the data collector is used to collect the signal conveyed by the signal amplifier 6 .

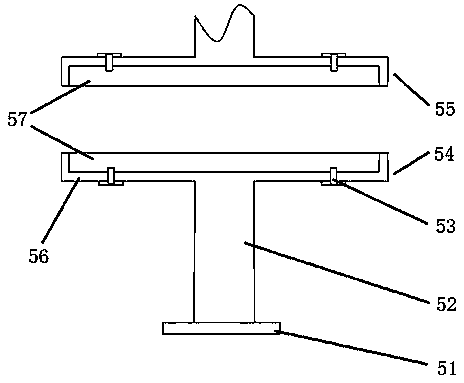

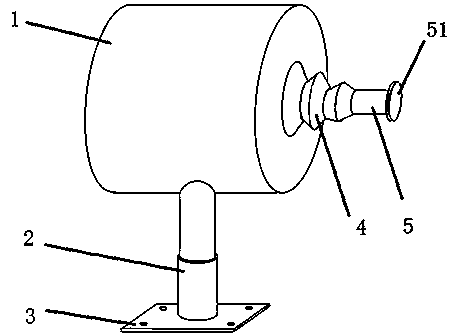

[0023] Such as image 3 and Figure 4 As shown, the sensor is used to collect the vibration signal of the traction motor, which includes a casing 1, a telescopic support 2, a base 3, a flexible sleeve 4 and a capacitor 5, and the capacitor includes a fixed plate 55 and a movable plate 54, so The telescopic bracket 2 is connected to the shell 1 and the base 3, and the base 3 is fixed on ...

Embodiment 2

[0030] The difference from Embodiment 1 is that the vibration sensors include multiple groups, installed on different working end faces of the traction motor, to detect the vibration of the motor in a more comprehensive manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com