Multi-axis turntable angle positioning error detection method based on single-axis laser gyro goniometer

A technology of laser gyro and multi-axis turntable, which is applied in Sagnac effect gyroscopes, instruments, measuring devices, etc., can solve the problem of inability to trace the source of the national angle measurement reference device, projection angle measurement error, angle Problems such as measurement errors, to achieve the effect of wide application range, simple detection installation and simple detection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

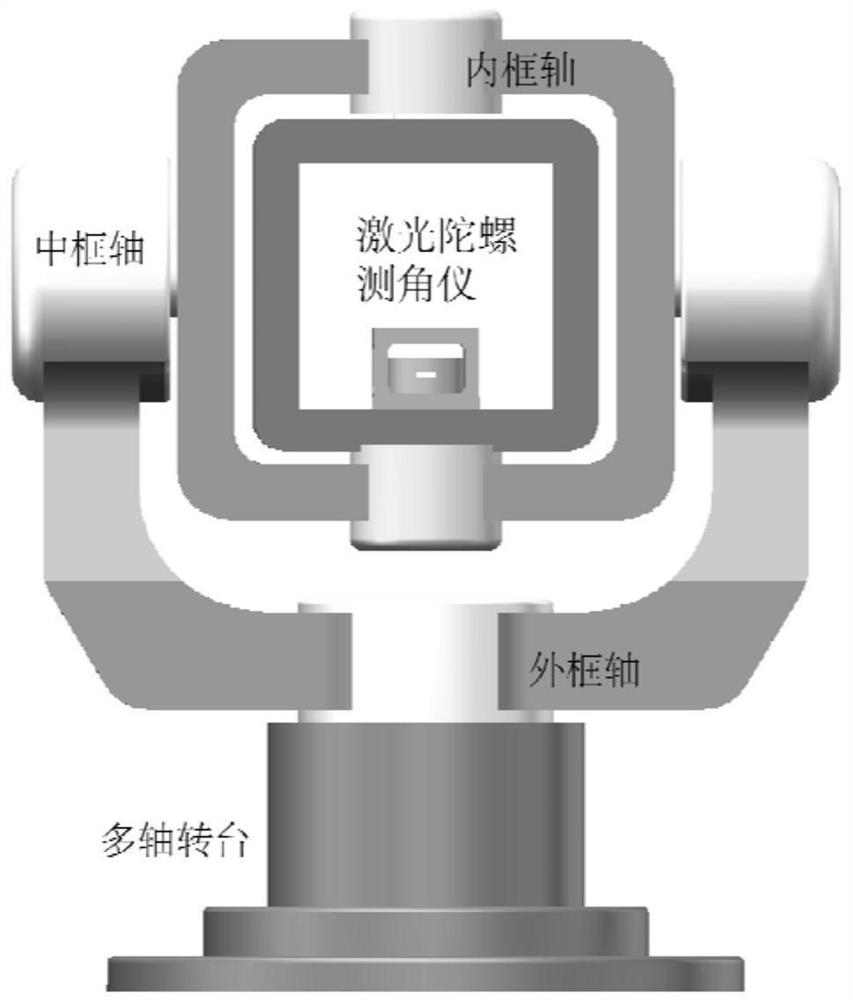

[0053] The specific embodiment of the present invention combines the angular attitude output of the multi-axis turntable itself and the angle measurement information of the single-axis laser gyro goniometer to judge and eliminate the angle measurement error measured by the single-axis laser gyro goniometer introduced by the rotation of the earth value to complete the detection of the angular positioning error of the multi-axis turntable.

[0054] Before discussing the specific embodiments of the present invention, the technical principles involved in the specific embodiments of the present invention will be discussed first.

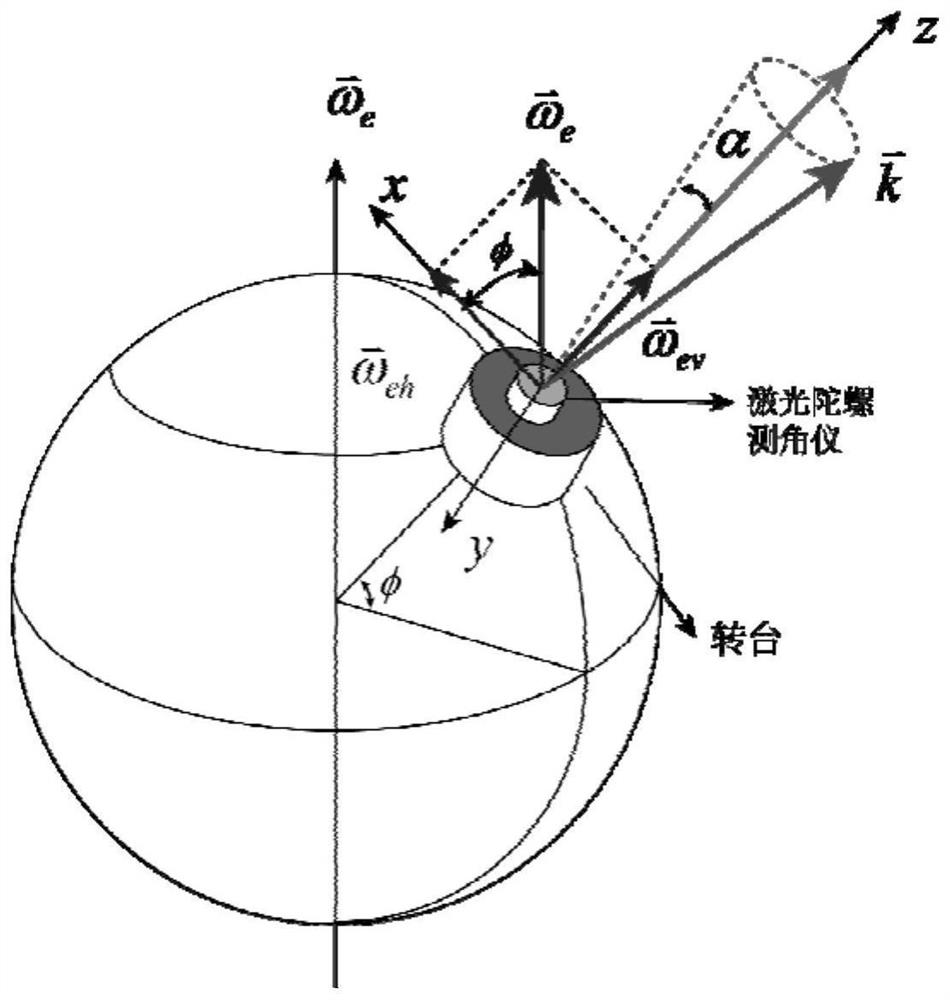

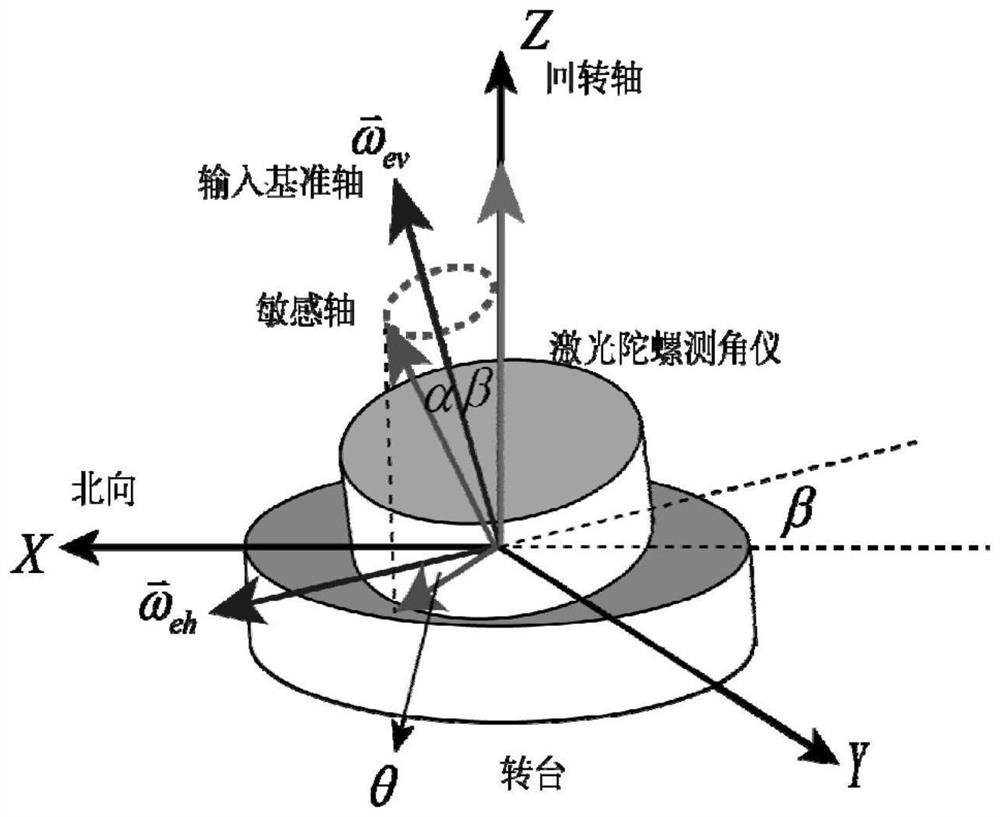

[0055] The technical principles involved in the specific embodiments of the present invention are as follows: figure 1 with figure 2 Shown:

[0056] The working principle of the single-axis laser gyro goniometer is based on the Sagnac effect. Its built-in laser generates helium-neon laser light. In a closed optical path made of triangular or square qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com