Gate-type automobile sampling machine

A sampling machine and portal technology, applied in the field of portal car sampling machine and sampling equipment, can solve the problems of large dust, complex locking mechanism, complex structure, etc., to avoid equipment damage, avoid sampling failure, and simple detection device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

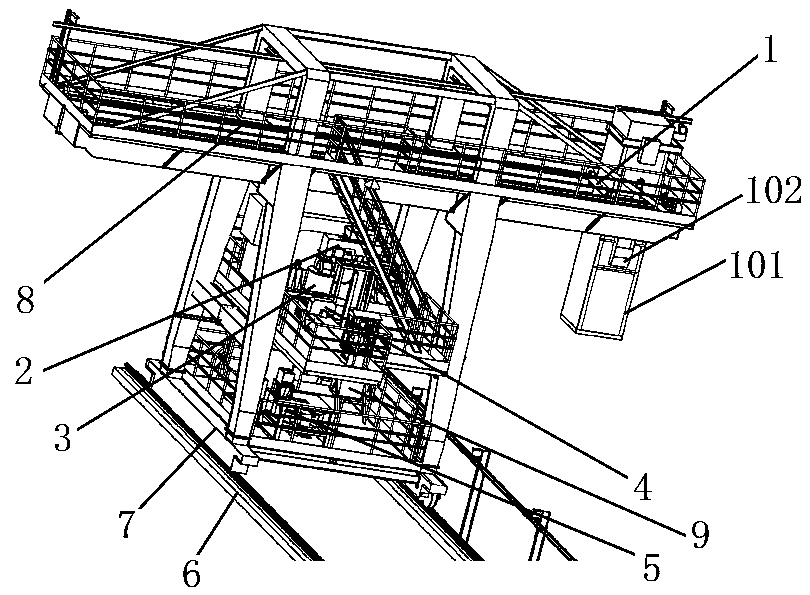

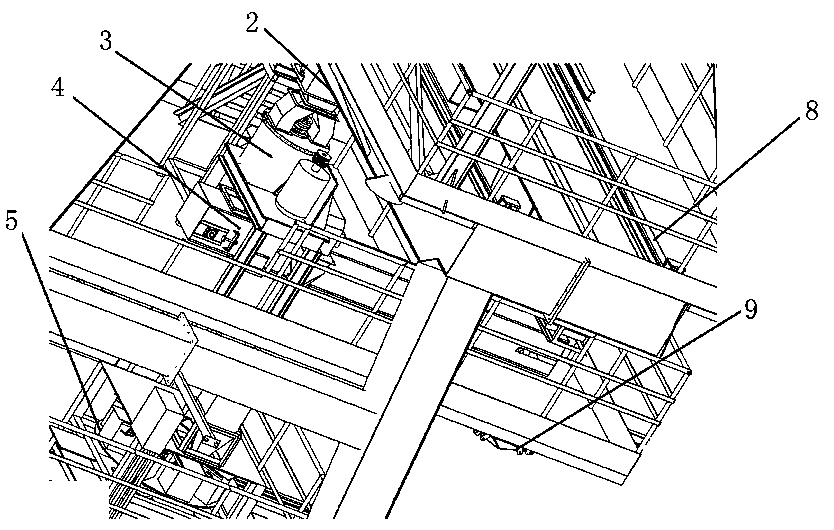

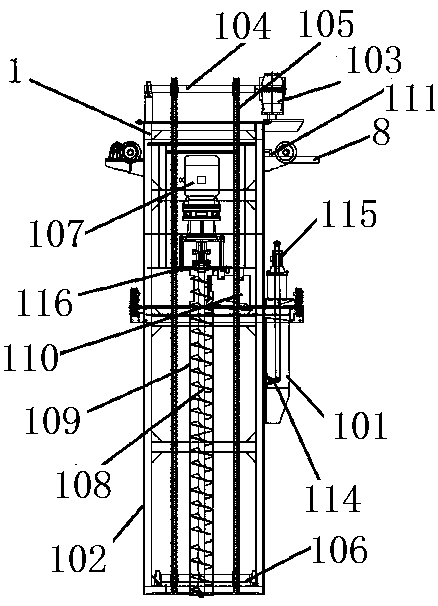

[0028]A further detailed explanation of the present invention is given in conjunction with the accompanying drawings. In the accompanying drawings, each label is: 1: sampling trolley; 2: first-class belt conveyor; 3: hammer crusher; 4: shrinking machine; 5: sample collector; 7: gantry cart; 8: rails in the left and right directions; 9: waste collection hopper; 10: feeding chute; 101: box; 102: intermediate hopper; 103: up and down drive motor; 104: output shaft of up and down drive motor; 105: chain; 106: sampling rack; 107: sampling motor; 108: screw shaft; 109: sampling cylinder; 110: discharge port; 111: vibration detection sensor; : electric push rod D; 116: lifting platform; 117: driving sprocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com