Method for fast diagnosing direction connection of big power rectifier switch tube online

A rectifier switching tube, through-fault technology, used in instruments, measuring devices, measuring electricity and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

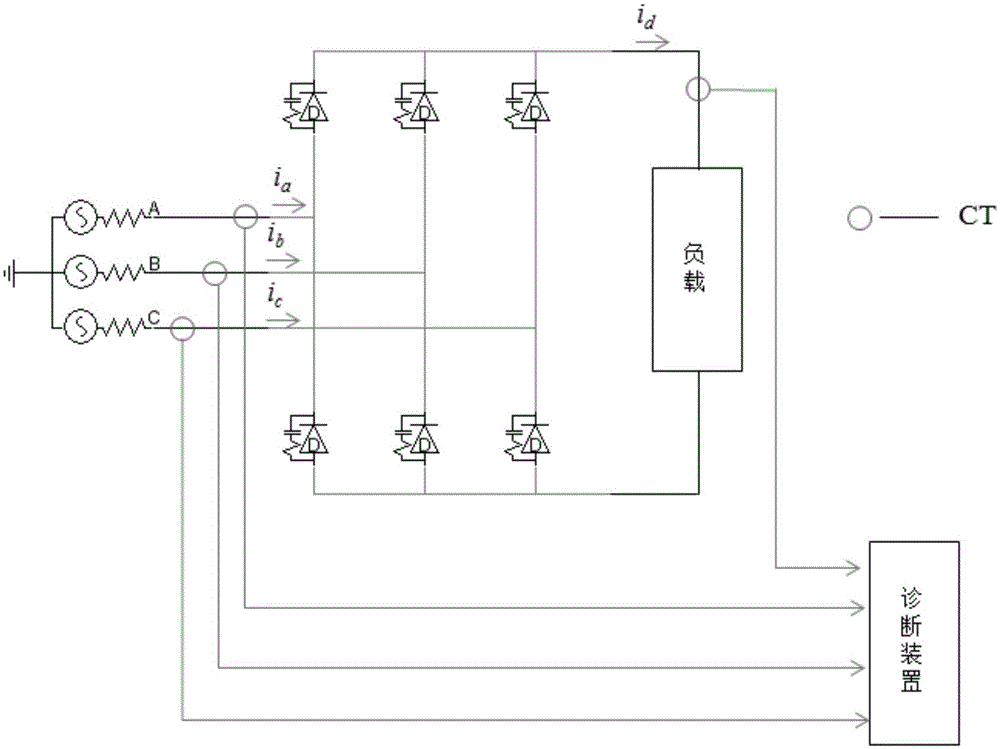

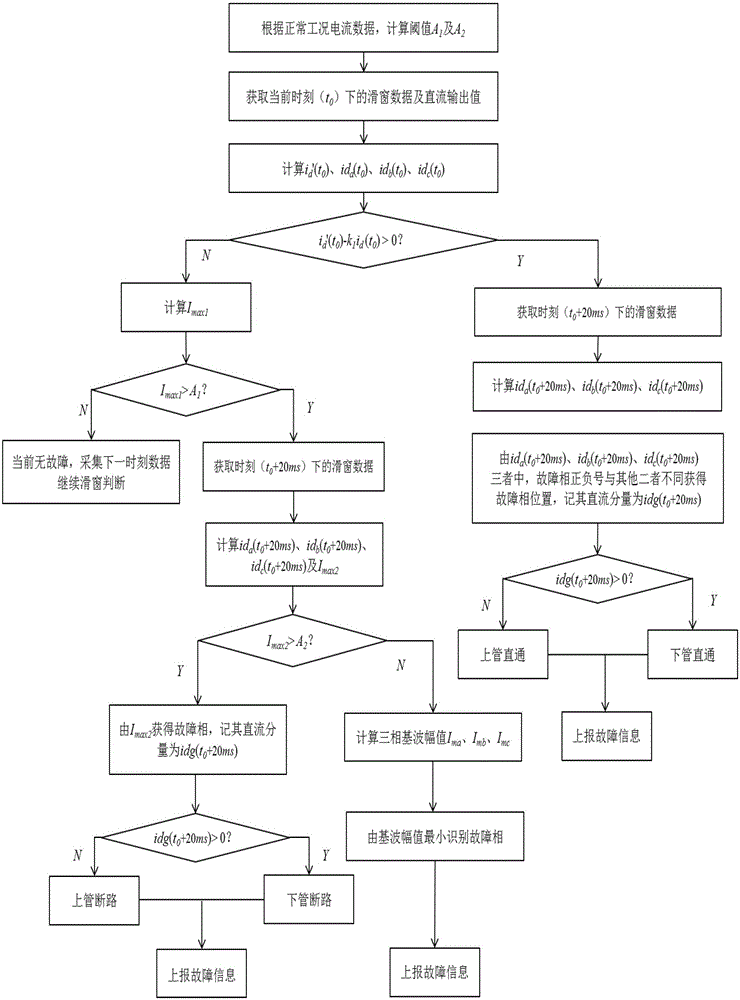

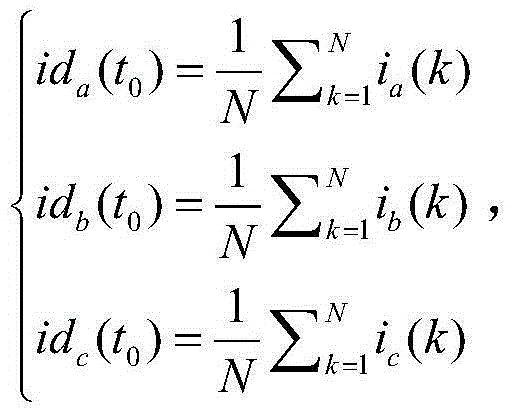

[0032] like figure 1 Shown is a schematic structural diagram of the rectifier, which is a full-bridge rectifier with three upper bridge arms and three lower bridge arms. The input terminal of the rectifier is a three-phase AC input, which are A phase, B phase and C phase respectively. In the three-phase input of the rectifier, each phase input has two bridge arms, which are divided into upper bridge arm and lower bridge arm. Each bridge arm One thyristor is connected in series on the arm, so the rectifier always has six thyristors. Three current detection points are respectively set on the three-phase input line of the rectifier, corresponding current acquisition devices are set at the current detection points, and current sensors for collecting DC current are also set on the DC output line of the rectifier. The three current detection points at the terminal and the current acquisition point at the output end are all connected to a diagnostic device, and the diagnostic device...

Embodiment 2

[0061] In Embodiment 1, the fault judgment method of the rectifier is: judging i d '(t 0 ) and k 1 × i d (t 0 ) size, when i d '(t 0 )>k 1 × i d (t 0 ), it is determined that the rectifier has a thyristor shoot-through fault, when i d '(t 0 )≤k 1 × i d (t 0 ), and when I max1 Greater than or equal to the preset threshold A 1 , the rectifier has an open circuit fault. In this embodiment, only the thyristor straight-through fault is judged for the rectifier, that is, there are only the following steps: when i d '(t 0 )>k 1 × i d (t 0 ), it is determined that the rectifier has a thyristor shoot-through fault. The specific implementation of this step has been described in detail in Embodiment 1, and will not be repeated here.

Embodiment 3

[0063] In Embodiment 1, the fault judgment method of the rectifier is: judging i d '(t 0 ) and k 1 × i d (t 0 ) size, when i d '(t 0 )>k 1 × i d (t 0 ), it is determined that the rectifier has a thyristor shoot-through fault, when i d '(t 0 )≤k 1 × i d (t 0 ), and when I max1 Greater than or equal to the preset threshold A 1 , the rectifier has an open circuit fault. In this embodiment, only the thyristor open-circuit fault judgment is performed on the rectifier, that is, only the following steps are performed: when i d '(t 0 )≤k 1 × i d (t 0 ), and when I max1 Greater than or equal to the preset threshold A 1 , the rectifier has an open circuit fault. The specific implementation of this step has been described in detail in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com