Simulation training device for installing and trouble-shooting process of machine tool electrical control circuit

A technology of electrical control and troubleshooting, which is applied to the simulation device, simulator, transportation and packaging of space navigation conditions, etc. It can solve the problems of lack of on-site sense for students, less training equipment, and inability to reflect the comprehensiveness of machine tool electrical control troubleshooting , to achieve the effect of saving teaching space and capital investment, reducing the probability of safety accidents, and improving the teaching environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

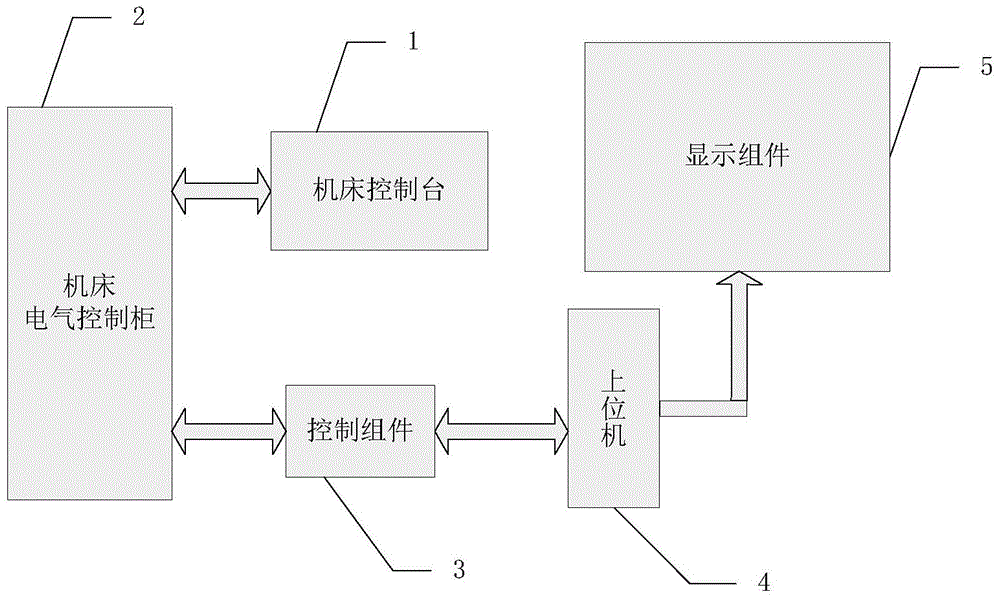

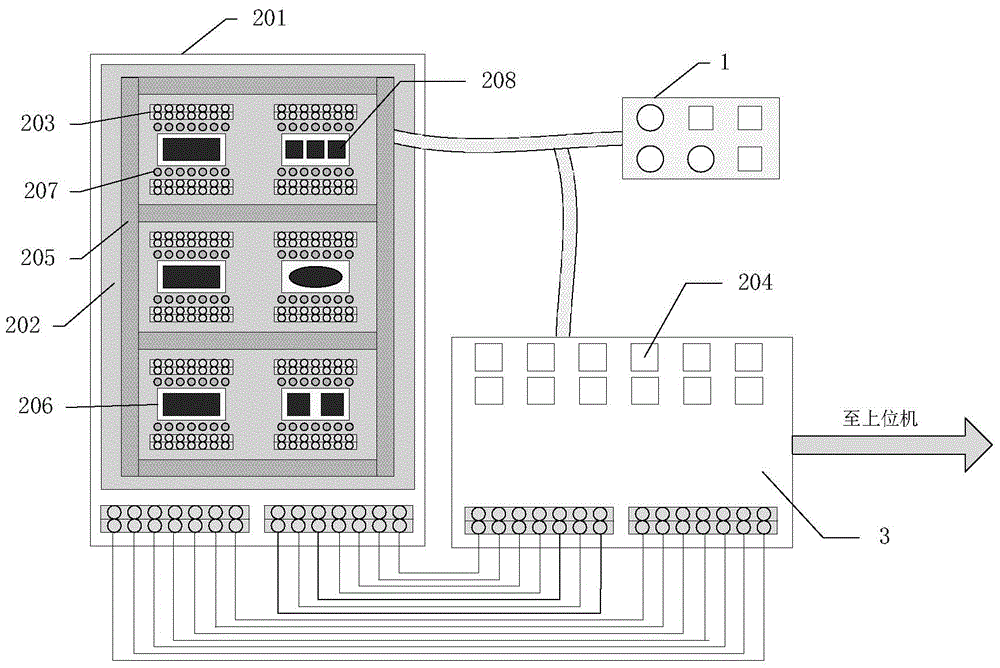

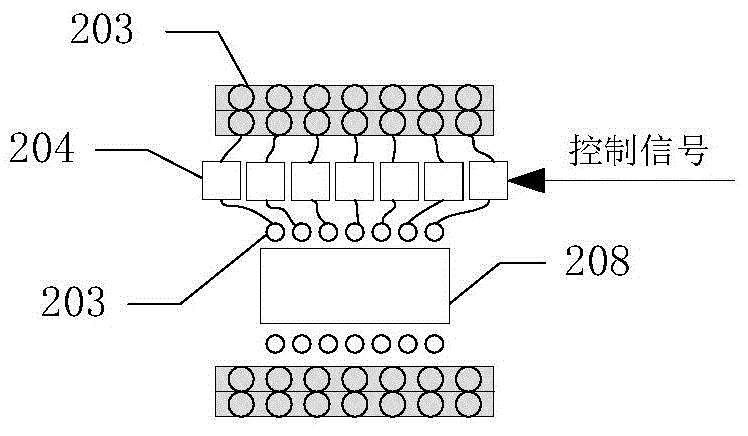

[0023] like Figure 1 to Figure 4 As shown, the machine tool electrical control circuit installation and troubleshooting simulation training device of this embodiment includes a machine tool console 1, a machine tool electrical control cabinet 2, a control component 3, a host computer 4 and a display component 5 connected in sequence, and the machine tool console 1 Including more than one control switch, the control component 3 includes a voltage detection component for detecting the voltage of the electrical circuit in the electrical control cabinet 2 of the machine tool, and the control component 3 sends a corresponding display signal to the display component 5 according to the voltage detection signal of the voltage detection component to display The corresponding working state of the mechanical parts of the machine tool.

[0024] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com