Double-functional molecular magnet material and synthesis method thereof

A technology of bifunctional molecules and synthesis methods, applied in the field of preparation of molecular magnetic materials, can solve problems such as stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

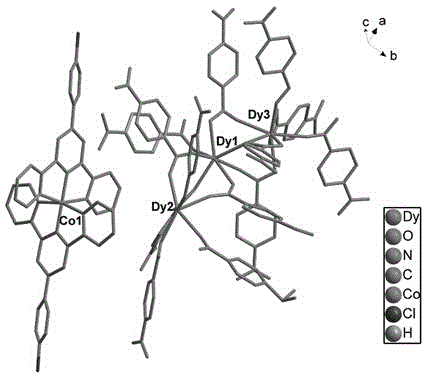

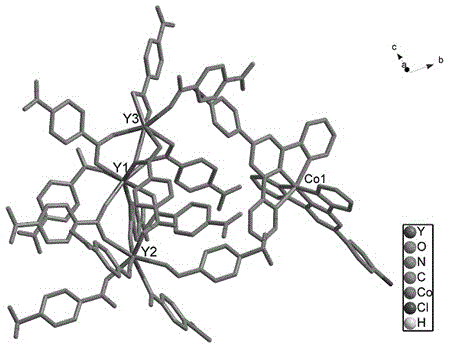

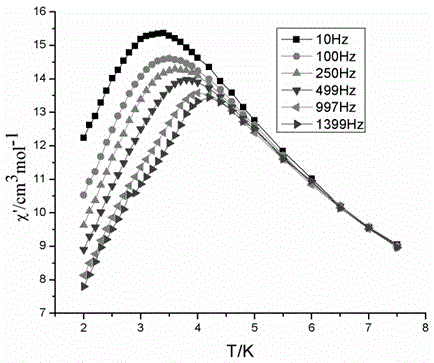

Image

Examples

example 1

[0051] Example 1 Best Reaction Mole Ratio Selection

[0052] According to the synthesis method of the above-mentioned bifunctional molecular magnet, select CoCl 2 ·6H 2 O, 4'-(4-chlorophenyl)-2,2':6',2''-terpyridine ligand, Dy 2 o 3 and p-nitrobenzoic acid were weighed at the molar ratios of 1:2:1:8, 1:1:1:8, and 2:1:1:8, respectively, and reacted at 180°C for 4320min. After the reaction, the products obtained under three different ratios were observed under a microscope:

[0053] Purple-red crystals were all precipitated. Compared with the results, the crystals prepared at the ratio of 1:2:1:8 had the best quality, large size, high purity, and high yield (respectively 70%, 55%, and 38%). In summary, this example shows that the optimal reaction molar ratio for the preparation of bifunctional molecular magnets is 1:2:1:8.

example 2

[0054] The selection of example 2 optimal reaction temperature

[0055] According to Example 1, select the optimal reaction molar ratio CoCl 2 ·6H 2 O: 4'-(4-chlorophenyl)-2,2':6',2''-terpyridine Ligand: Dy 2 o 3 : p-nitrobenzoic acid=1:2:1:8, choose different reaction temperatures 160°C, 180°C, 200°C respectively, and react for 3 days. Colorless transparent needle-like crystals (precipitation of the ligand), the product is not pure; the products obtained at 180°C are all large purple-red crystals, which are phase-pure; at 200°C, the reaction purple-red crystals are small, and there are black impurities on the crystal surface. Comparing the obtained results, 180°C is the optimum reaction temperature of the bifunctional molecular magnet.

example 3

[0056] The selection of example 3 optimal response time

[0057] According to examples 1 and 2, choose the best reaction ratio 1:2:1:8, the best reaction temperature is 180°C, and choose different reaction times: 2 days, 3 days, and 4 days, and it is found that the crystals obtained after 2 days of reaction The crystals were small and the yield was low at 40%; the crystals obtained after 3 days of reaction were large and very pure with a yield of 70%; after 4 days of reaction, the resulting product was charred, most of which were twins, and could not be tested. Comparing the results, the best response time is 3 days.

[0058] Based on examples 1, 2, and 3, the best preparation condition for bifunctional molecular magnets is CoCl 2 ·6H 2 O: 4'-(4-chlorophenyl)-2,2':6',2''-terpyridine Ligand: Dy 2 o 3 : Under the condition of p-nitrobenzoic acid=1:2:1:8, react at 180°C for 3 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com