Keyboard and its preparation method and application

A keyboard and keycap technology, which is applied in the direction of telephone structure, electrical components, electrical switches, etc., can solve the problems of labor-intensive, need to be deepened, and complicated keyboard production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

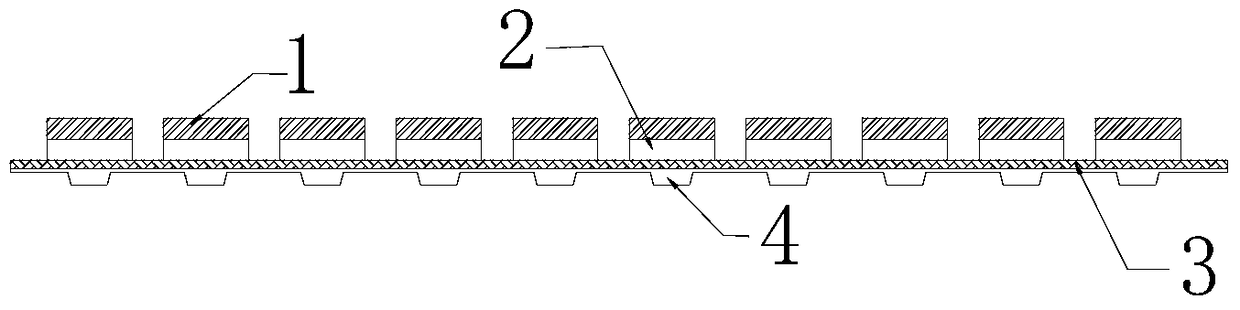

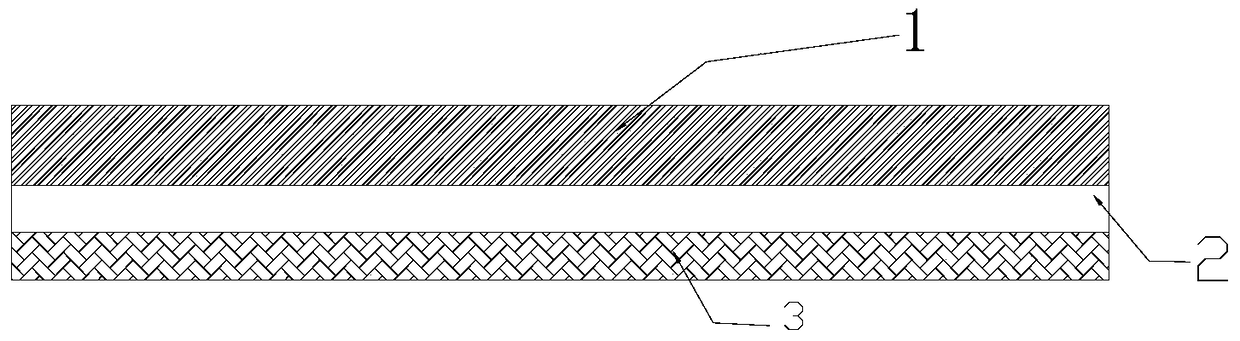

[0040] 1. Bonding of hard rubber sheet and TPU sheet

[0041] The PET hard rubber sheet with a thickness of 0.2 mm and the TPU sheet with a thickness of 0.1 mm are bonded together by glue (UV curable adhesive or hot melt adhesive is usually used). details as follows:

[0042] First place the glue in a vacuum box to evacuate the glue to ensure that there are no air bubbles in the glue, then print the glue on the upper surface of the TPU by screen printing, attach the upper surface of the TPU with the printed glue to the PET hard rubber sheet, and roll it through the roller. Pressing, and then heating or ultraviolet radiation to fully cure the glue to achieve the ideal bonding effect, so as to obtain a hard rubber sheet-substrate composite board. Among them, the rolling process needs to ensure that the rolling is smooth and free of air bubbles. The selected glue needs to be transparent without affecting light transmission, and the thickness of the glue printing is 10 microns. ...

Embodiment 2

[0061] The keyboard is prepared by the same method as in Example 1, the difference is that the hard rubber sheet is a PC sheet and its thickness is 0.5 mm, and the thickness of the TPU sheet is 0.2 mm. During the bonding process of the hard rubber sheet and the substrate, glue The thickness of the printing is 8 microns, the temperature of the upper mold is 115°C, the temperature of the lower mold is 95°C, and the molding pressure is 120kg / cm 2 .

Embodiment 3

[0063] The keyboard is prepared by the same method as in Example 1, the difference is that the hard rubber sheet is a PMMA sheet and its thickness is 0.8 mm, and the thickness of the TPU sheet is 0.15 mm. During the bonding process of the hard rubber sheet and the substrate, glue The thickness of the printing is 5 microns, the temperature of the upper mold is 110°C, the temperature of the lower mold is 90°C, and the molding pressure is 110kg / cm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com