Composite structure and fabrication method of magnetic field regulating LED luminous brightness

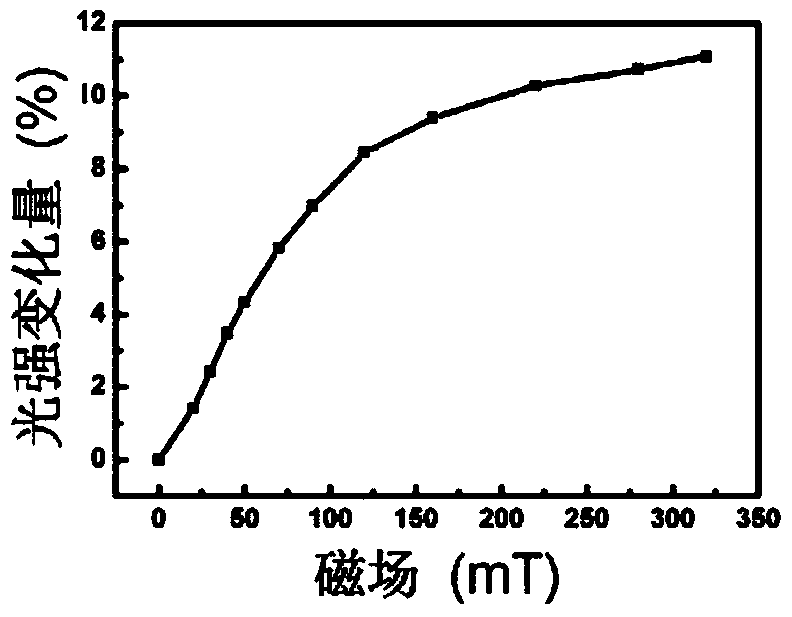

A composite structure, luminous brightness technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing luminous efficiency, red shift, etc., and achieve the effect of low material purity requirements, high mechanical strength, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

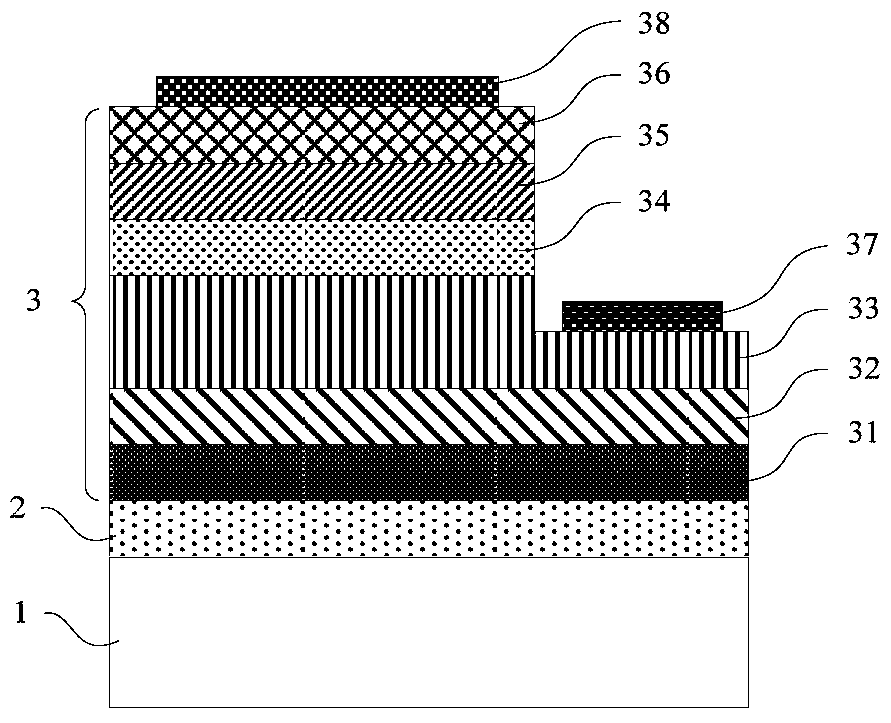

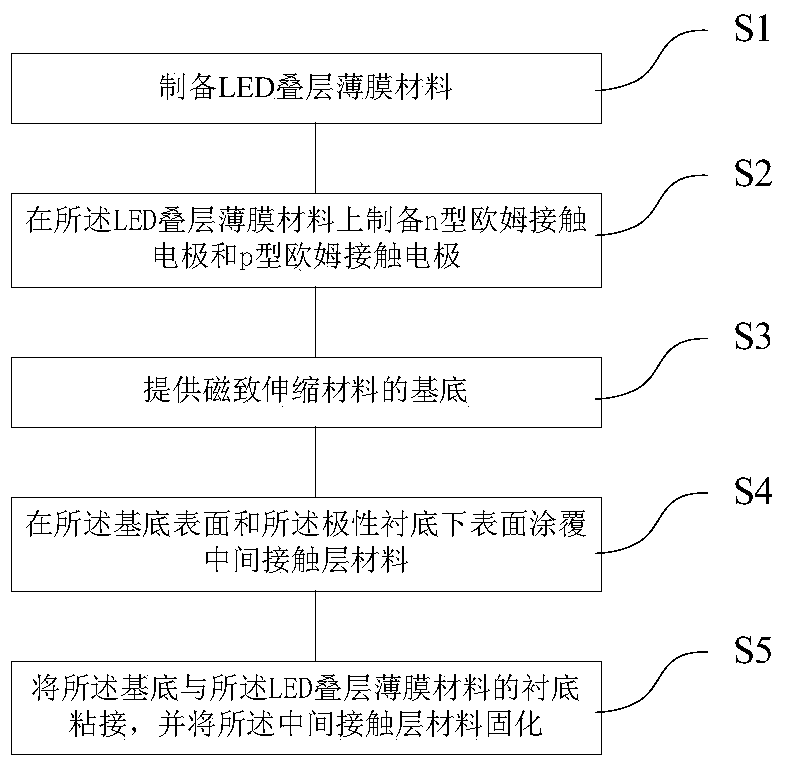

[0063] according to figure 2 The flow chart shown is to make a composite structure that regulates the luminance of blue LEDs by a magnetic field, and the following steps are performed in sequence:

[0064] (a) Epitaxially grow a 2 μm thick GaN buffer layer and a 3 μm thick n-type GaN conductive layer (doped with Si, n-type doping concentration of 3*10 18 / cm 3 ), five 2nm thick In 0.15 Ga 0.85 N / 15nm thick GaN quantum well strained active region, 50nm thick p-type Al 0.1 Ga 0.9 N electron blocking layer and 100nm thick p-type GaN conductive layer to obtain blue LED stacked thin film material;

[0065] (b) using micromachining photolithography means to make mesa etching patterns on the blue LED laminated film material substrate;

[0066] Carrying out dry etching on the patterned blue LED stacked film material substrate, the etching depth reaches the n-GaN conductive layer, and the n-GaN conductive layer is etched by 500nm to form an etching mesa;

[0067] Fabricate n-Ga...

Embodiment 2

[0072] according to figure 2 The flow chart shown is to make a composite structure that regulates the luminance of green LEDs by a magnetic field, and the following steps are performed in sequence:

[0073] (a) Epitaxial growth of 2 μm thick GaN buffer layer and 3 μm thick n-type GaN conductive layer (doped with Si, n-type doping concentration of 3*10 18 / cm 3 ), seven 2nm thick In 0.3 Ga 0.7 N / 12nm thick GaN quantum well strained active region, 50nm thick p-type Al 0.05 Ga 0.95 N electron blocking layer and 100nm thick p-type GaN conductive layer to obtain green LED laminated film material;

[0074] (b) using micromachining photolithography means to make mesa etching patterns on the green LED laminated film material substrate; dry etching the patterned green LED laminated film material substrate, engraving The etching depth reaches the n-GaN conductive layer, and the n-GaN conductive layer is etched by 500nm to form an etching mesa; n-GaN ohmic contact electrodes Ti / Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com