MEMS Microphone

A micro-electromechanical system and microphone technology, which is applied in the direction of electrostatic transducer, microphone, etc., can solve the problem that the diaphragm 108 cannot work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention considers that the micro-particles of the traditional MEMS microphone may enter the cavity through the sound hole, and then enter the cavity through the through hole, which may cause the performance of the diaphragm to decrease, or even fail to work. The present invention proposes multiple embodiments to facilitate description, but is not limited to the cited embodiments, and appropriate combinations are also allowed among the multiple listed embodiments.

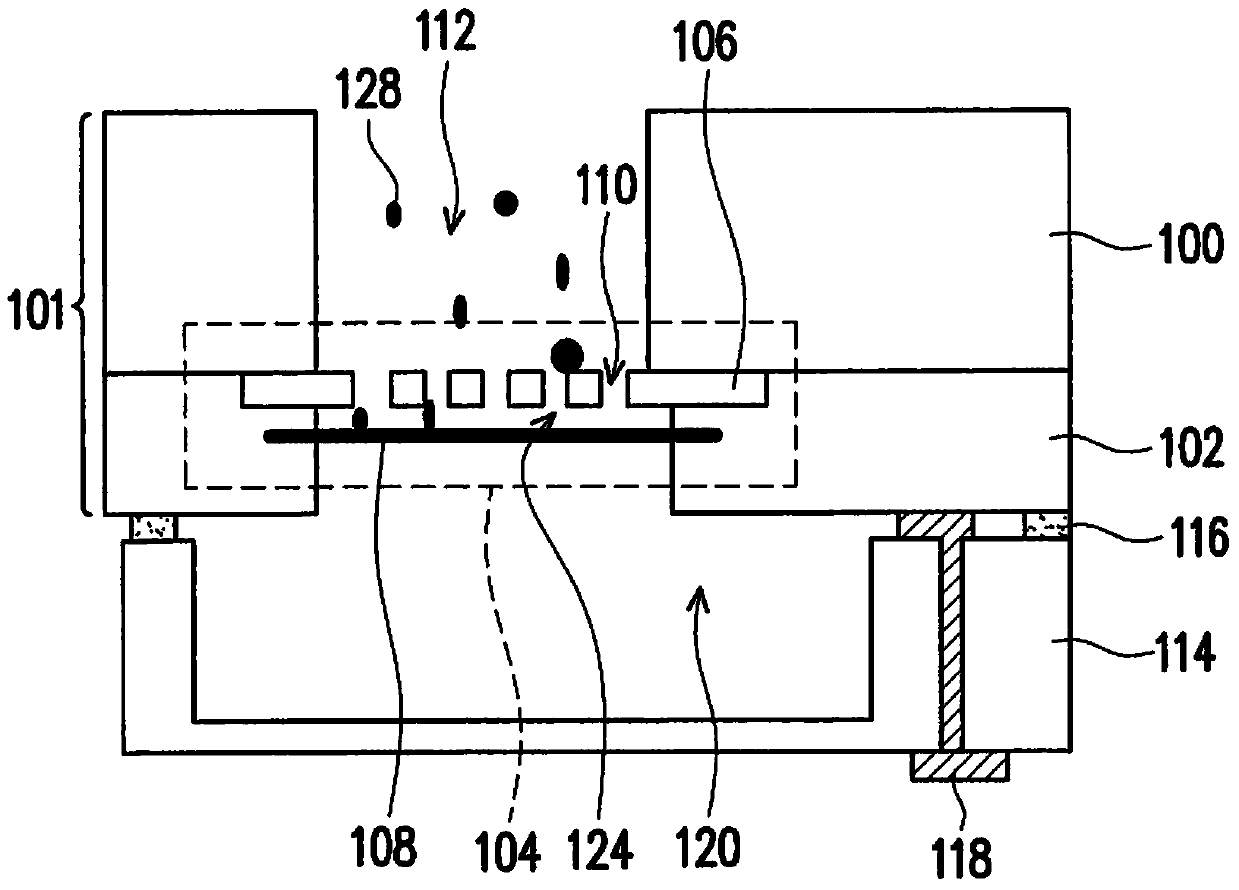

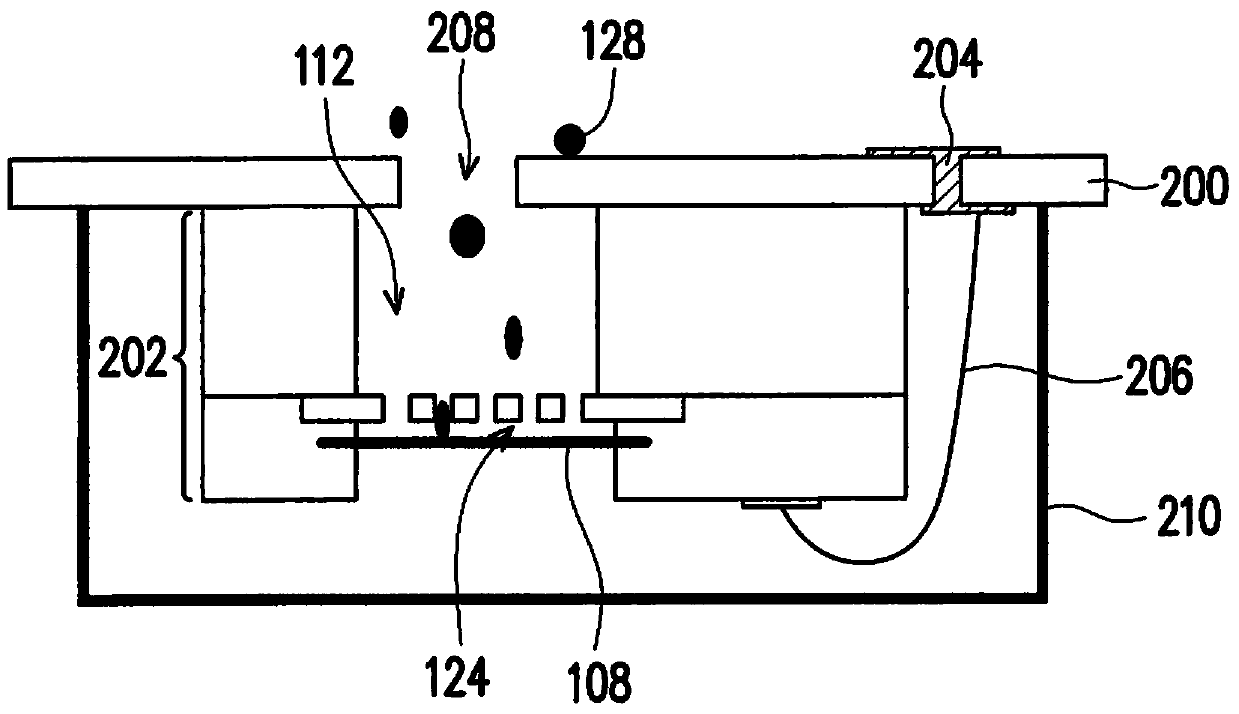

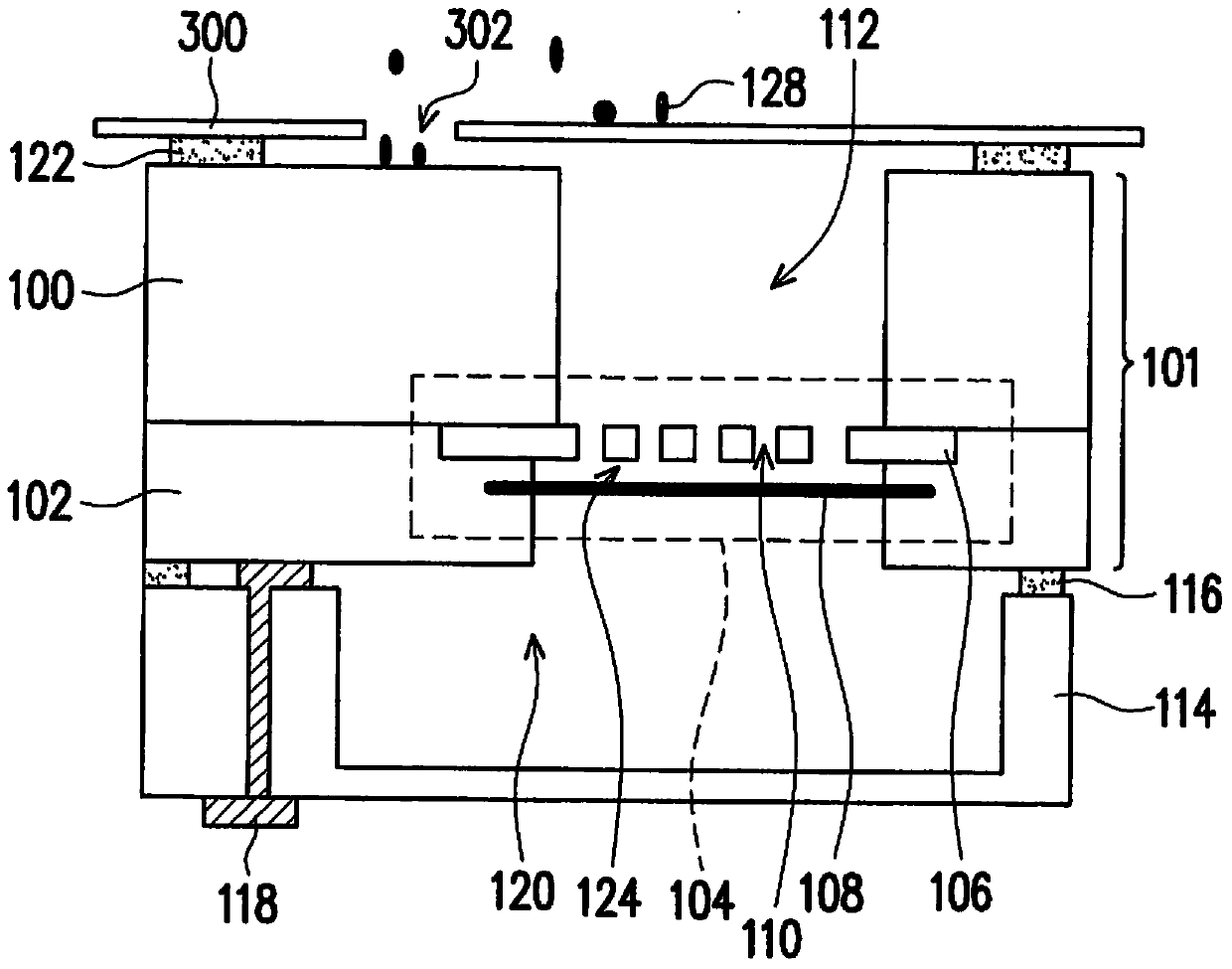

[0042] image 3 is a schematic cross-sectional view of a MEMS microphone according to an embodiment of the present invention. Figure 4 is according to image 3 Schematic diagram of the top perspective structure of a part of the microelectromechanical system microphone structure. refer to image 3 and Figure 4 , the MEMS microphone structure includes a MEMS structure 101 with a substrate 100 , a backplate 106 and a diaphragm 108 , wherein the substrate 100 has a cavity 112 , and the backpla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com