Method for producing zirconia colloids

A technology of zirconia and zirconium oxychloride, applied in zirconia, chemical instruments and methods, colloidal chemistry, etc., can solve problems such as unfavorable economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

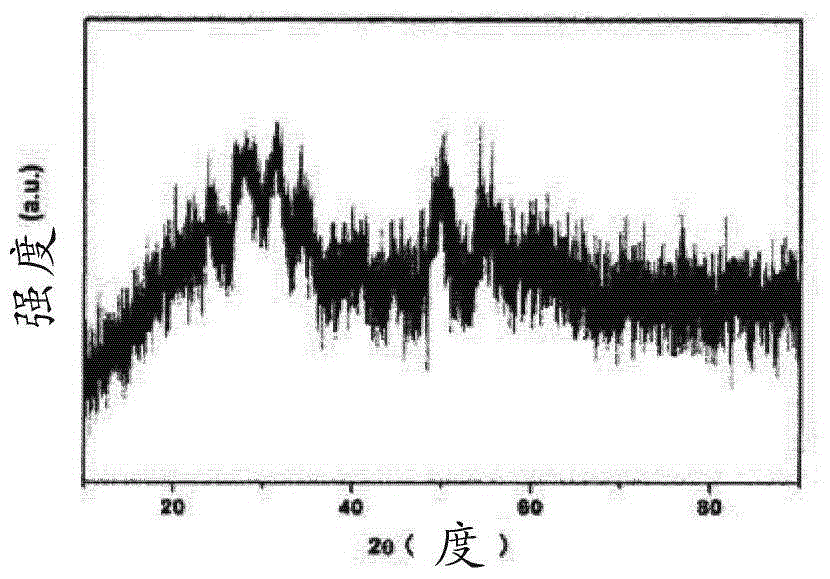

Image

Examples

Embodiment Construction

[0015] As mentioned above, the present invention is directed to a method for producing a colloidal suspension of zirconia particles comprising the following successive steps:

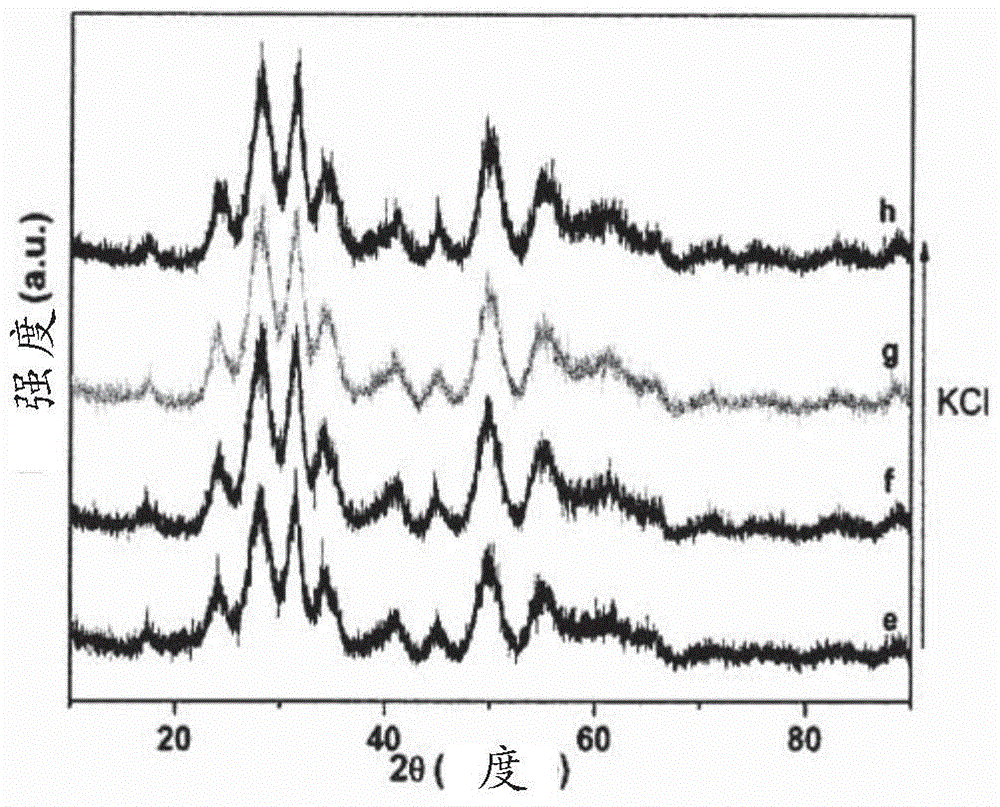

[0016] a) subjecting a mixture of zirconium oxychloride and alkali metal halide in an aqueous solvent to a hydrothermal treatment at a temperature above 150° C. in order to obtain a suspension in the form of a two-phase mixture comprising a A seed slurry and a supernatant, and

[0017] b) Desalting the suspension without first peptizing it to form a colloidal suspension of zirconia.

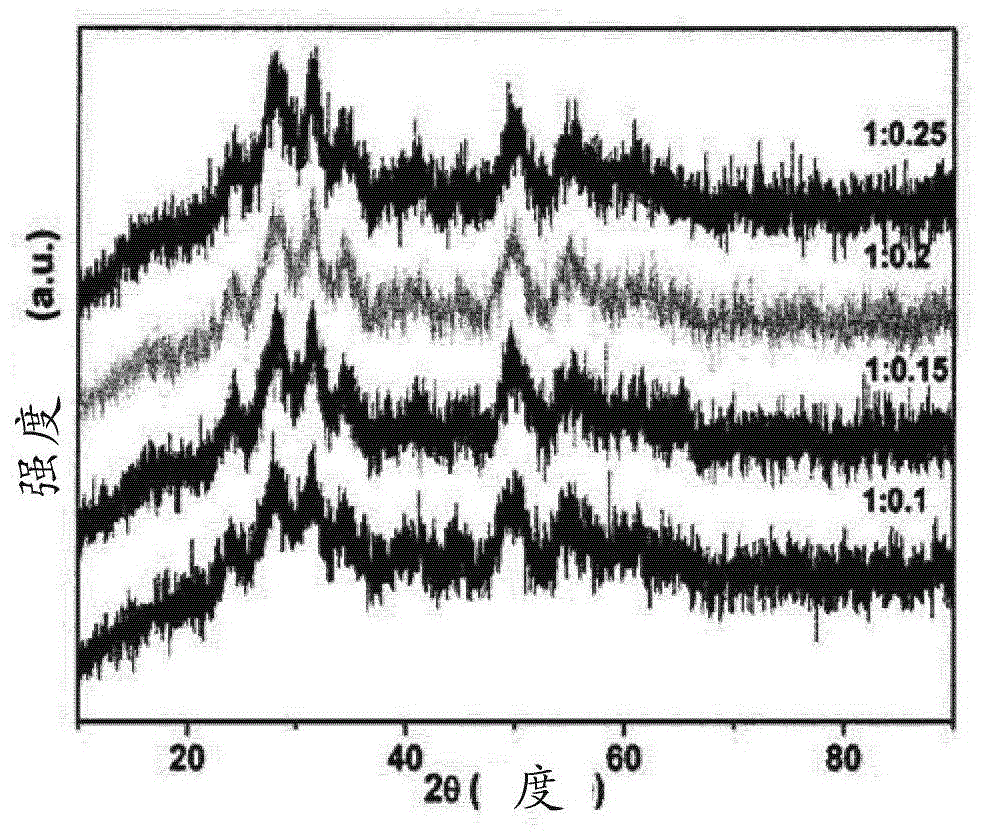

[0018] In the first step of the method, zirconium oxychloride is used as a zirconium precursor. As shown in the examples below, experiments have shown that this precursor results in better dispersed zirconia than when other sources of zirconium, such as zirconium nitrate, are used. Zirconium oxychloride is blended with a mineralizer, an alkali metal halide. The choice of this mineralizer is also critical, as experiments...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com