Paper strip type pot seedling transplanting operation automatic seedling supply and cutting mechanism

A strip-type, pot seedling technology, applied in the field of agricultural machinery, can solve problems such as many operating failures, low operating efficiency, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

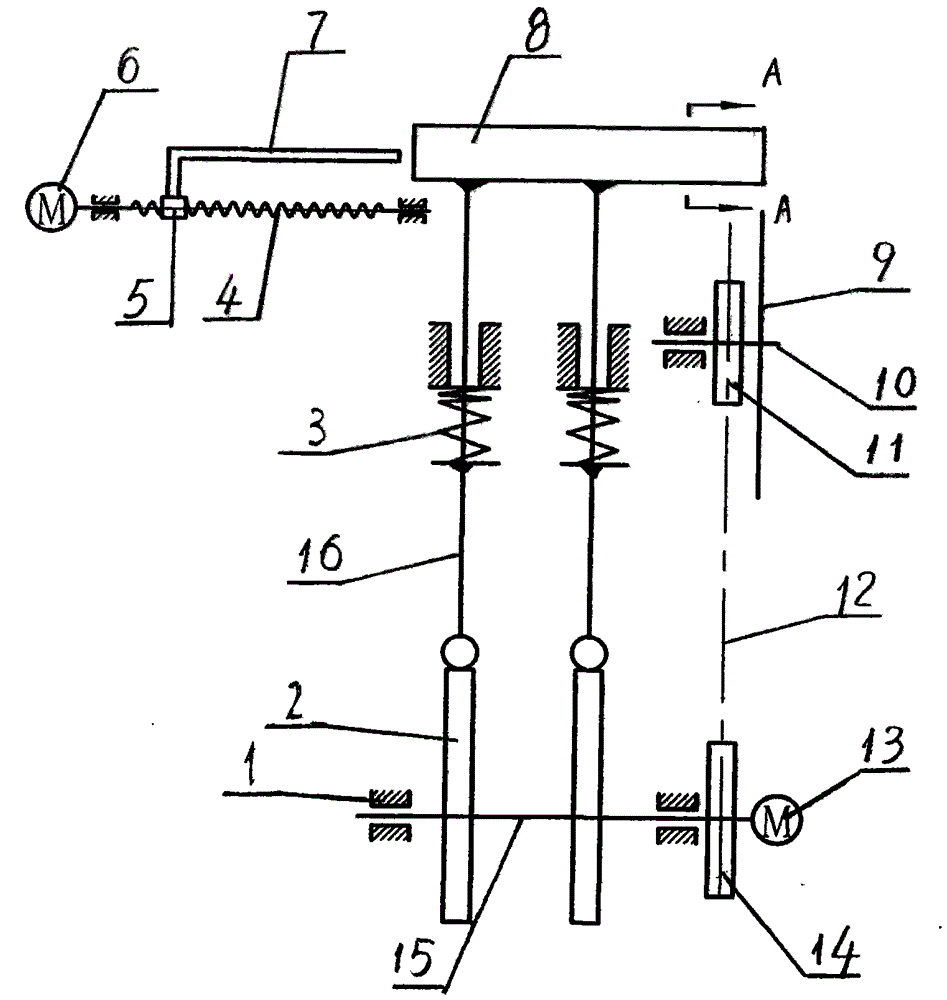

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A paper-based strip-type pot seedling transplanting operation automatic feeding and cutting mechanism, on the frame body 1, a cutter head shaft 10, a cam shaft 15 and a lead screw 4 are installed rotatably parallel to the horizontal direction. The sawtooth cutter head 9 and the driven wheel 11 are fixedly installed on the cutter head shaft 10, two cams 2 are fixedly arranged symmetrically on the cam shaft 15, the driving wheel 14 is fixed on the cam shaft 15, and the transmission belt 12 is sleeved on the On the moving wheel 11 and the driving wheel 14, the motor 13 is connected with the camshaft 15 to drive the camshaft 15 to rotate; on the frame body 1, two ejector rods 16 that are perpendicular to the camshaft 15 and can move up and down are assembled, The two push rods 16 are equipped with pressure springs 3 respectively, the lower end surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com