Additive used for quick-frozen pastries

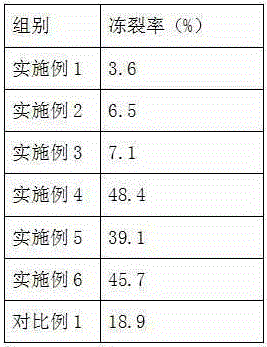

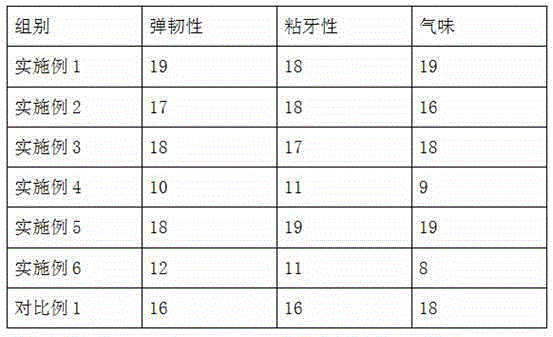

A technology for quick-frozen pastries and additives, which can be used in applications, food ingredients as taste improvers, food preparation and other directions, can solve the problems of intolerance to re-steaming, poor taste, cracking of pastries, etc., and achieve the effect of low freezing cracking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

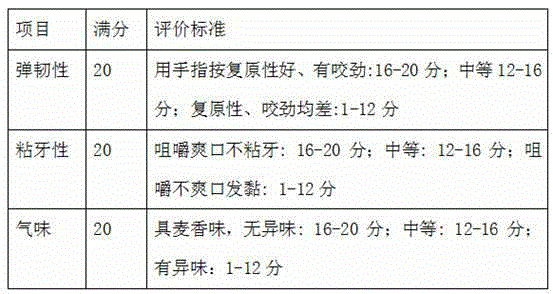

Examples

Embodiment 1

[0015] Embodiment 1: a kind of additive for quick-frozen pastry, comprises the raw material of following weight portion:

[0016] Catechin: 4 parts, paeonol 1.5 parts, cinnamyl acetate 15 parts, ryeposide B8 parts, xylobiose 65 parts, maltitol 25 parts, β-carotene 18 parts, L-cysteine salt 3 parts salt, 35 parts starch acetate, 15 parts fumaric acid, 10 parts sodium alginate, 28 parts xanthan gum;

[0017] Its preparation method is as follows:

[0018] 1) Mix catechin, ryeposide B, maltitol, β-carotene, L-cysteine hydrochloride, and starch acetate and freeze at -15°C for 12 hours to obtain mixture a;

[0019] 2) Heat paeonol to 65°C, then add cinnamyl acetate, mix well and then add xylobiose to obtain mixture b;

[0020] 3) Mix mixture a and mixture b, then add fumaric acid, sodium alginate, and xanthan gum, and mix well to obtain the product.

Embodiment 2

[0021] Embodiment 2: a kind of additive for quick-frozen pastry, comprises the raw material of following weight portion:

[0022] 2 parts of catechin, 0.5 parts of paeonol, 10 parts of cinnamyl acetate, 5 parts of beege saponin B, 50 parts of xylobiose, 20 parts of maltitol, 10 parts of β-carotene, L-cysteine hydrochloride 1 part of salt, 20 parts of acetate starch, 10 parts of fumaric acid, 5 parts of sodium alginate, 10 parts of xanthan gum;

[0023] Its preparation method is as follows:

[0024] 1) Mix catechin, ryeposide B, maltitol, β-carotene, L-cysteine hydrochloride, and starch acetate and freeze at -10°C for 10 hours to obtain mixture a;

[0025] 2) Heat paeonol to 60°C, then add cinnamyl acetate, mix well and then add xylobiose to obtain mixture b;

[0026] 3) Mix mixture a and mixture b, then add fumaric acid, sodium alginate, and xanthan gum, and mix well to obtain the product.

Embodiment 3

[0027] Embodiment 3: a kind of additive for quick-frozen pasta, comprises the raw material of following weight portion:

[0028] 5 parts of catechin, 2.5 parts of paeonol, 20 parts of cinnamyl acetate, 10 parts of ryeposide B, 75 parts of xylobiose, 30 parts of maltitol, 25 parts of β-carotene, L-cysteine hydrochloride 5 parts of salt, 50 parts of acetate starch, 20 parts of fumaric acid, 15 parts of sodium alginate, 38 parts of xanthan gum;

[0029] Its preparation method is as follows:

[0030] 1) Mix catechin, ryeposide B, maltitol, β-carotene, L-cysteine hydrochloride, and starch acetate and freeze at -20°C for 15 hours to obtain mixture a;

[0031] 2) Heat paeonol to 70°C, then add cinnamyl acetate, mix well and then add xylobiose to obtain mixture b;

[0032] 3) Mix mixture a and mixture b, then add fumaric acid, sodium alginate, and xanthan gum, and mix well to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com