Movable coffee brewing head structure and coffee maker using same

A brewing head and coffee technology, which is applied to the field of coffee machines with a movable coffee brewing head structure, can solve the problems of laborious operation, complicated structure, high production and assembly costs, and achieves a reduced manufacturing cost, reduced volume, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

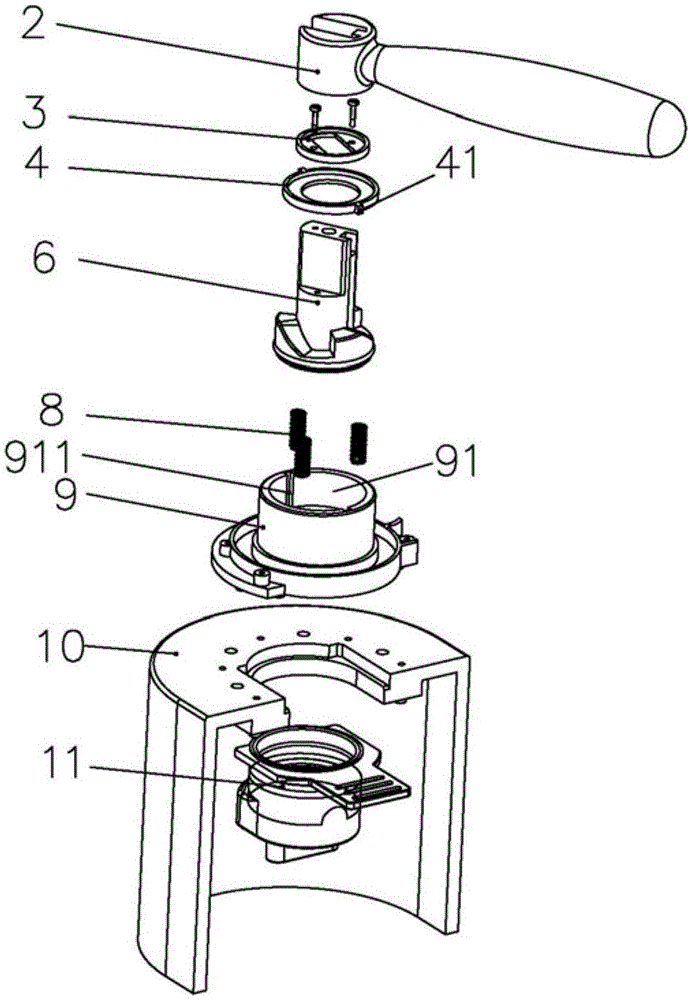

[0041] figure 1 An exploded view of a first embodiment of the movable coffee brewing head structure according to the present invention is schematically shown. The structure of the movable coffee brewing head mainly includes: a brewing head 6 and a brewing head support 9 .

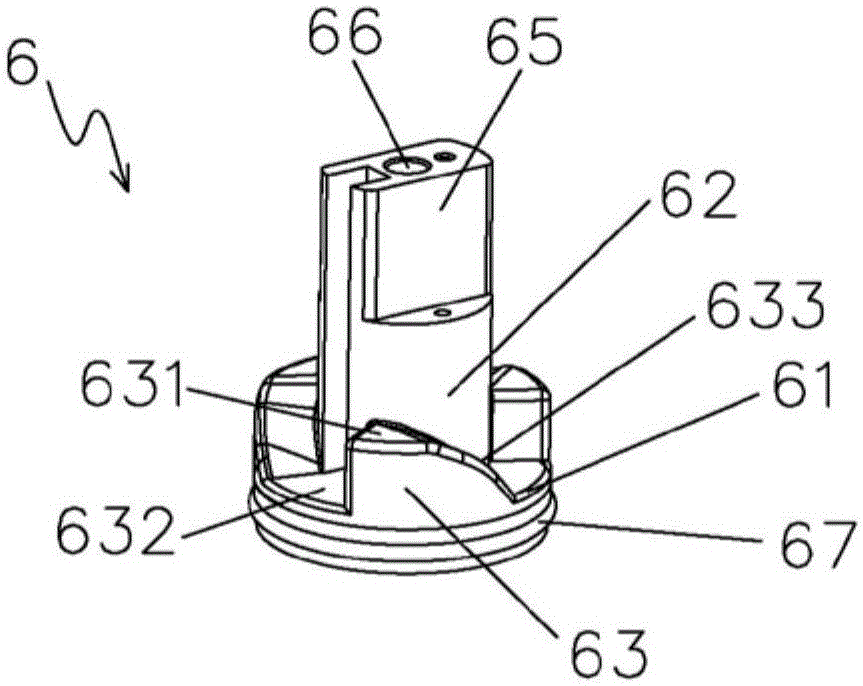

[0042] Please be specific as figure 2 As shown, the brewing head 6 has a circular base 61 , a cylindrical connecting portion 62 is provided in the center above the base 61 , and a tongue 65 is integrally formed on the connecting portion 62 . There is a step 64 between the connecting portion 62 and the tongue portion 65 . At least two sliding blocks 63 are provided on the upper edge of the base 61 . exist figure 2 In the shown embodiment, the number of sliders 63 is three, but not limited thereto. The sliders 63 are wedge-shaped, and the sliders 63 face in the same direction, that is, they all face clockwise or counterclockwise.

[0043]The connecting portion 62 is sleeved with the limiting piece 4 a...

no. 2 example

[0056] Figure 6 Schematically showing an exploded view of a second embodiment of the movable coffee brewing head structure according to the present invention. Compared with the first embodiment, the improvement of the second embodiment is that: the drive wheel 7 and the driven wheel 1 are added to the transmission assembly, so as to change the rotation direction of the handle, which is beneficial to reduce the overall volume of the coffee machine and facilitate Storage, in addition, the use of gear transmission can improve the transmission accuracy and ensure that the brewing head can accurately reach the desired position, which is very practical.

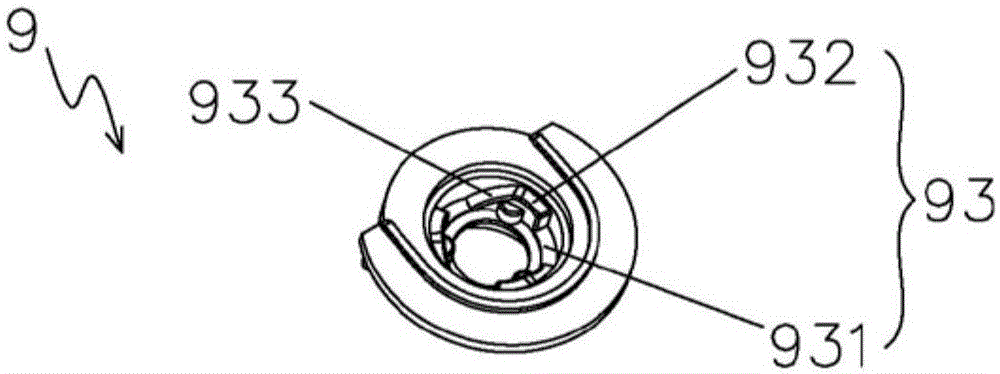

[0057] The specific improvements are as follows: Figure 7 As shown, one side of the accommodating cavity 91 of the brewing head bracket 9 is also provided with a bearing part 92, and the upper part of the bearing part 92 is provided with a half-axis hole 94 and two sides of the half-axis hole 94. Briquetting block seat 95. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com