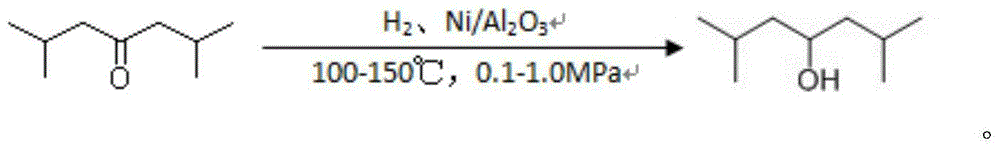

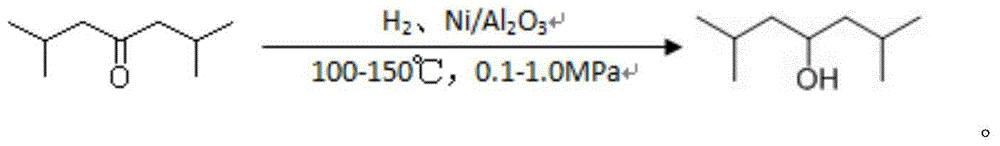

Loaded catalyst and application thereof in diisobutyl carbinol preparation

A supported catalyst and catalyst technology, which is applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems of high reaction pressure, difficult storage, and many side reactions, and achieve high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Ni / γ-Al 2 o 3 As a catalyst, the content of Ni is 35%, the content of Mn is 0.5%, under the condition of reaction temperature 110℃, reaction pressure 0.2Mpa, space velocity 0.1, 1m 3 The catalyst passes through 0.1m within 1h 3 The yield of diisobutyl carbinol obtained after the reaction raw materials reaches 90.25%, by-product 1 is 0.57%, by-product 2 is 0.39%, and diisobutyl ketone is 8.79%.

Embodiment 2

[0015] Ni / γ-δAl 2 o 3 As a catalyst, the content of Ni is 30%, the content of Co is 1%, under the conditions of reaction temperature 115°C, reaction pressure 0.2Mpa, space velocity 0.1, 1m 3 The catalyst passes through 0.1m within 1h 3 The yield of diisobutyl carbinol obtained after the reaction raw materials reaches 90.26%, by-products are 0.37%, and diisobutyl ketone is 9.37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com