Tile brick edge grinding machine

A technology of edge grinding machine and tiles, which is applied to machine tools suitable for grinding the edge of workpieces, parts of grinding machine tools, grinding machines, etc., which can solve the problems of increased processing costs, large cooling water consumption, and high sewage treatment costs. Achieve the effect of saving processing costs, improving high-quality rate, and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

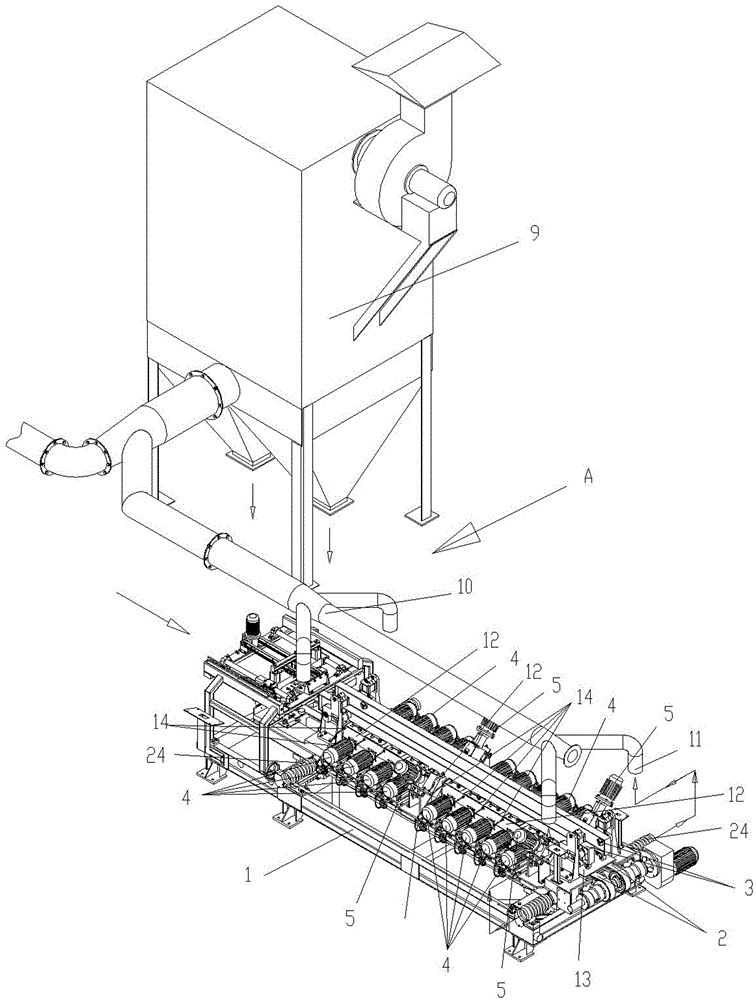

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

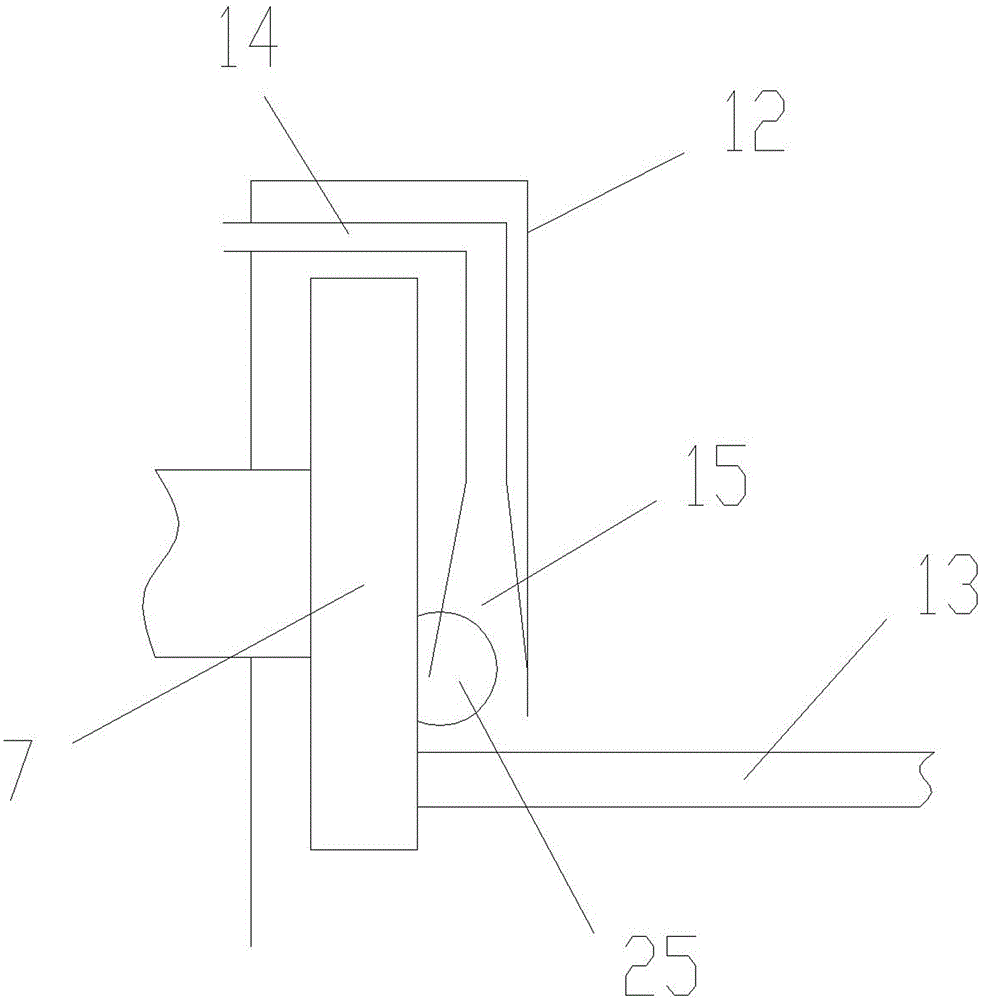

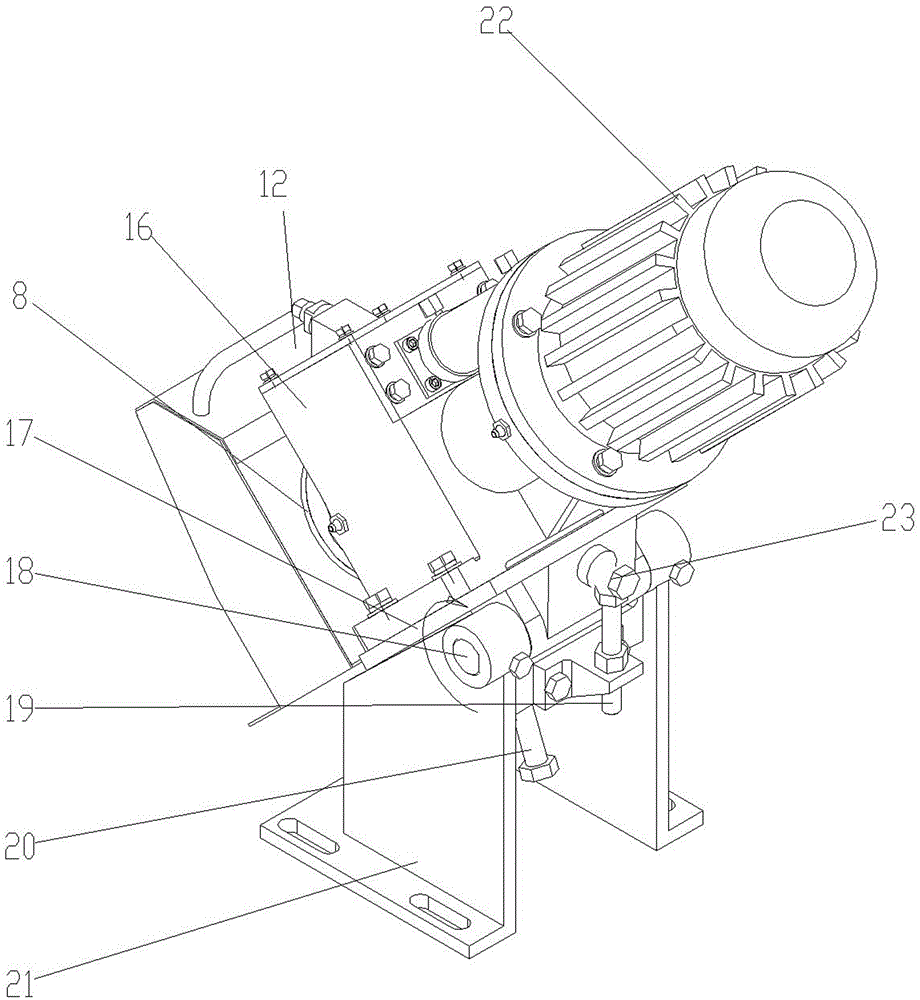

[0014] Such as figure 1 , 2 As shown, the present invention includes a frame 1, a tile conveying device 2 arranged on the frame 1, a tile pressing device 3 arranged on the frame 1, an edge grinding device 4, a chamfering device 5 and a cooling device A , which is characterized in that several (2-4) edge grinding devices 4 and several (3-5 ) is located at the edging device 4 at the rear part of the tile conveying device 2, and a chamfering device 5 is installed between the edging device 4 at the front part of the tile conveying device 2 on each side and the edging device 4 at the rear part. A chamfering device 5 is installed behind several edging devices 4 at the rear section of each side tile conveying device 2, and the cooling device A includes a dust collector 9, a dust extraction horizontal pipe 10 communicated with the dust collector 9, and a suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com