Mobile wheel loading and unloading robot

A robot and mobile technology, applied in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of manual operation, low work efficiency and large labor volume of the I-shaped wheel, so as to save the cost of human resources and eliminate potential safety hazards. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

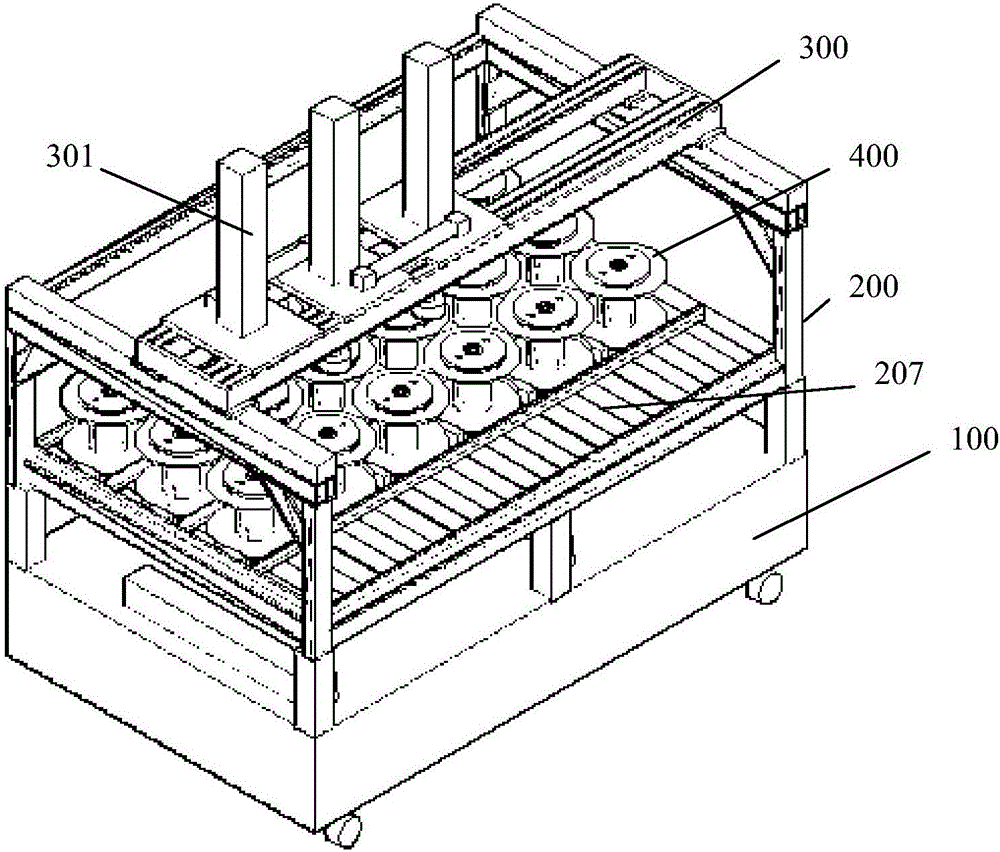

[0032] The existing spools need to be loaded and unloaded when they are transported from the previous process to the next process. In the traditional technology, the loading and unloading of the spools is manual operation, or the use of power-assisted machinery. The weight can reach hundreds of kilograms, and it generally requires multiple workers to carry it together. The workload is large, the work efficiency is low, the labor intensity is increased, and there are greater safety risks, and the degree of automation is low.

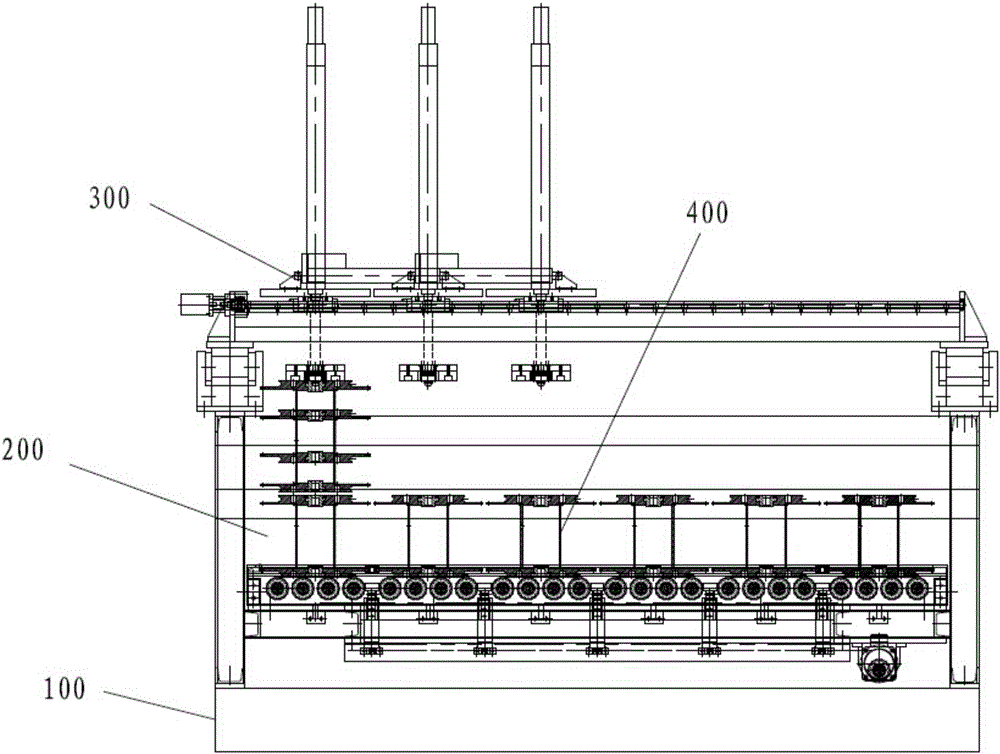

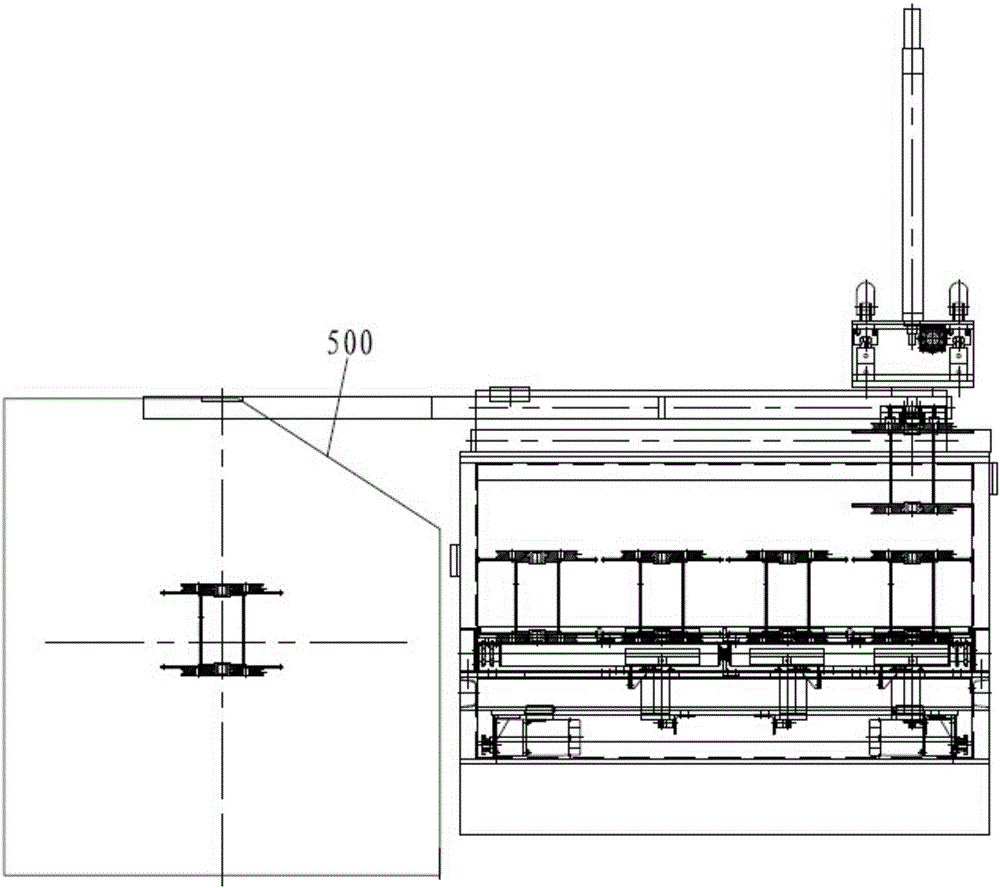

[0033] In view of the deficiencies in the prior art, the present invention provides a mobile wheel loading and unloading robot. By setting a bearing platform on the robot, the bearing platform is docked with the machine conveyor line during work, and the spool is automatically transferred to the robot. By setting up a grabbing device to move the full I-wheels on the load-bearing platform to the machine, or move the empty I-wheels on the machine to the robot t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com