A Traction Power Supply System for Electrified Railway

A traction power supply system, electrified railway technology, applied in power lines, transportation and packaging, vehicle components, etc., can solve the problem of safe operation of trains that affect power supply reliability, large operating overvoltage or overcurrent, traction network and on-board equipment burnout and other problems, to achieve the effect of facilitating daily management, reducing cable consumption, and saving power investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

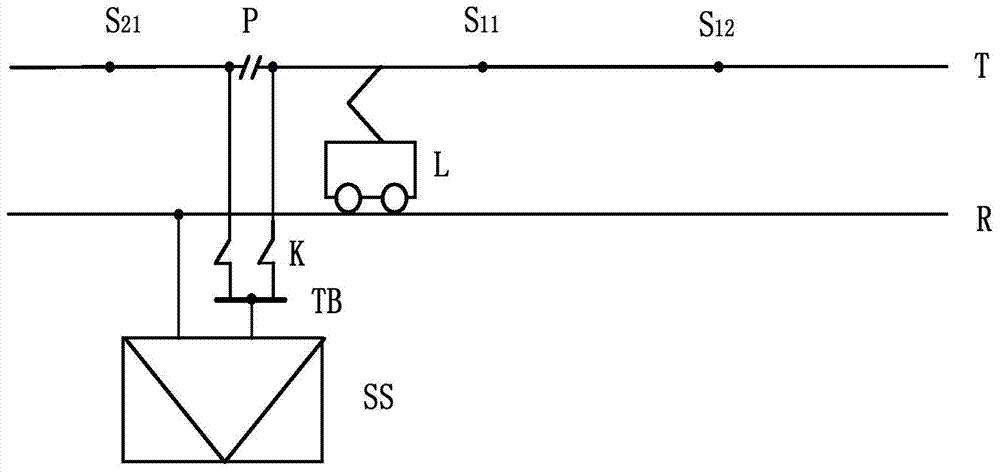

[0032] figure 1Shown is a schematic structural diagram of the direct supply system involved in the present invention. The direct supply system is composed of the traction substation SS and the direct supply traction network. The direct supply traction network is composed of the catenary T and the rail R. The train L receives power between the catenary T and the rail R; The sectionalizer P is set at the exit of the SS, while the catenary generally does not have a sectionalizer S i , but for the convenience of the following description, the subsection S is drawn in the figure i , i=mn, m=1 means the right side of the traction substation SS, m=2 means the left side, n=1,2,...,N, N is the subsection S i number, and the number of segments=N-1, such as figure 1 Medium, S 11 , S 12 , S 21 Wait. In practice, in order to reduce the potential of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com