A system and method for underground cooling, softening and regeneration of high-temperature three-ash water in mines

A regenerative system and high-temperature technology, applied in mining wastewater treatment, ion exchange water/sewage treatment, etc., can solve the problems of main water supply pipeline siphon water shortage, hidden dangers of mine equipment, strong pipelines, etc., to avoid waste of water resources, The effect of saving manpower and material resources and reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

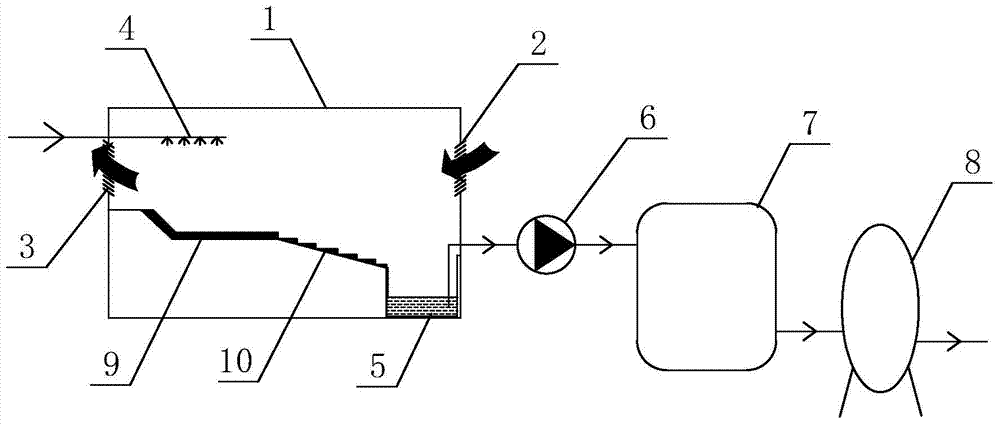

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, an underground cooling, softening and regeneration system for high-temperature three-ash water in a mine includes a return air heat exchange system arranged in an underground return air tunnel, and the return air heat exchange system includes an air inlet 2 and an air outlet arranged at both ends of the tunnel 1 The tuyere 3 is provided with a spray pipe 4 at the top of the roadway 1, and a cold water tank 5 is arranged at the bottom of the roadway 1; the cold water tank 5 is connected to the fully automatic filter 7 through the pipeline through the water pump 6, and the fully automatic filter 7 is connected to the fully automatic filter through the pipeline. The water softener 8 is connected.

[0023] The spray pipe 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com