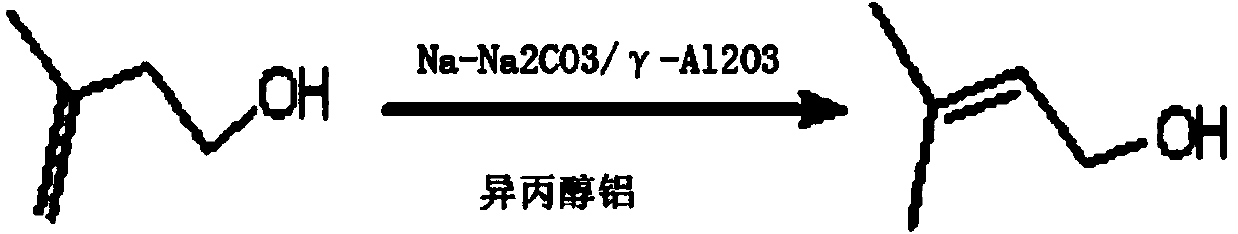

Method for synthesizing prenol from butenol

A technology for prenol and butenol, applied in the field of synthesis of prenol, can solve problems such as inconvenience, and achieve the effects of cost reduction, broad prospects and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Under a nitrogen atmosphere of 0.5MPa, add 650.0 grams of 3-methyl-3-buten-1-ol to the reactor, add 0.65 grams of aluminum isopropoxide, 0.65 grams of Na-Na 2 CO 3 / γ-Al 2 o 3 Solid super strong base, controlled temperature is 110°C, reaction time is 3h, filtered, detected by chromatograph, 468.0 g of 3-methyl-3-buten-1-ol participated in the reaction, and the final product isopentenol 442.6 grams, conversion rate 72.0%, selectivity 94.5%, yield 68.1%.

Embodiment 2

[0019] Under a nitrogen atmosphere of 1MPa, add 650.0 grams of 3-methyl-3-buten-1-ol to the reactor, add 0.43 grams of aluminum isopropoxide, 0.87 grams of Na-Na 2 CO 3 / γ-Al 2 o 3 Solid super base, controlled temperature is 120°C, reaction time is 2h, pumped and filtered, detected by chromatograph, 483.5 grams of 3-methyl-3-buten-1-ol participated in the reaction, and the final product isopentenol 439.9g gram, conversion rate 74.4%, selectivity 91.0%, yield 67.7%.

Embodiment 3

[0021] Under a nitrogen atmosphere of 4MPa, add 650.0 grams of 3-methyl-3-buten-1-ol to the reactor, add 13.5 grams of aluminum isopropoxide, 26.5 grams of Na-Na 2 CO 3 / γ-Al 2 o 3 Solid super strong base, controlled temperature is 120°C, reaction time is 2.1h, pumped and filtered, detected by chromatograph, 475.5 grams of 3-methyl-3-buten-1-ol participated in the reaction, and the final product isopentenol was generated 445.3 grams, selectivity 93.6%, conversion 73.2%, yield 68.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com